Now, mask factories in European and American countries are facing some pressure: on the one…

KN95 Mask Material Knowledge: ES Hot Air Cotton

ES hot air cotton, one of the raw materials to produce KN95 mask(N95 mask alternative listed on CDC), has been less known than the meltblown filter material, but as a manufacturer of KN95 mask, you need to know more about it.

content

- What is es hot air cotton?

- Technical parameters

- ES hot air cotton features

- How es hot air cotton is made?

- Where to purchase?

What is es hot air cotton?

Hot air cotton, also known as air vent cotton, is a new type of insulation material, is the spray adhesive cotton, silk-like cotton replacement products. Hot air wool is different from glue spray cotton. Its fixation method is not latex but in the raw materials mixed with a certain number of low melting point fibers or ES two-component fibers, in the production process through hot baking, the fibers are fused, so also belongs to one of the synthetic fiber filter cotton. Hot air cotton production is fast, large production, low cost.

The “ES” in ES hot air cotton is a composite fiber, which is an abbreviation of the English “Ethylene-Propylene Side BySide”, referring to the name of the raw material. As a new type of thermally bonded composite fiber, ES fibers are highly evaluated in the world. The “hot air” of hot air cotton refers to a process in which, after carding the fiber, the hot air from the drying equipment penetrates the fiber web and makes it heat up to bond the resulting nonwoven fabric.

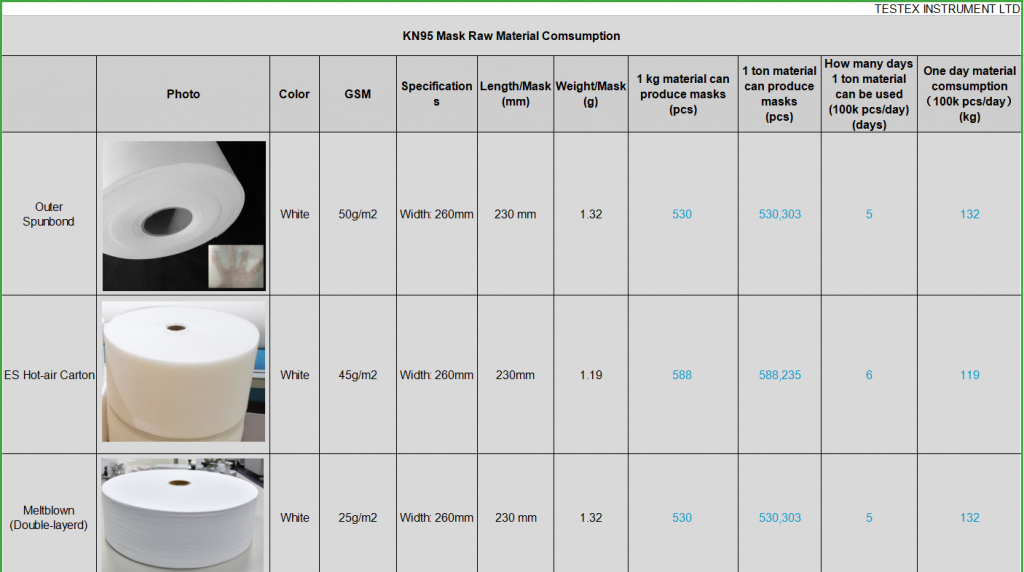

Technical parameters of es hot air cotton for KN95 mask

- Product Name:ES Hot Air Cotton

- Alias: mask cotton, ES fiber cotton, filter cotton

- Material: polyester fiber, low melting point fiber

- Production specification: 45 g/㎡ for n95, kn95 mask

- Thickness:1mm~3mm

- Width: 26cm

- Color: pure white

- Packing: Regular packaging is plastic bag into rolls, 50M or 100M/roll, can also be customized according to customer requirements.

- Features: soft and moisture-absorbent, non-drip, non-toxic, naturally degradable, warmth preservation and strong filtration performance.

- Applications: Mainly used in filtration, heat insulation, sound insulation, filling and other fields.

ES hot air cotton features

When the carded fiber web is thermally bonded by hot rolling or hot air through, the low melting point components form a molten bond at the intersection of the fibers. After cooling, the non-intersecting fibres remain in their original state, which is a form of “point bonding” rather than “zone bonding”, and the product therefore has the following characteristics.

- Pure white, fluffy, soft feel, good elasticity, warmth, good moisture absorption and breathability.

- Using natural flame retardant fiber, and no melting droplets. Has a permanent self-extinguishing effect.

- A dense carboniferous layer is formed during combustion. and low carbon dioxide content, producing only small amounts of non-toxic fumes

- Stable acid and alkali resistance, non-toxic, without any chemical effects. The product is naturally degradable and meets environmental requirements.

- Shortcomings of hot air cotton: low strength, easy to deform.

How es hot air cotton is made?

- Hot air cotton production process: Mixing – Unwinding – Feeding – Carding – Netting – Main carding – Hot air baking – Rolling – Slitting

- Blended cotton: blends of fibres, blended fibres.

- Initial opening: the mixed material is conveyed to a pre-opening machine for initial breaking and opening.

- Fine unwind: the fibre material intended by the pre-opening machine is fine unwind here, so that the curled fibre is fully stretched out for carding.

- Cotton collection: the ducts transport the fine open raw material to the cotton collector, where the open raw material is fluffy and soft.

- Carding: the cotton collector sends the fine open and loose doll cotton to the card, which then spreads the fibre combing into a net.

- Netting: the carded cotton is laid to the specified width and thickness according to the parameters.

- Hot pressing: the cotton laid in a mesh is pressed here to the specified thickness according to the specified parameters, while the fibre is first shaped and entered into the oven, where the hot pressing is completed.

- Shaping: The fibers are hot-pressed and sterilized here to the specified thickness according to the specified parameters. (The 2 steps of hot pressing and shaping are slightly different from the needle felting process, note the distinction)

- Trimming: cut the environmental protection resin cotton into the specified width or sheet size according to the specified parameters, pack the goods and complete the production.

Where to purchase?

If you need to purchase this ES hot air cotton, you can go to our mask material product page, you can download the material sheet we prepare for you to produce the KN95 mask showed below.

This Post Has 0 Comments