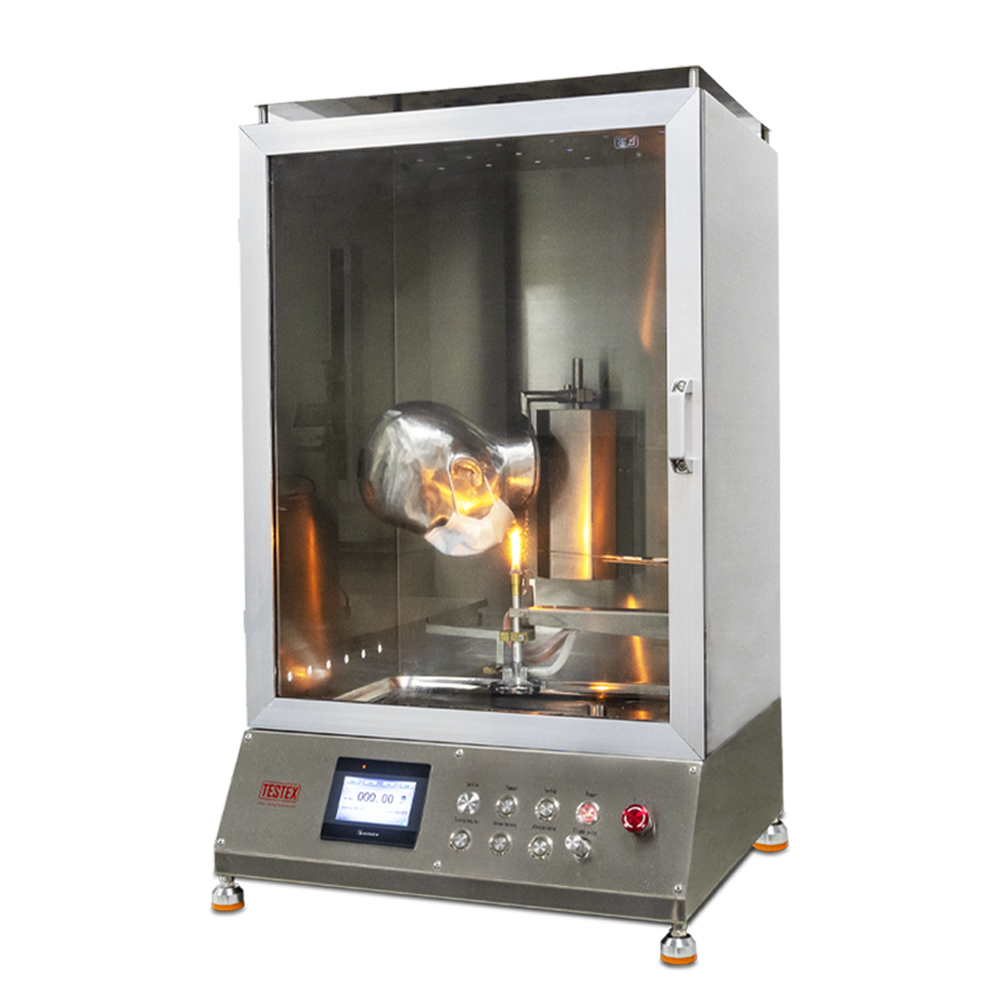

Medical Masks Flammability Tester TF361

Medical Masks Flammability Tester is used to test the flammability of medical masks, to ensure the safety of masks to wear in. Medical Masks Flammability test Chamber complies with EN 149, GB 2626, GB 19083.

Description

Application

Medical Masks Flammability Tester is used to test the flammability of medical masks, to ensure the safety of masks to wear in. Medical Masks Flammability test Chamber complies with EN 149, GB 2626, GB 19083.

The burner ignites the specimen automatically, and ignition time is programmable; after-flame time and afterglow time are timed automatically and shown on the display. The user-friendly design of the control panel, Touch screen is equipped to make the operation conveniently, the test results are displayed on the screen after the vertical flammability test.

Comprises a draft-free stainless steel flammability chamber with an observation window for easy test viewing. human-head-shaped Specimen masks holders, burner, and associated hardware are dependent on the test standard and must be specified.

Specifications

- System and Display Programmable PLC and touch screen controls

- Time Display and accuracy 0-999.9s, 0.1s

- Burner Complied with ISO 6941

- Burner to specimen distance 20 mm

- Moving Rotating at a linear speed of 60mm/s

- Power 220 /110 V 50/60 Hz

- Weight 65 kg

- Dimensions 650 x 580 x 1120 mm (L x W x H)

Standards

- EN 149, GB 2626, GB 19083

You must be logged in to post a review.

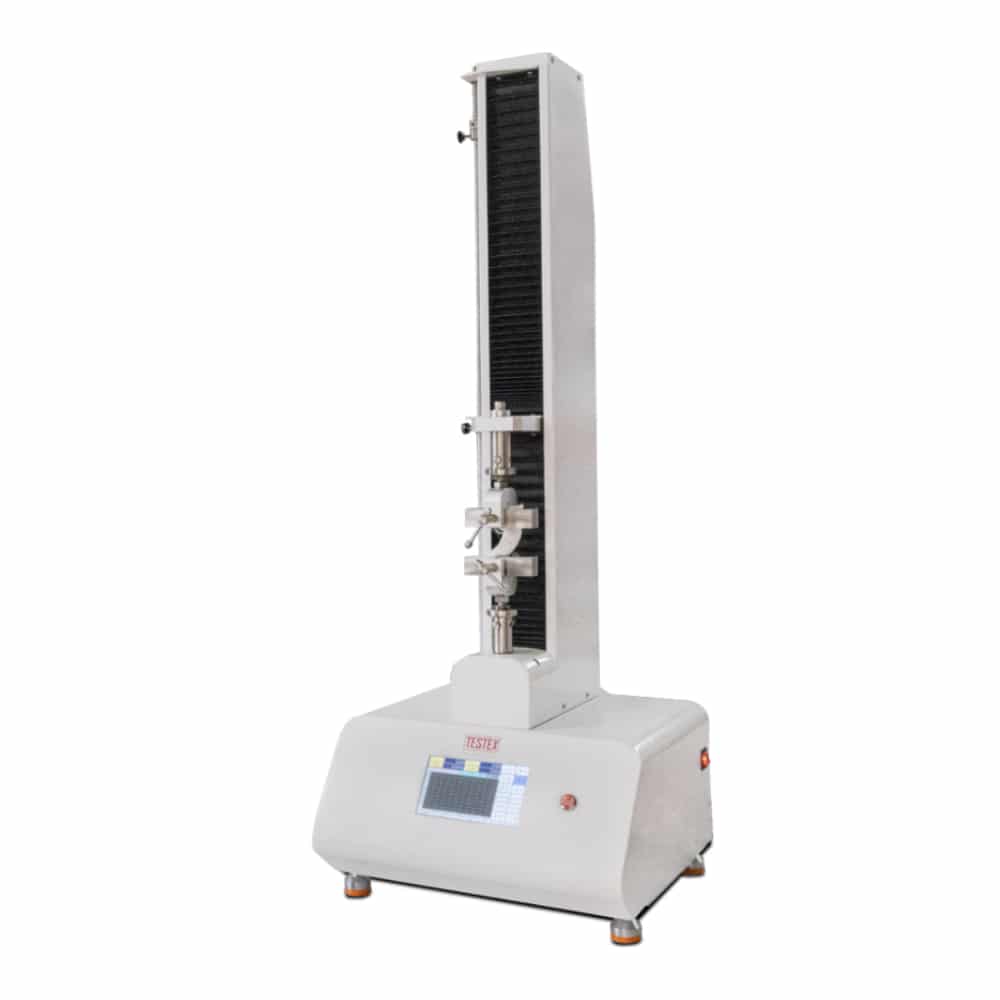

What is the Vertical Flammability Chamber?

The vertical flammability tester is used to test the combustion performance of children's pajamas or decorative fabrics. Sealed stainless steel combustor, an observation window and a standard burner, which can test flame spread speed accurately. With different sample clip and accessory test package to meet different test standards. Control the testing process easily through an automatic gas control system. Here take the ASTM D6413 standard as an example to introduce the vertical flammability test of the fabric.

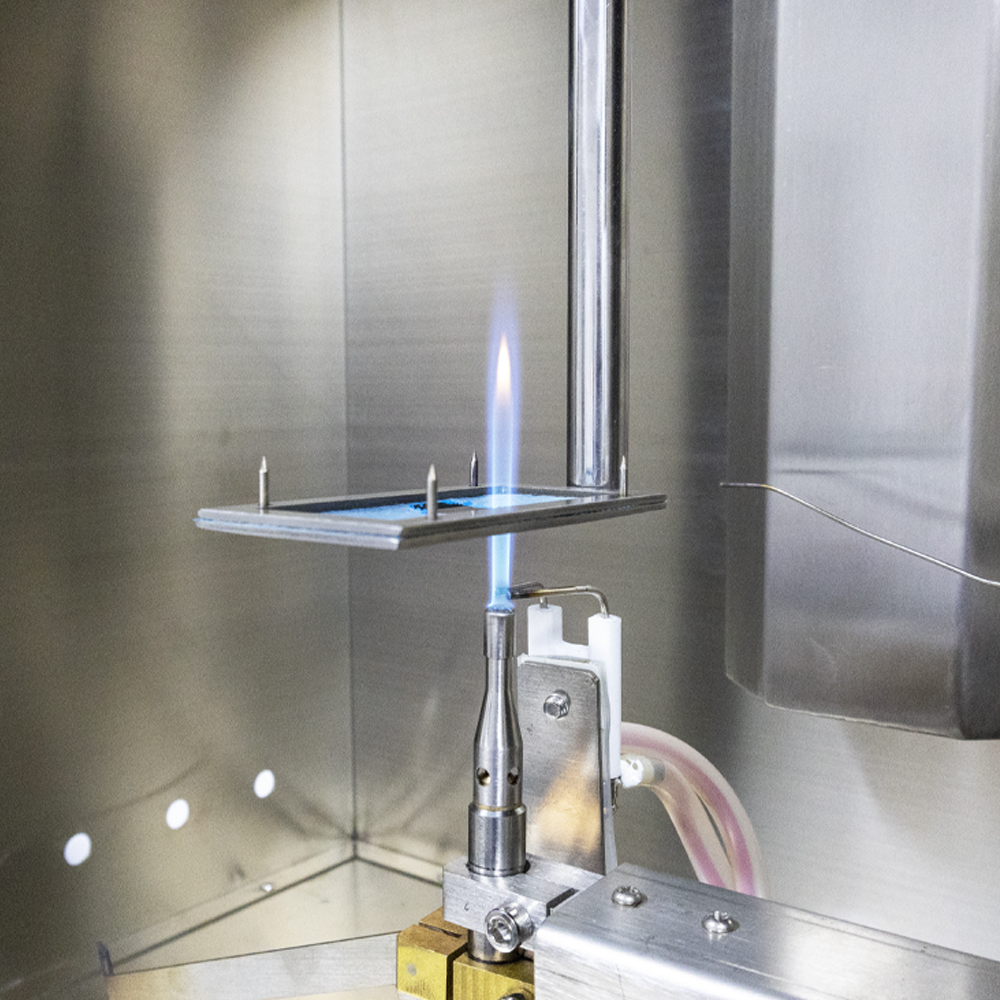

Regulating Instrument

Adjust the gas pressure to 17.2±1.7KPa and ignite the flame, adjust the flame height to 3mm, and ensure that the shape of the flame will not change in 12s. Close the vent and open the solenoid valve to ensure that the flame height reaches 38mm. Adjust the burner position so that the lower edge of the sample clip is in the middle of 19mm at the top of the burner. Adjust the timer to ensure that the ignite time of the sample is 12±0.2s.

Sample Preparation

Cut 5 samples along the longitudinal and transverse directions, the size is 76mm * 300mm, and ensure that the sample is flat. Then adjust the humidity of the samples as required and store them in the dryer.

Test Program

1 Remove the sample from the dryer, install the sample and set it on fire in 4 minutes.

2 Fix the sample with the sample clip, then put it into the test box, and adjust the burner so that the center point of the bottom edge of the sample is located at the position of 19mm above the burner.

3 Open the igniter and ignite the sample for 12±0.2s. Observe the melting and dropping of the sample during combustion, and record the observation results.

4 After removing the fire source, record the time of continuous combustion and the flameless combustion time of the material. Don't extinguish Mars because it affects the carbonation length.

5 Remove the sample clip from the test box and open the ventilation cabinet to remove the smoke from the test box.

6 Measure the carbonation length along the intact edge of the sample.

What should be Paying Attention to in Vertical Burning Testing?

1 Whether the sample and the sample rack are accurately installed is an important factor that affects the vertical burning test.

2 When cutting the sample, you should try to cut flat and wrinkle-free samples. The upper and lower ends of the sample should be trimmed flush, the size should be as accurate as possible.

3 When placing the specimen on the specimen holder, care should be taken so that the lower end of the specimen is flush with the lower end of the specimen holder to ensure accurate measurement of the length during the vertical burning test.

4 Suspension of the sample holder should be hanging vertically above the igniter, not tilted. The center of the sample should be in the flame.

[contact-form-7 id="16355" title="Inquiry"]

Reviews

There are no reviews yet.