Downproof Tester TF134

Downproof Tester TF134, to determine the down-proof capability of fabric used for downgraded, quilts, etc, which are full of down, feather, and fibers. The down-proof tester evaluates the overall down-proof performance of garments by testing the number of down, feathers, and filaments that burrow or fall out of samples such as down jackets and quilts.

Downproof Tester TF134 complies with EN 12132-1, GB/T 12705.1, etc.

Description

Application of Downproof Tester TF134

What does the fabric down-proof mean?

Fabric down-proof means the performance of textiles (mainly down jackets and quilts) that prevent down or feathers from burrowing through the yarn seams. The fabric wrapped in down must have down-proof or anti-drilling properties.

Down is a snowflake-like object with a soft down core that will not drill out at will when wrapped in a fabric of standard density. The most likely cause of the down jacket drill down is the external wrapping of the fabric density being too low, or seam processing improperly caused by the down leakage.

About the down-proof tester, there are two most common types, one can be used for friction testing and the other for impact testing. Also Known as Tumble Method testing.

Test Method of TF134:Take an agreed-size specimen from the fabric to be tested to sew a pocket at the specified size, fill it with a certain weight of down, feathers, or a mixture of both, then sew the fabric up to be a testing bag. Clamp both sides of the bag in the holder. After the test determines the down-proof ability of the fabric by calculating the number of down and feathers through the fabric.

Features of Downproof Tester TF134

The number of friction and running speeds can be set digitally, with accurate counting. Industrial color touch screen display and control, friendly human-machine interface, easy to use, more convenient operation.

Adopt a DC servo motor, smooth running, and low noise.

Equipped with an organic glass shield, you can clearly see the testing process while ensuring safety.

Simple and beautiful modeling, small in size, space-saving, and more convenient to use.

Sold to 42 countries around the world, reliable quality, reputation testimony.

Specifications of Downproof Tester TF134

- LCD displays and control

- Fixture space 44 ± 1 mm

- Eccentricity 25 ± 0.5mm

- Speed 0~200 r / min (Adjustable)

- Sample size 140 x 420 mm

- Cushion size 120 x 170 mm

- Test times 2700, settable

- Counter 0 to 99,999 times

- LED display

Weight

| 40 kg |

Power

| 220/110 V | 50/60 Hz |

Dimensions

| Length: 510 mm | Width: 380 mm | Height: 340 mm |

Standards

| EN 12132-1 | GB/T 12705.1 |

Principle

Make a sample bag of a certain size, and fill it with a certain amount of down and feather fillers. Install the sample bag on the instrument to simulate the effects of extrusion, rubbing, and friction. Finally, they evaluate the down-proof properties of the fabric by calculating the number of down or feather particles that have passed or protruded from the primary tick fabric.

Testing Steps

1 Prepare the specimen bag according to the standard requirements and fill it with down feathers.

The bag shall consist of low-density polyethylene (PE-LD), thickness (25±1) µm, and be without a pleat. The bag shall have the following inner dimensions.

- Width: (150±10) mm

- Length: (240±10) mm

2 Conditioning of the test specimen under the specified atmospheric according to EN 20139.

3 Before starting the test, clean any feathers down left outside the sample bag or on the apparatus to avoid affecting the test results.

4 Attach the specimen bag to the test apparatus, start the apparatus and begin the rubbing test.

5 Test the down-proof properties of the sample bag in both directions.

Welcome to TESTEX – a professional textile testing instrument supplier – Downproof Tester is on sale, contact us to get a detailed price quote.

5 reviews for Downproof Tester TF134

You must be logged in to post a review.

The Definition of Fabric Down-proof Capability

The fabric down-proof tester is used to detect the ability of down or fiber to drill through cold clothing, bedding, and so on. Down-proof property refers to the fabric's ability to prevent down or feather from leaking through the yarn crevice, expressed by the drill number under specified conditions.

Test Principle

At present, there are three testing methods of fabric down-proof properties at home and abroad: the rotating box method, the friction method, and the impact method. A cushion of specified dimensions is made from the fabric to be tested for its down-proof properties and is filled with a given amount of feather and down materials or its mixtures. The cushion is mounted in an apparatus and undergoes a specified number of rubbings. The number of down or feather particles that have passed or protruded from the primary tick fabric is counted.

Friction Method

The friction method is to make the sample into a sample bag of a certain size and put in a certain quality feather-down filler. Install the sample in the plastic bag of the instrument, and make the feather down drill out of the fabric surface through the functions of extrusion, kneading, friction, etc. Evaluate the fabric's down-proof properties by calculating the number of drill roots.

Test Step

1 Cut the sample as required. Adjust the sample in an atmosphere according to EN 20139, and measure the temperature and relative humidity according to EN 20187.

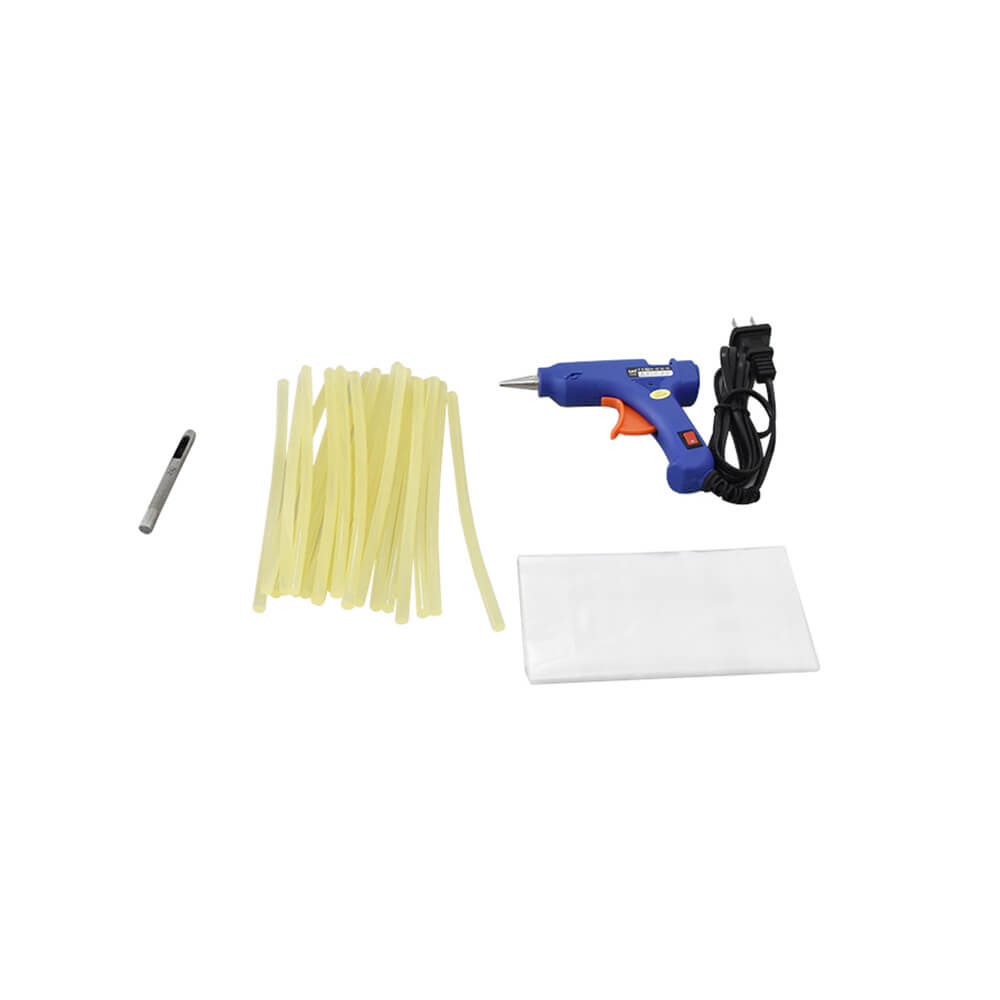

2 Before testing, the cushion is placed in a plastic bag. This permits the total collection of any particles that penetrate completely through the cushion's primary tick fabric.

3 The plastic bag containing the test cushion is then fastened in the clamps of the test apparatus. The cushion's flaps are placed in the clamps and the cushion is folded between these clamps.

4 The counter is set for 2700 revolutions. The apparatus is started, and after 2700 revolutions (approximately 20 min) it is automatically stopped by the counter.

5 Afterward, the cushion is taken out of the plastic bag. If the number of filling particles in the plastic bag plus the number of filling particles protruding from the cushion is greater than 50, counting shall be stopped.

As a professional supplier of textile instruments, we are committed to continually improving the user experience, TESTEX Textile Testing Equipment is a reliable choice for testing textile quality.

Notes in operation

1 Filled down should be mixed evenly before it is put into the sample bag.

2 The stitching line should be even and neat in the sewing process to avoid serious wrinkling or inconsistent length.

3 The start button can be pressed only after putting down the transparent protective cover. Otherwise, the instrument can not run as it is automatically protected.

4 When installing the sample bag, we should try to squeeze out some air in the bag, so as not to make it difficult to install the sample bag due to the thickness of the bag.

5 The two parts of the sample bag subjected to mutual friction should be uniform in size before and after the installation. Large volume differences should be forbidden.

6 After the sample bag is sewn together, the down in the sample bag should be evenly distributed. Otherwise, the surface will be raised unevenly due to too much down in some parts. The down and other impurities on the surface of the sample bag should be cleaned up.

Test report

The test report shall indicate the following particulars for each test cushion:

1 type of apparatus

2 reference to this European Standard

3 description and designation of the tested fabric

4 description of the filling material and mass

5 number of particles passed or protruding from the fabric

6 any deviation from this European Standard and any incident likely to have affected the result

[contact-form-7 id="16355" title="Inquiry"]

Moses Maggie –

Excellent. For my lab. works well.

Carol Owen –

Very good product. Thanks manufacturer.

Ivan Camilla –

This machine was fantastic!

Irene –

It don’t take up my place. It’s ok.

Burke Needham –

Received the machine with many thanks.It looks great.