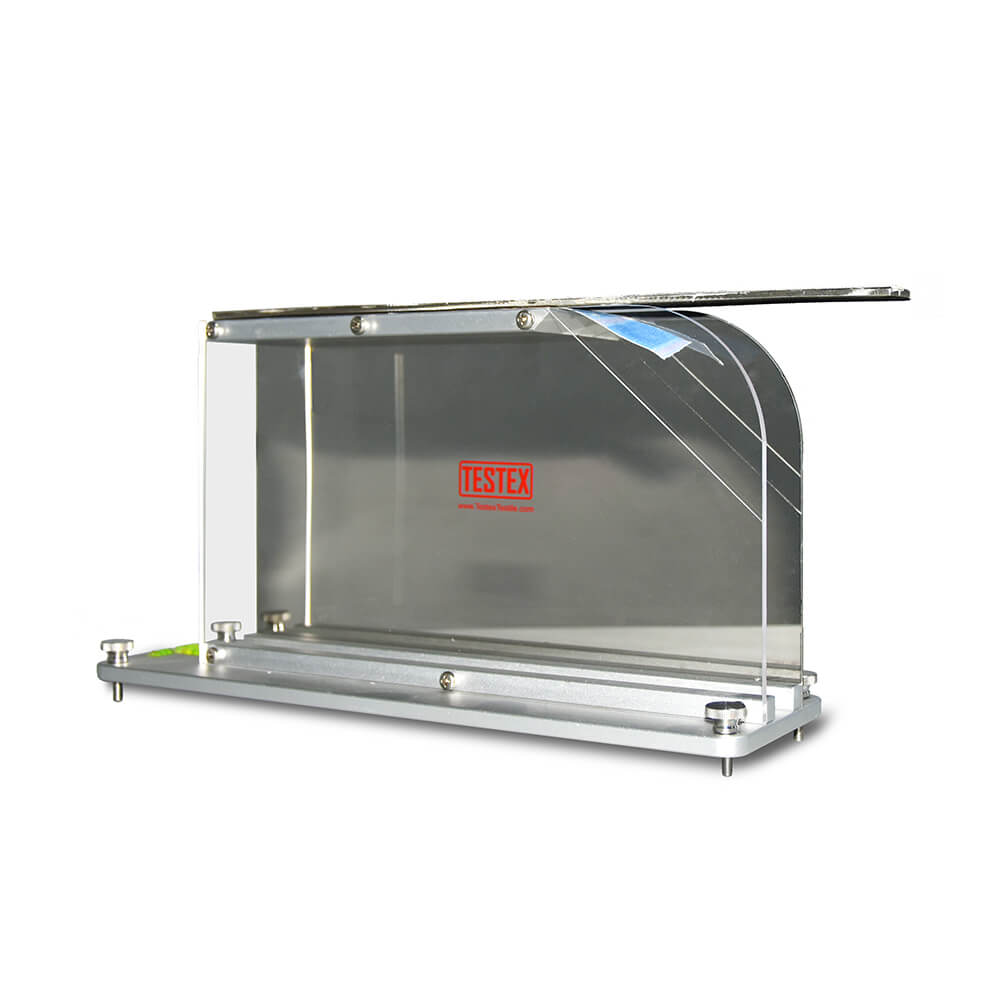

Fabric Stiffness Tester TF113

Fabric Stiffness Tester, to determine the bending height, flexural rigidity, and bending modulus of fabric by simple procedures and calculations. Shirley Stiffness Tester complies with ISO 9073-7, etc. Feel free to contact us if you want to know detailed fabric stiffness test methods and their ways of calculation.

Description

Application

Fabric Stiffness Tester is practical equipment to determine fabric’s bending height, flexural rigidity, and bending modulus. This tester provides a quick and intuitive way to know the stiffness performance of all kinds of fabrics like woven, layered, napped, knitted, pile, etc. Besides, this blog will give you detailed information about fabric stiffness and its measurement.

The Principle of Bending Stiffness Test

Place the specimen on the measuring plane of the instrument, and then slowly move the sample forward. This is done to allow one end of the specimen to gradually break away from the plane support and hang in the air. Under the influence of gravity, one end of the specimen is bent downwards. When bent to the inclined plane, measure the extension length and calculate the bending length and bending stiffness of the fabric according to the formula.

Features

- By pressing the platen against the specimen by its own weight, the platen follows the standard very closely, so there is no specimen deformation.

- The pressure plate is equipped with a scale for real-time observation of the travel.

- Made of stainless steel material, TESTEX fabric stiffness tester is anti-corrosion, and anti-rust.

Specifications

Tilt angle: 41. 5 º

Accuracy: 0.1 º

Standard Accessories

Sampling plate

Briquetting

Optional Accessories

Briquetting

Weight

| 2 kg |

Dimensions

| Length: 350 mm | Width: 100 mm | Height: 200 mm |

Standards

| Standard : ISO 9073-7 |

| Optional Standard: ASTM D1388 Method A, ISO4604, BS 3356 |

Why choose TESTEX Fabric Stiffness Tester TF113

Strictly meet standards:

All data for the Bending Stiffness Tester meet the standard parameters, for example, ISO 9073-7, etc.

Consistency with international third-party laboratories:

The test data are comparable to the test results obtained by well-known international third-party laboratories.

High reproducibility:

No matter if it’s the same samples or different machines of the same model, the results remain the same.

Longer service life:

TESTEX makes prototypes and then subjects them to rigorous reliability testing in a variety of environments to ensure achieve the expected service life.

User-friendly transparent warranty policy:

Textile testing machines, 14 months free warranty (12 months normal warranty time + 2 months shipping time). Besides, all spare parts, have 3 months free warranty.

We provide full life-cycle support for Fabric Stiffness Tester TF113. So feel free to contact our service team with any questions you may have.

Welcome to TESTEX – a professional textile testing instrument supplier – Fabric Stiffness Tester is on sale, contact us to get a detailed price quote.

7 reviews for Fabric Stiffness Tester TF113

You must be logged in to post a review.

Test Procedure

1 Take the samples from a representative section of the fabric and should not contain any folds or creases. Cut four samples of meridional and zonal by parallel or trapezoidal method, and the sample size was 200mm*25mm.

2 Adjust the instrument level. Place the sample face up on the platform, one end aligned with the front of the platform. Put up the pressure plate and make the indicator line coincide with the "zero" line of the ruler.

3 Pushing forward the pressure plate at a certain speed and driving the specimen to move forward until the specimen reaches contact with the inclined plane. Record the scale reading.

4 Lift the pressure plate and test the specimen back up again.

5 Calculate the arithmetic mean value by the values measured on the positive and negative sides as a reading of the extension length of the sample.

6 According to the formula, calculate the average value of warp, weft bending length, and bending stiffness of the fabric.

Sample preparation

- The sample should be cut from the specimen 25±1mm x 200±1mm. (Note: the ruler of the instrument can also be used as a template for drawing circles and cutting)

- A minimum of six samples should be taken, with the short side parallel to the longitudinal direction of the fabric and a minimum of six samples taken horizontally.

- All samples should be taken from a representative part of the fabric and should not contain any folds or creases.

Test Report

The test report should contain the following information:

- The number and date of the standard tested

- Sample identification

- Average warp bend length

- Average weft bending length

- Average warp bending stiffness

- Average weft bending stiffness

- Average warp bending modulus (if calculated)

- Average weft bending modulus (if calculated)

- The number of samples tested

Suzanne Christ –

Excellent!! The machine is very easy to use and its price is favorable!

Abbott Galsworthy –

Closest to results. I feel that I can trust it.

Wallis Grote –

Great! This is my 4th buying. Always satisfied.

Tobey Grey –

This fabric stiffness tester price is reasonable. 5 stars!

Gene Ford –

Excellent!!!!

Suzanne Toland –

Спасибо!

MARK.N –

Good Price / Good Product / Thank you !