InnoFlex Bally Flexing Tester | A smart instrument developed by the sister company ChiuVention.

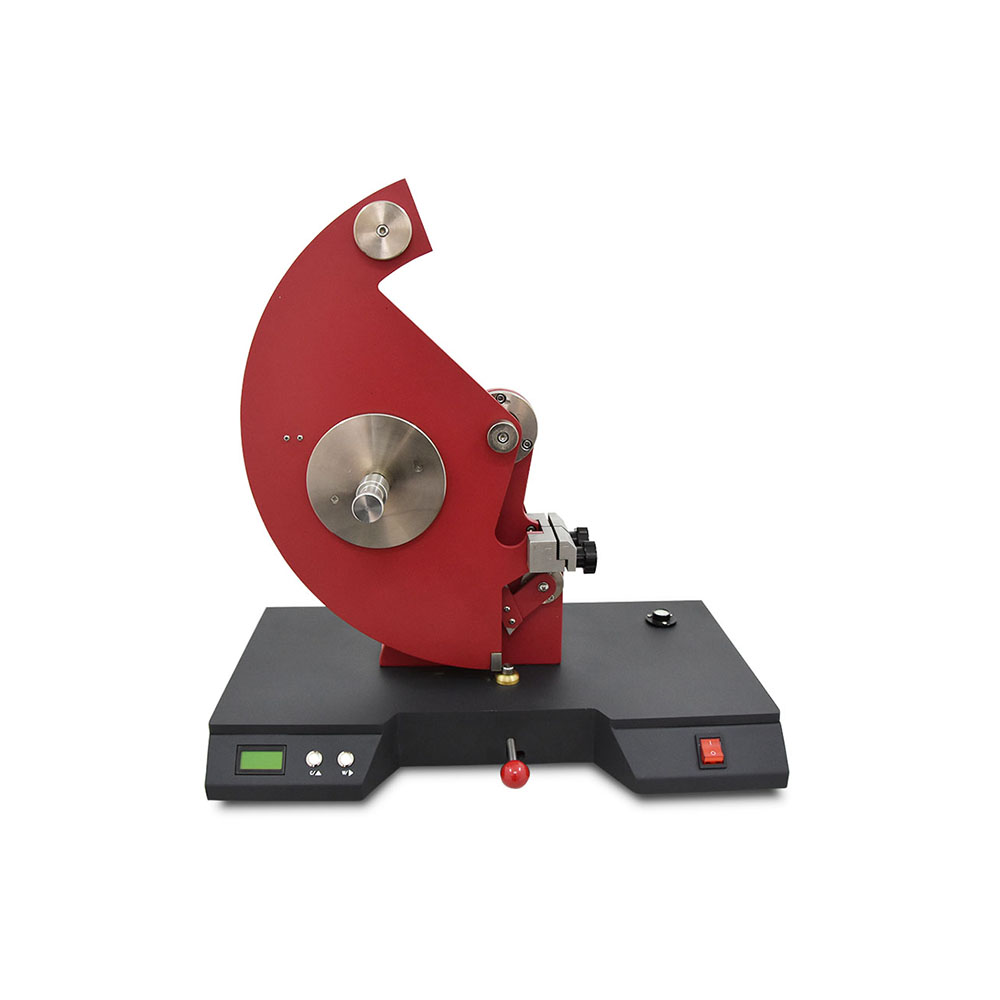

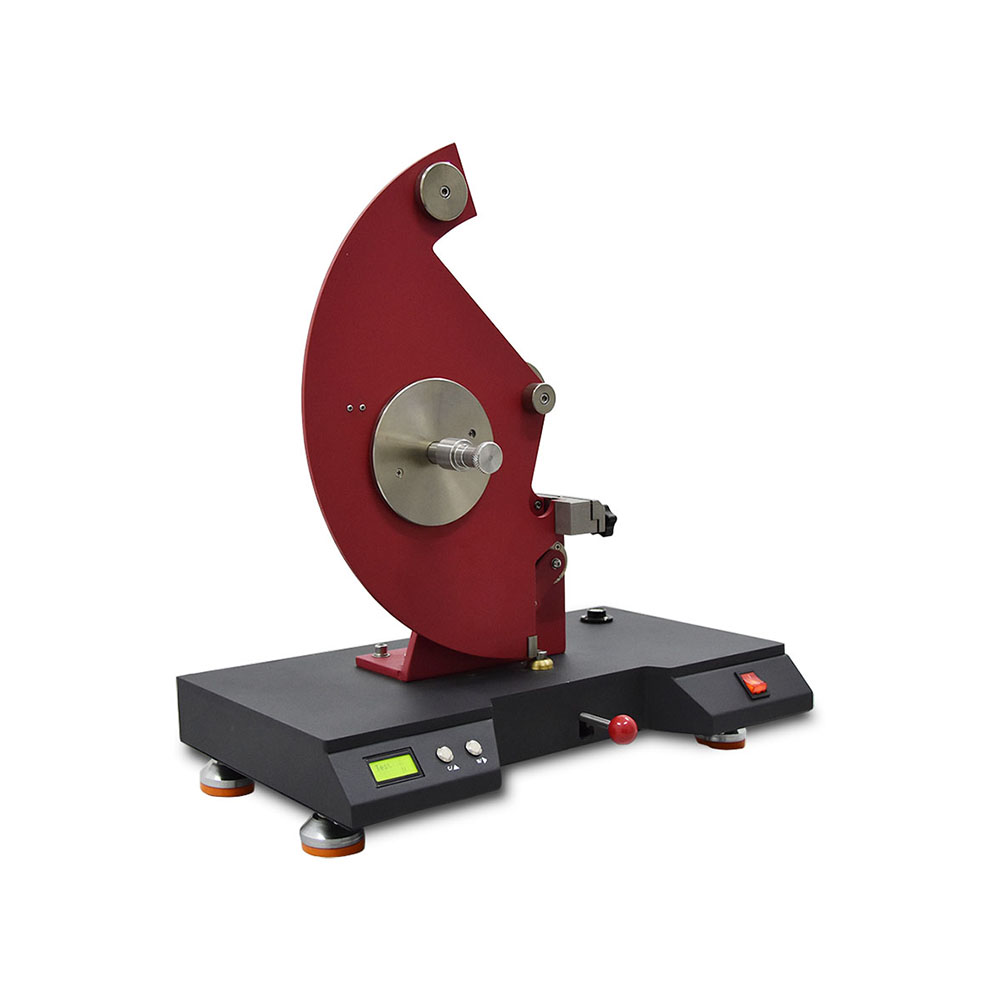

The InnoFlex Bally Flexing Tester is also known as the InnoFlex Flexometer. It is used to test how well leather, cloth, and other materials resist flexing. One side of the sample is the inner side, and the other side is the outer side. The InnoFlex folding endurance tester bends the sample back and forth. This bending damages it. Or, it will bend it a certain number of times. This shows the degree of damage and determines the sample’s flexing strength.

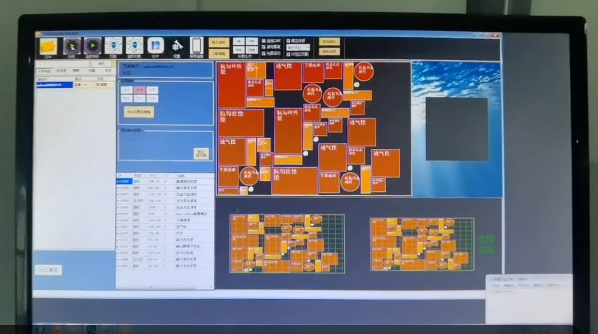

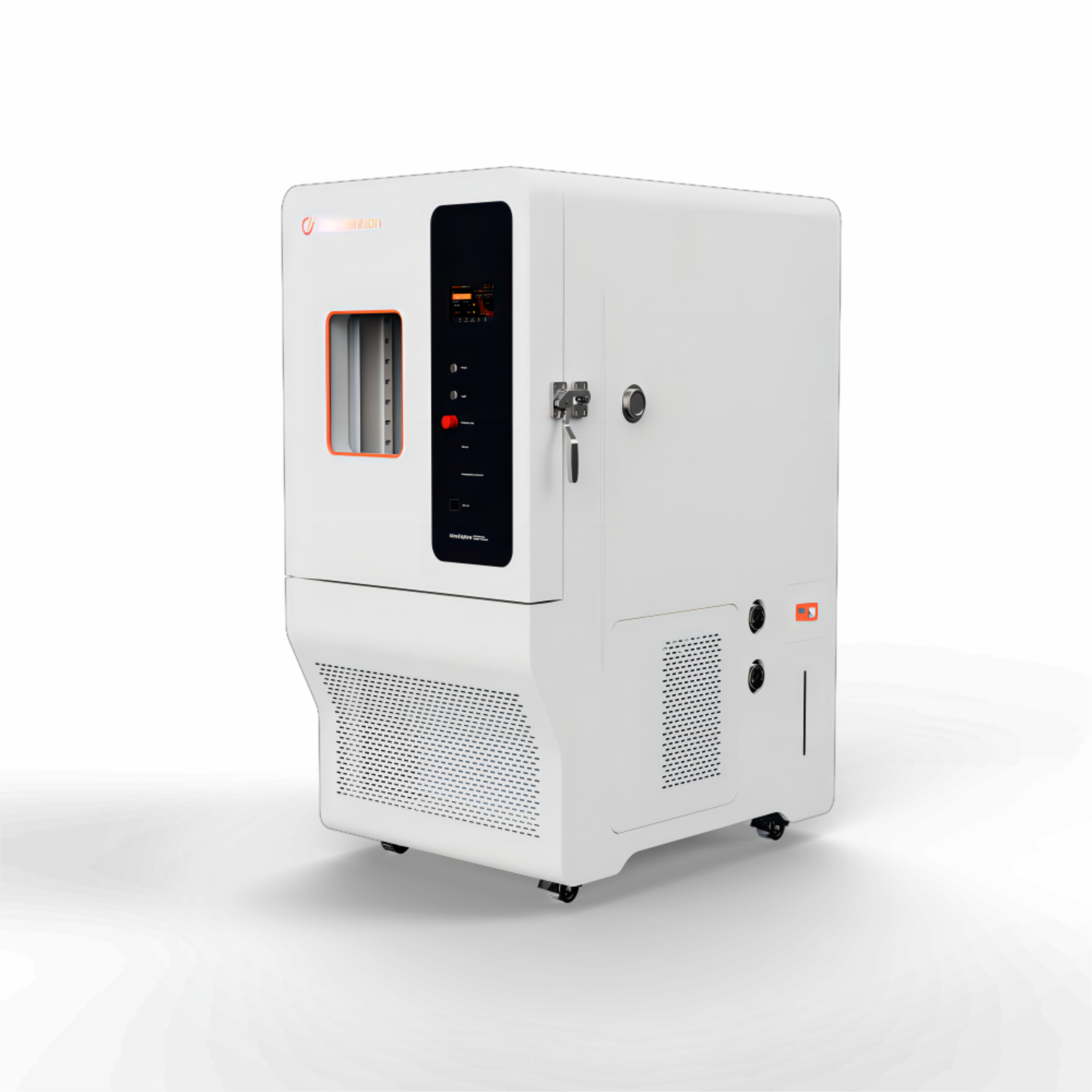

The InnoFlex Bally Flexing Tester has advanced servo motors for precise positioning. It has a stable testing process. This allows for more accurate and reliable tests. It is a smart instrument. It can connect to the SmarTexLab app on your smartphone via WIFI. This lets you remotely set the parameters and watch the testing process. It greatly improves work efficiency. With a noise level of only 60 dB, it is user-friendly and durable. Suitable for a wide range of testing standards, such as ISO 5402-1:2017, ISO 32100:2018, and ISO 20344-2011, SATRA TM 55.

Description

More accurate and reliable tests

Microcomputer program control and advanced servo motor bring accurate positioning. The flexometer can return to its start position automatically. It stays stable during the test. This stability helps to make tests more accurate and reliable.

Smart flexometer

Users can connect it to the SmarTexLab app on smartphones through Wi-Fi. This lets them set parameters, watch tests, get alerts, and share results in real time.

Efficient and durable.

You can select 12 workstations and choose either single-station or multi-station mode. You can count the running times of each mode, so you can test a variety of samples at the same time. The NSK bearings are from Japan. The machine is made of precision mold-casting stainless steel. It has a scratch-resistant appearance and lasts longer.

More user-friendly

The actual noise is only 60dB, much lower than other flexomoter in the market. The interface is ergonomic, making it comfortable to use. If a power failure occurs, running data is saved.

The Specification of InnoFlex Bally Flexing Tester

Testing station: 12 stations

Testing speed: 100r/min

Working stroke: swing angle 22.5°±0.5°

Test times: 0~9,999,999 (adjustable)

Maximum clamping distance:

The maximum folding thickness of the test sample is 7mm

Upper and lower spacing:

The spacing between the upper and lower clamps is 25mm

Standard accessories

Cutter die: 70X45mm

Standards

ISO 5402-1:2017

ISO 32100:2018

ISO 20344-2011

Optional standards

SATRA TM 55

What is a Bally flexing tester?

Bally Flexing Tester, also known as flexometer, leather bending tester. It is an international instrument used to evaluate the bending resistance of various light leather and its surface modifiers under continuous bending.

The Flexometer applies to all flexible materials, in particular leathers, artificial leather below a thickness of 3.0mm, and other coated fabrics, sheet materials, etc. In addition, TESTEX also sells De Mattia flexing tester, Schildknecht flexing tester, and Crumple flexing tester, so you can have more choices.

How does the Bally Flexing Tester work?

How to use a bally flexing tester for a pleximeter test? The flexometer uses one side of the specimen as the internal test and the other side as the outer side. Then clamp the specimen in the upper movable clip. In contrast, the surface to be tested faces outwards and is clamped in the lower retaining clip.

Record the bending times, or after bending a certain number of times, and observe the degree of damage. observe the surface of the specimen with a magnifier, and record the degree of damage to test the flexure strength of the specimen.

Flexing test procedure

1 Clamp the specimen in the upper and lower jigs as required by the standard

2 Preset flexing number or flexing time

3 Start of flexing test

4 Observe the degree of damage to the specimen

5 Calculate the number of flexing

Note during the flexing test

When re-clamping the specimen, keep it as close to the original condition as possible.

When stopped, the specimen should be left in its natural relaxed state.

A good light source and magnifying glass should be available to observe the extent of specimen breakage.

Common conditions of damage to specimens, from mild to severe

Discoloration of the coating, but no damage.

Cracking of the coating surface and then loss of adhesion to the leather

The coating becomes a powder and is accompanied by partial peeling.

Granular cracking of the leather.

The continued destruction of the leather fibers and eventual breakage.

6 reviews for InnoFlex Bally Flexing Tester | A smart instrument developed by the sister company ChiuVention.

You must be logged in to post a review.

A: Yes, it is.

Andre J –

This desktop bally flexing tester, easy to put the sample in, low noise

Michell Pepys –

I purchased this item based on the positive reviews. The product is really good, but the shipping time need to be shortened.

Jeff Archibald –

I am pleased with this unit.Thanks manufacturer!

Clarence Boyle –

I’m satisfied with your professional solution.

Nora Richards –

The machine is good.Thanks for your excellent service!

Martin –

Excellent. very well packaged goods.