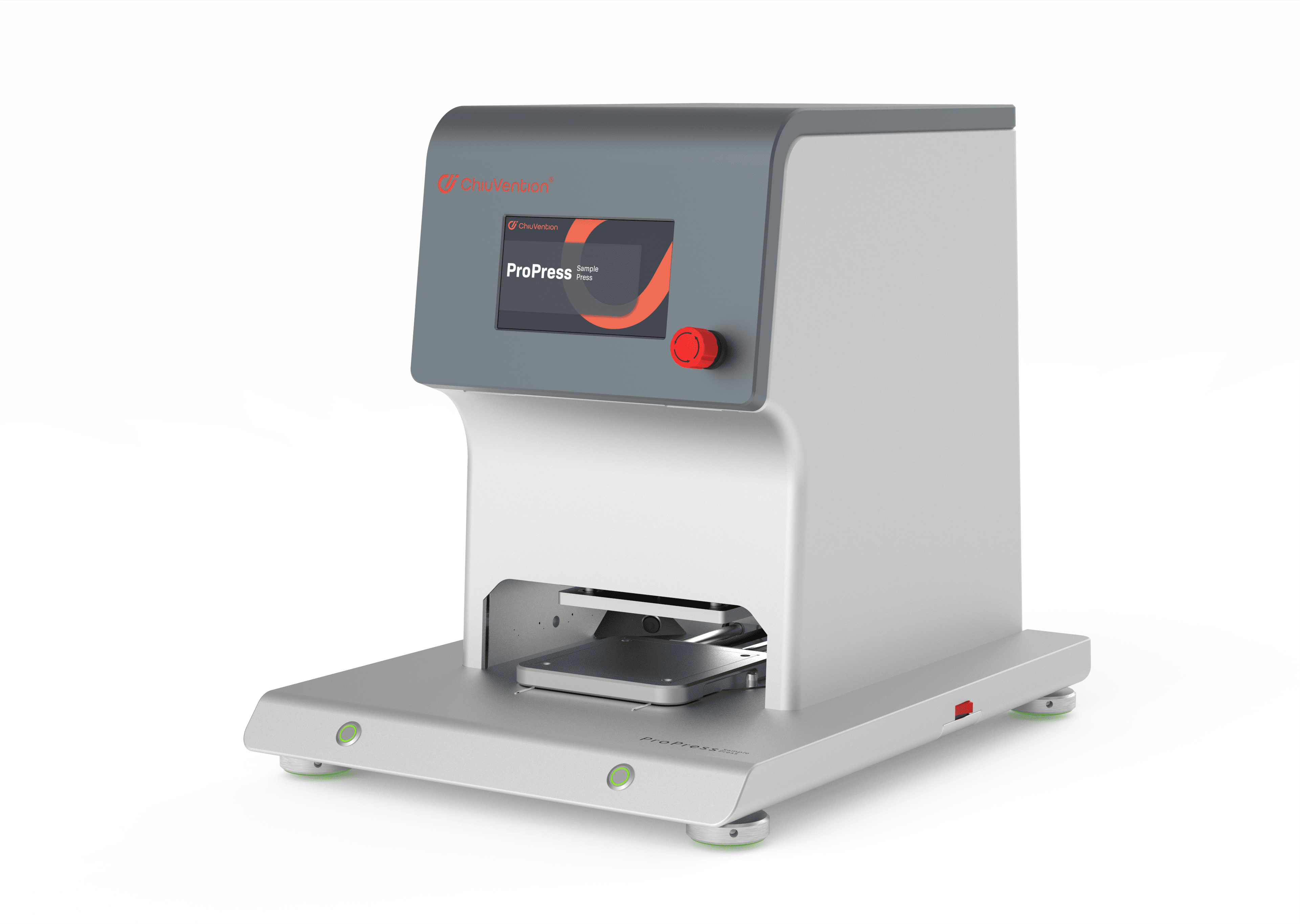

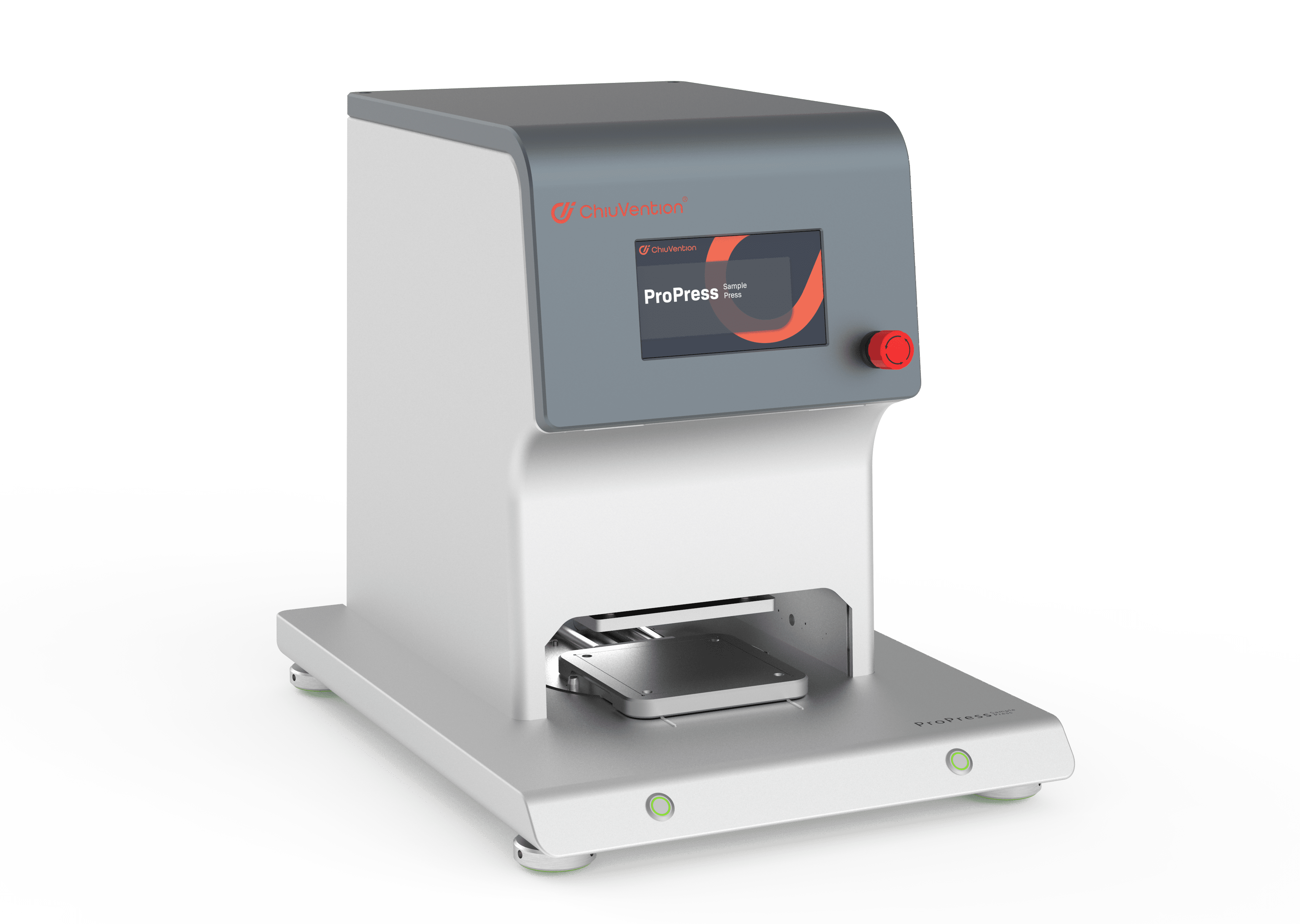

ProPress Sample Press | A new machine developed by the sister company ChiuVention.

The ProPress Fabric Sample Cutting Machine cuts the samples into small pieces (e.g. 3×3 mm) within 8 seconds automatically and it can also cut multiple layers of fabric in a single pass. This Sample Cutting Machine is servo-driven and runs without an air source and oil pressure. It can be placed on the table for its small size. ProPress fabric swatch cutter is applicable for formaldehyde, pH, and other tests of fabrics, yarns, leather, plastics, and other flexible materials.

By using the ProPress Fabric Sample Cutting Machine, the work efficiency of cutting samples increases by more than 80%, which is 6 times manual shearing. Besides, we also provide other types of fabric sample cutting machines.

Description

The working principle of the ProPress Sample Cutting Machine

Lay the sample flat on the plate, and press the button with both hands, then the plate will enter and the sample cutting machine automatically presses and cuts the samples. When the cutting is finished, the ProPress textile sample cutting machine automatically activates a strong air-cleaning system to blow away any fibers and debris left behind, ensuring that the samples are not mixed.

The operator can observe whether there is any fabric sample residue through the high-definition camera equipped with ProPress Sample Cutter from the operation screen, and can manually start the cleaning program again.

In addition, the ProPress fabric swatch cutter ensures your safety: start up with two hands, and the work area is equipped with a light barrier to prevent accidental injury. Applicable for various cutting sizes such as 3×3 mm, 5×5 mm,10×10 mm, or the dimensions can be customized.

More accurate sample preparation, for more reliable test results.

Traditional manual cutting of fabric samples can easily lead to large differences in sample shape and size, which can cause insufficient dissolution, thus affecting the reliability of the test; ProPress swatch cutter machine cuts samples by pressing, which is precise and fast, and the highly consistent samples make the fabric test results of formaldehyde, pH value, etc. more reliable.

Faster sample preparation, saving more than 80% of the time.

The ProPress Fabric Sample Cutting Machine presses samples in several seconds per operation, compared to at least 60 seconds for manual cutting, making it valuable for large-scale fabric testing labs that prepare large numbers of chemical test samples every day.

Ensures the pass rate of textile samples throughout the whole process.

The ProPress fabric swatch cutting machine is equipped with a self-cleaning system that blows air to clean all kinds of fiber debris generated during the cutting process, and a built-in high-definition camera (2 megapixel, 1920×1080 resolution) used for observing the cleaning and ensures that there is no mixing between samples.

The Specification of ProPress Sample Cutting Machine

Machine 1. CV.518.01 CV518 ProPress Sample Press

Press thickness 0.1mm*4mm

Press pressure 5T (adjustable force as 1T, 2T, 3T, 4T, 5T, to improve the service life of the cutter)

Power supply 220V 5A /110V 10A 50/60Hz

1200W

Net weight 100kg

Net size 600*450*530 mm (L*W*H)

Gross weight 126kg

Packing size 740*550*740 mm (L*W*H)

Standard accessories (mode and dimensions)

Matting 4.M.011 129 mm*129 mm*6 mm 6pcs

Die 2. Z.CV518.01 5 mm *5 mm(Press area 100mm*100mm) 1pc

Pallet 2. Z.CV518.03 160 mm*160 mm*16 mm 2pcs

Optional accessories (mode and dimensions)

Die 2. Z.CV518.02 3 mm *3 mm (Press area 80mm*80mm)

Hoover 7.XCQ.001 220V 1200W

Hoover 7.XCQ.002 110V 1200W

Other customized die dimensions limits: max. diameter 113 mm, min. diameter 4 mm.

Wear parts and consumables of Fabric Sample Cutting Machine

Matting 4.M.011 129 mm*129 mm*6 mm

(Forward and reverse sides are available)

Die 2. Z.CV518.01 5 mm *5mm

(Press surface 100mm*100mm or customized dimensions)

Installation conditions of Fabric Sample Cutting Machine

Equipped with a socket 220V or 110V, compressed air (or not), work surface area of not less than 700mmx1000mm

Applicable Tests and Standards of Sample Cutting Machine

pH test ISO 3071 GB/T 7573

Formaldehyde ISO 14184.1 GB/T 2912.1

Heavy metal GB/T 17593.1/2/3

Azo FZ/T 01133 GB/T 17592

You must be logged in to post a review.

What is a Fabric Weight Cutter?

GSM machine, also known as fabric weight GSM, is mainly used in textile fabrics, leather, copper foil, glass fiber and other industries, used to measure the weight of product unit area. At present, some people call the fabric sampler cutter, some call the sampler cutter and the electronic balance together.

Why do you Need a Fabric Weight Circular Cutter?

In the process of fabric production, various tests are needed. In order to the consistency of the test standards and reduce the error of the test, we need deal with the test samples in a unified way by gsm fabric cutter. The GSM cutter and scale are used together, according to the fabric gsm cutter calculation, we can get the test samples suitable for us. The fabric punch and scale is a necessary testing instrument.

Instrument Operation

1 Lay the fabric to be cut flat on the GSM cutter pad, place the disc sampler on the fabric, pull out the locking device on the sampler, rotate about 90 degrees. Hold the outer cover in one hand, hold the handwheel in the other hand, and apply certain pressure, then rotate the handwheel clockwise (the angle is greater than 90 degrees) and cut the round sample.

2 When the sample cutter is used, lock the device and rotate to the position so that the blade cannot be exposed to avoid danger.

Notice

1 The blade edge of this instrument is sharp, do not put your hand on the bottom to avoid injury during use.

2 The sample should be cut on the GSM cutter pad, the instrument should be cleaned when not used and placed in the instrument box to avoid damage.

3 If the blade is not sharp after a period of time, it is necessary to replace the blade.

Test Result

What is GSM in fabric? After taking the sample, weighing it on an electronic balance with an accuracy of 0.01g. After reading, the weight displayed is multiplied by 100 to be the weight of the sample of 1m². For example, the weight of the sample read by the electronic balance is 3.57g. then, The weight of the sample of 1m²(100 GSM fabric) is 357g.

If you want to know more about GSM weight cutter machine price, or even more, please contact us.

[contact-form-7 id="16355" title="Inquiry"]

Reviews

There are no reviews yet.