SmartCut Fabric Sample Cutting System | A new machine developed by the sister company ChiuVention.

The SmartCut fabric-cutting machine can complete the sampling of fabrics within 3 minutes.

It can be connected with the customer’s ERP or LIMS system docking through the network port, then automatically gets the test item information from the scanning of the bar code. Then SmartCut fabric swatch-cutting machine will lay out the sample graphics of the items to be tested by the standard requirements through a unique algorithm.

Next step, the sample graphics will be projected on the fabric and the SmartCut fabric swatch cutter will start cutting fabric samples, automatically marking the samples as the the customer’s settings.

This Fabric Swatch Cutting Machine is suitable for sampling requirements of dozens of tests such as pilling, tearing strength, water repellency, anti-static, tensile strength, color fastness, flammability, etc. It supports various standards such as GB/T, FZ/T, ISO, EN, JIS L, AATCC, ASTM, CAN, AS, and so on. We also provide other types of Textile Sample Cutting Machines.

Description

Application of SmartCut Fabric Sample Cutting Machine

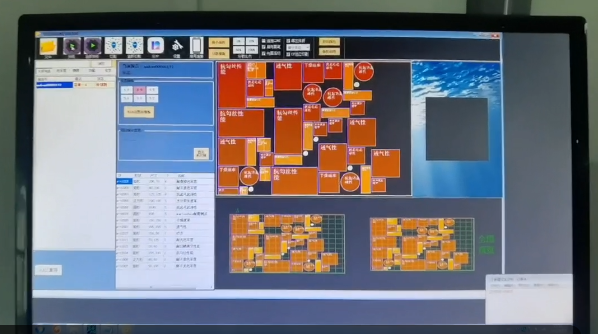

SmartCut Textile Sample Cutting Machine saves 90% of sample cutting time and speeds up the whole test. The cutting is precise and the sample qualification rate is higher. The sample graphic library covers more than 95% of the textile testing items. It meets most sampling requirements, such as abrasion & pilling tests, tearing strength tests, waterproof tests, anti-static tests, tensile strength tests, color fastness tests, etc. Flexible cutting pattern, easier sampling. This Textile Sample Cutting Machine can achieve multi-station cutting (cutting different fabrics at the same time), multi-layer cutting (thickness up to 7mm), shaped cutting (irregular shapes), etc. This Smart Fabric Sample Cutting Machine consists of sample-cutting software, a fabric sample-cutting machine, a computer, and a projector. The working principle: The operator lays out the shapes of cutting samples in the software, then the projector projects the layout onto the working table, and after starting the cutting button, the fabric sample cutting machine can automatically cut out the samples as required.

Strictly cuts the samples according to the standards, ensuring the test is more reliable.

This fabric Fabric Swatch Cutting Machine supports decentralized sampling, trapezoidal sampling, full-width sampling, and 45° sampling, and can cut samples according to the rules such as alignment to the grid and edge. So, the reliability of the test is guaranteed from the sampling.

More precise cutting and higher sample pass rate.

The tungsten steel blade of the SmartCut Fabric Swatch Cutting Machine is sharp and can be rotated 360°, with a sample cutting accuracy of 0.1mm, and a round-trip cutting error rate of less than 0.01mm, i.e. cut grams of specimens accurately.

Saves 5 laborers per year (about $420,000) for large-scale labs.

If you need to cut 100 whole fabric samples per day, the conventional manual cutting requires 3000 minutes, i.e. 6 laborers; while using the SmartCut sample cutting machine, 100 whole samples need only 0.6 laborers, saving 5 laborers per year for the laboratory.

SmartCut Fabric Swatch Cutter can also achieve multi-station cutting (cutting different fabrics at the same time); multi-layer cutting (maximum cutting thickness of 7mm, can cut 1-20 layers); shaped cutting (irregular graphics). It can mark samples.

The Working Process of SmartCut Sample Cutting Machine

(1) Quick entry: This Textile Sample Cutting Machine can be connected to the factory ERP or laboratory LIMS, then scan the code to read the items to be tested and their requirements; You can also manually select the textile testing standards to set up as a package, then next time you can directly open the package;

(2) one-click layout: Click the [layout] button then the fabric sample cutting machine will work, you can choose the mode of [decentralized layout] or the layout of [cut the fabric as the fabric-saving way]; Layout according to standard requirements to ensure the reliability of sampling;

(3) Flexible adjustment: The layout graphics will be projected onto the fabric, you can drag the graphics manually according to the fabric state or change the size of the layout area, and you can modify the number of samples;

(4) One-click cutting: Click the [cutting] button, and the SmartCut sample cutter starts to cut the fabric, it will walk according to the system’s algorithm, according to the path that saves the most time, and cuts the samples that fully conform to the layout; The cutter head can rotate 360°, the blade is sharp and the cutting is precise; At the same time, there is an infrared sensor function, touch emergency stop, to avoid cut accidents; Once sampling is complete, just collect the sample.

Applicable test items and standards of SmartCut Textile Sample Cutting Machine

| Test Items | Corresponding Standards |

| Abrasion & Pilling | GB/T4802、 ISO12945、 JIS L1076、ASTM D4970 |

| Tearing Strength | GB/T3917 、 ISO 13937 、 JIS L1096 、ASTM D751 |

| Water Proof | GB/T4745、ISO 4920、AATCC 22、ISO 9865、JIS L1092 |

| Antistatic Test | GB/T12703 、 GB/T 22042、EN 1149、ISO 6330 |

| Core Suction Height | GB/T21655、JISL1907、ISO6330 |

| Dimensional Stability | GB/T 8629、ISO 6330、JIS L0217、AATCC 135、AS2001.5.4 |

| Elastic Elongation | FZ/T01062、ASTMD3107、JIS L1096、EN 14704 |

| Tensile Strength | GB/T3923、 ISO 13934 、 ASTM D5034、EN 29073-3 |

| Fabric Weight | GB/T4669、ASTM D3776、ISO 3801、JIS K6772、EN 12127 |

| Abrasion Resistance | GB/T21196.2、ISO 12947、ASTM D3884、AS 2001.2.28 |

| Peel Strength | FZ/T80007.1、ISO 8096、JIS L1089、ASTM D2724 |

| Burst Strength | GB/T7742.1、ISO13938-1、ASTM D3786 |

| Seam slippage | GB/T13772.1 、 FZ/T20019、ISO13936 、 JIS L1096 |

| anti-hooking | GB/T11047、BS8479、ASTMD3939 |

| down-proof | GB/T12705 、 GB/T 14272、EN 12132、ISO 6330 |

| Colorfastness to rubbing | GB/T3920、AATCC 8、ISO 105 X12、ASTM D2054、JIS L0849 |

| Colorfastness to sunlight | GB/T8427、AATCC-16(3)、ISO 105-B02、ASTM D6544 |

| Other color fastness items | GB/T、FZ/T、ISO、EN、JISL、AATCC、ASTM、CAN、AS |

| Flammability | GB/T5455、FZ/T01028、ISO 3795、GB 8410、ASTM D5132 |

| other items | …… |

Product model and specification of SmartCut Sample Cutting Machine

| Model | Working Area(cm) | Weight(kg) | Power(kW) | Warranty Period |

| CV517-6060 | 60*60 | 400 | 4.5 | 1 year |

| CV517-1410 CV517-1610 | 140*100/160*100 | 600 | 4.5 | 1 year |

| CV517-1516

| 150*160 | 650 | 4.5 | 1 year |

| CV517-1810 CV517-1812

| 180*100/180*120 | 700 | 4.5 | 1 year |

| CV517-2516

| 250*160 | 1000 | 9.5 | 1 year |

| CV517-3020

| 300*200 | 1200 | 9.5 | 1 year |

Cutting accuracy: ±0.1 mm

Repeatability: ±0.01 mm

Maximum cutting thickness: 7mm

Fabric fixing method: vacuum adsorption to ensure flatness

Tabletop wear resistance: it is recommended to replace the tabletop once a year.

Standard order: smart sample cutting software, smart cutting machine, computer, projector, brush function.

Optional: Inkjet marking function of the software, vibrating cutter head can be added.

Power supply 220V/380V 50Hz-60Hz 20A-40A

The SmartCut Fabric Sample Cutting Machine is on hot sale! Welcome to contact us for more details of the Smart Sample Cutting System.

And for the price of this Fabric Swatch Cutting Machine, you can click the What’s App right corner.

You must be logged in to post a review.

What is a Fabric Weight Cutter?

GSM machine, also known as fabric weight GSM, is mainly used in textile fabrics, leather, copper foil, glass fiber and other industries, used to measure the weight of product unit area. At present, some people call the fabric sampler cutter, some call the sampler cutter and the electronic balance together.

Why do you Need a Fabric Weight Circular Cutter?

In the process of fabric production, various tests are needed. In order to the consistency of the test standards and reduce the error of the test, we need deal with the test samples in a unified way by gsm fabric cutter. The GSM cutter and scale are used together, according to the fabric gsm cutter calculation, we can get the test samples suitable for us. The fabric punch and scale is a necessary testing instrument.

Instrument Operation

1 Lay the fabric to be cut flat on the GSM cutter pad, place the disc sampler on the fabric, pull out the locking device on the sampler, rotate about 90 degrees. Hold the outer cover in one hand, hold the handwheel in the other hand, and apply certain pressure, then rotate the handwheel clockwise (the angle is greater than 90 degrees) and cut the round sample.

2 When the sample cutter is used, lock the device and rotate to the position so that the blade cannot be exposed to avoid danger.

Notice

1 The blade edge of this instrument is sharp, do not put your hand on the bottom to avoid injury during use.

2 The sample should be cut on the GSM cutter pad, the instrument should be cleaned when not used and placed in the instrument box to avoid damage.

3 If the blade is not sharp after a period of time, it is necessary to replace the blade.

Test Result

What is GSM in fabric? After taking the sample, weighing it on an electronic balance with an accuracy of 0.01g. After reading, the weight displayed is multiplied by 100 to be the weight of the sample of 1m². For example, the weight of the sample read by the electronic balance is 3.57g. then, The weight of the sample of 1m²(100 GSM fabric) is 357g.

If you want to know more about GSM weight cutter machine price, or even more, please contact us.

[contact-form-7 id="16355" title="Inquiry"]

Reviews

There are no reviews yet.