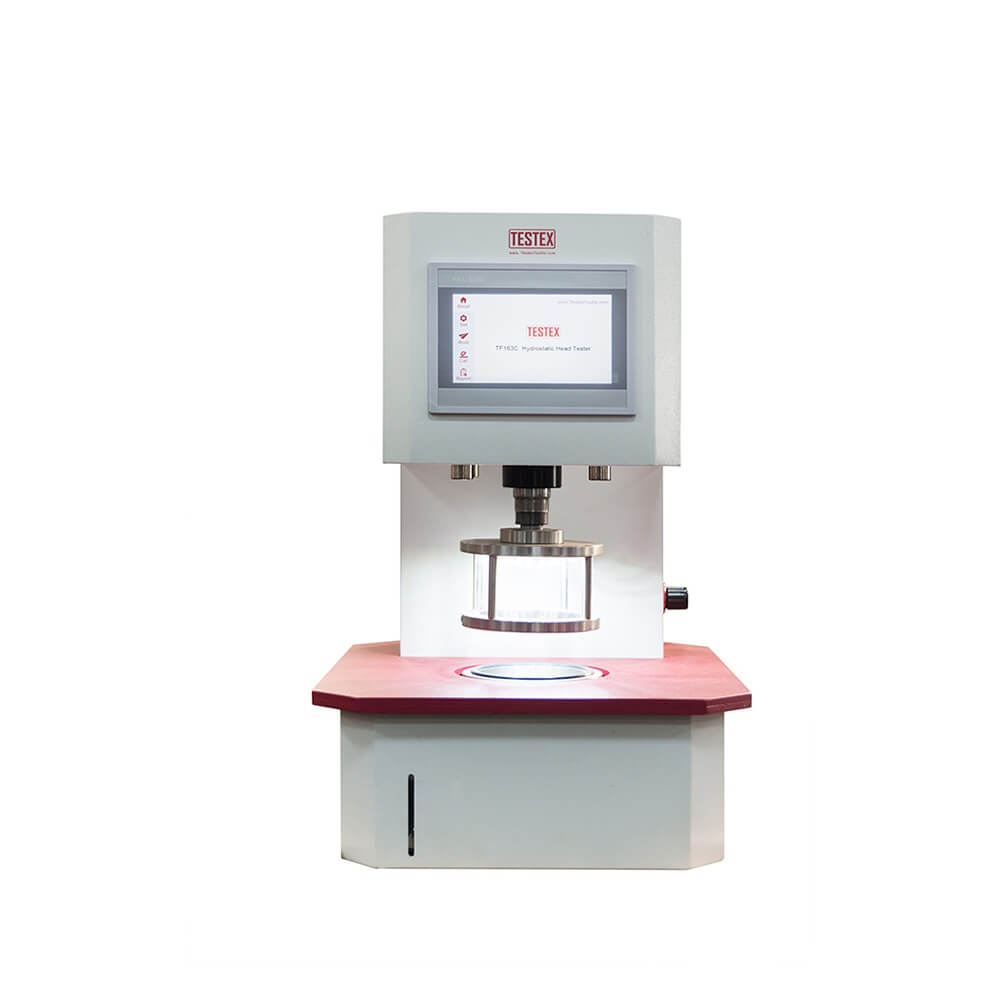

Hydrostatic Head Tester

Hydrostatic Head Tester TF163C or hydrostatic pressure testing machine is used to measure the resistance of a fabric to the penetration of water under hydrostatic pressure. It is one of the hydro-testing machines, widely applied for determining the resistance of fabrics (canvas, coated fabrics, cover cloth, rainproof clothing fabrics, and geotextile materials) and films to water penetration under pressure. Hydrostatic Head Tester TF163C complies with testing standards like AATCC127, ATSC127-2008, EN 20811, ISO 811, etc. Please contact us for the Hydrostatic head test(water penetration test) procedure,and get the hydrostatic head tester price.Our hydrostatic tester for sale.

Description

Application

Hydrostatic Head Tester TF163C is also named Hydrostatic Pressure Testing Machine TF163C. It can measure the water penetration resistance of fabrics under hydrostatic pressure by clamping the specimen on a standard test area. The hydrostatic test can include those kinds of fabrics, such as canvas, coated fabrics, cover cloth, rainproof clothing fabrics, geotextile materials, and films to water penetration under pressure while firmly clamped in the test rig of standard area. When you have a hydrostatic pressure testing machine, you can do a hydrostatic head test easily.

You can also learn more about hydrostatic head testing methods.

Features

Accurate testing

Test results are highly consistent with international third-party testing institutions and receive positive feedback from customers in over 60 countries.

Servo motor control, stable operation, and longer life

Closed loop control with servo motor-driven piston for a unique water pressure rise rate balancing system. In addition, the booster system has dynamic feedback adjustments to prevent overload.

Multiple testing methods, more practical

Different test methods can be selected and test times and variable boost rates can be set and saved. There are three test methods, i.e. boost mode, constant voltage mode, and constant voltage timing mode, to meet various needs. By this method, you can make a hydrohead test.

Rapidly produce test results and output reports

Equipped with LED lights for easy observation of the testing process; real-time test results are displayed on the large color touch screen; test results can be formed into reports on the software and printed out directly.

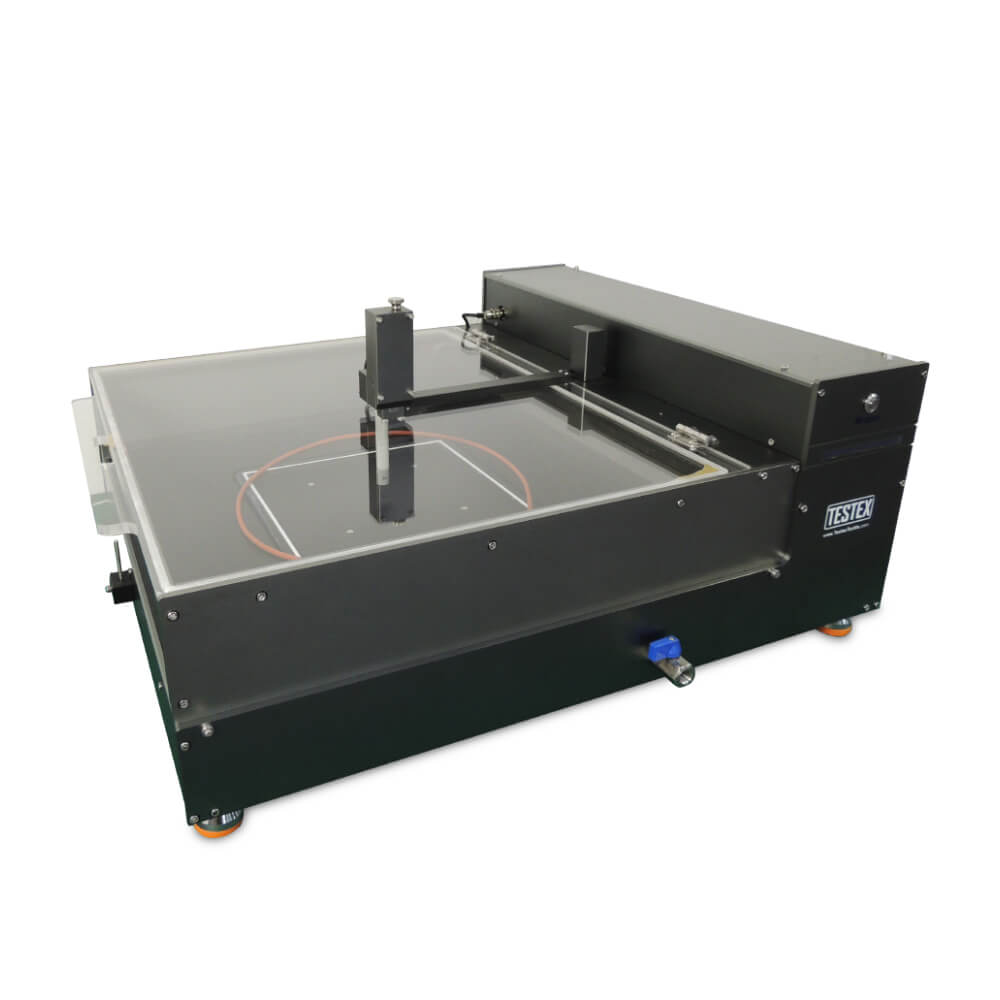

Specification

- Automatic fixture with clamping force: 5KN

- Standard test head: 100cm²

- Units: Pa, kPa, mmHg, cm water column

- Pressure range: 0 ~ 200kPa (20m water column)

- 0 ~ 500kPa (50m water column)

- 0 ~ 1000kPa (100m water column)

- Water pressure rise speed: 1 ~ 60 kPa / min step-less variable speed adjustable

Power

| 220 V | 50 Hz | 3 A | 500 W |

Dimensions

| Length: 500 mm | Width: 430 mm | Height: 700 mm |

Weight

95 kg

Standard

AATCC 127 Option 2, ISO 811, GB/T 4744, GB/T 40910, JIS L1092

Optional standards

ISO 9073-16, EN1734, ISO 1420, AATCC 208,IS 7016(Part 7), NWSP 080.6.RO(15),GB/T 24218.16, FZ/T 01004.

Know More about Hydrostatic Head Tester

Definition of hydrostatic pressure

Hydrostatic pressure refers to the resistance encountered when water passes through the fabric. The fabric is subjected to a continuous rise in water pressure until water beads up on the back of the fabric under standard atmospheric pressure. At this point, the measured water pressure value is the hydrostatic pressure. The greater the hydrostatic pressure that the fabric can withstand, the better the waterproofness or resistance to seepage.

Hydrostatic pressure units

The hydrostatic pressure can be expressed in N/㎡, Kpa, and water column height m. And the conversion unit is 1m water column height equals 9.82Kpa.

Hydrostatic head rating

Hydrostatic Head, given in millimeters. It’s a measure of how waterproof a fabric is, based on the water pressure it can withstand – the higher the number, the more waterproof the fabric. Contact us to acquire more detailed rating parameters about this hydro tester.

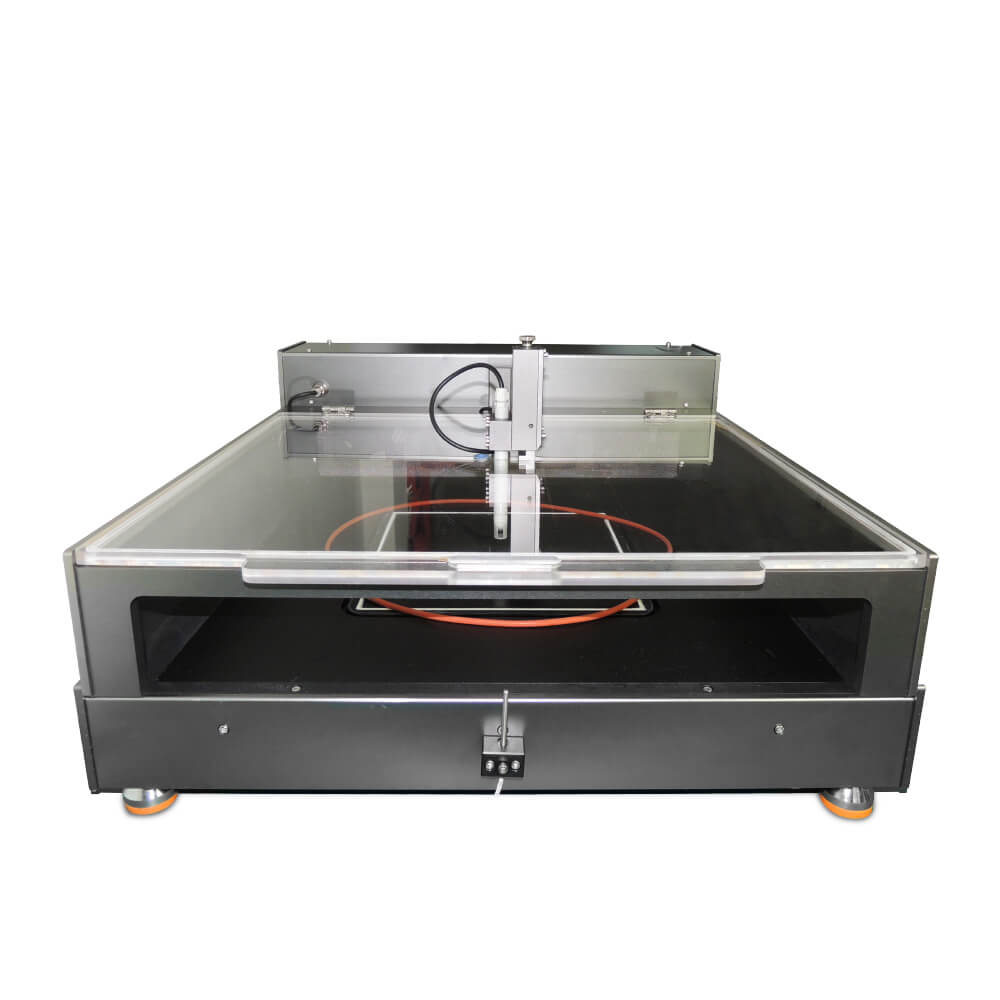

Precaution and Maintenance

1 Before the first operation, the operator must read the Operation Manual carefully and receive special technical training.

2 Sweep the upper chuck lightly before placing the specimen to avoid affecting the test results.

3 The default value of the cylinder is 0.5MPa (can be adjusted according to the characteristics of the specimen). The maximum error range should not exceed plus or minus 0.2MPa.

4 The inlet pressure should be less than 0.8MPa but the maximum pressure should not exceed 1MPa.

5 Turn off the power and then remove the plug from the power outlet after each test.

6 Emergency stop and restart the instrument in case of malfunction.

7 In order to ensure the normal operation of the machine, the user must regularly check the water level of the test tank. Meanwhile, drain the water out if the machine will keep idle for a long time. You, therefore, need to turn on the drain switch (horizontal direction to the outlet pipe) and by all means, avoid wetting the electrical equipment. After completing the drainage, close the drainage switch (vertically to the outlet pipe) and check that the drainage switch and the pipe mouth must not fall off.

8 Keep the touch screen away from sharp hard objects.

9 No strong electromagnetic interference in the surroundings.

Why choose TESTEX Hydrostatic Head Tester TF163C

Strictly meet standards

All data for the hydro testing machine meet the standard parameters, for example, AATCC 127 and ISO 811.

Consistency with international third-party laboratories:

The test data are comparable to the test results obtained by well-known international third-party laboratories. You can feel free to use our hydrostatic pressure tester for test experiments.

High reproducibility:

Whether is the same set of samples, or different machines of the same model, after multiple tests, the results are consistent.

Longer service life:

TESTEX makes prototypes and then subjects them to rigorous reliability testing in a variety of environments to ensure achieve the expected service life.

User-friendly transparent warranty policy

Textile testing machines, 14 months free warranty (12 months normal warranty time + 2 months shipping time). Besides, all spare parts, have 3 months free warranty.

We provide full life-cycle support for hydrostatic head tester TF163. So feel free to contact our service team with any questions you may have. And get the hydrostatic pressure testing standards from us.

Welcome to TESTEX – a professional textile testing instrument supplier – Hydrostatic Head Tester TF163 is on sale, contact us to get a detailed price quote.

3 reviews for Hydrostatic Head Tester

You must be logged in to post a review.

What is the hydrostatic head tester:

The definition of hydrostatic head is the pressure of homogeneous fluid act on an object, which can explain that each part of an object is forced uniformly. The object will shrink its volume when the hydrostatic pressure is enhanced but will not change.

Hydrostatic head test procedure:

- Turn on the power.

- Turn on the air pump and adjust the air pressure governor to ensure that air pressure in a reasonable range.

- Pouring water into the water tank until it reaches the highest water level.

- Setting and saving the parameter on the setting page according to the standard, go to the test page.

- Place the sample on the clamp to fix it, and then put the sample into

Attention: The pressure transducer should be zeroed or cleared. Otherwise, the test result might be inaccurate.

- Start the test and observe the sample.

- he third water droplet has appeared on the surface a we should stop the test and record the data.

- After that, we need to release the sample and change another one for the next test.

- Draining the water after all the test is finished, and turn the power off.

A: Hydrostatic pressure refers to the water permeability of fabrics under certain water pressure. It is suitable for all kinds of fabrics, including those treated with waterproofing.ydrostatic pressure method is used to measure the waterproofing offabrichere are static pressure methodand dynamic pressure method. Static pressure is used for water-conducting fabrics, and dynamic pressure is used for coated or compact fabrics.

A: Yes, it is.

Mildred House –

great shipment! awesome product!

Barry Noel –

Excellent! I’m satisfied with the result, good price, good package and good service!

testextextile –

You are a nice man too.

Walker George –

Everything goes well,will come and buy again if the hydrostatic head tester good in use.