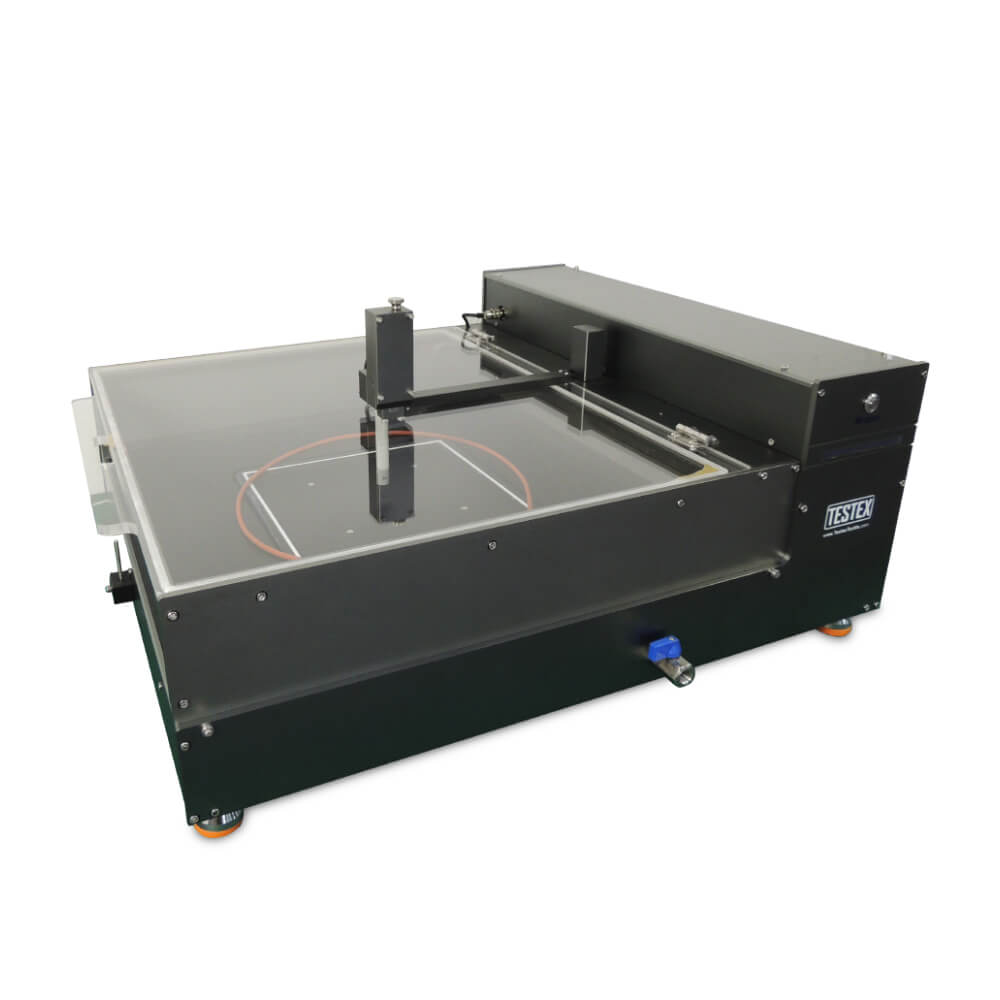

Universal Wear Tester TF213

Universal Wear Tester, is designed to test the abrasion and wear resistance of all kinds of fabrics including clothing, shoes, and technical textiles. It is mainly used to test the abrasion and wear resistance of the material under the flat state, crease state, and bending state. Besides, the Stoll Quartermaster Universal Wear Tester complies with ASTM D3514/D3885/D3886, AATCC 119/120, etc.

Description

Parameter

| Rotation Speed 100rpm (adjustable) |

| Measuring Range 25mm |

| Depth Abrasion kits, Surface Abrasion kits, Flex Abrasion kits |

| Optional order: frosting attachment, edge and fold abrasion clamp, elastomeric friction pad and base pad, photographic standards for ASTM D 3514, abrasive ‘0’ 50 yd/ roll, abrasive ‘600A’ 50 yd/ roll, abrasive ‘320J’ 50 yd/ roll |

Specification

| Model | TF213 |

| Standards | ASTM D3514, ASTM D3885, ASTM D3886, AATCC 119, AATCC 120 |

| Power | 220/110 V, 50/60 Hz |

| Weight | 80 Kg |

| Dimensions | 390 mm * 670 mm * 530 mm |

TESTEX – a professional textile testing instrument supplier – Universal Wear Tester TF213 is on sale, so you can contact us to get a detailed price quote.

The Features of Universal Wear Tester TF213

- Multi-purpose testers that can do a variety of wear tests. With the different test components, one can complete a variety of tests, such as plane wear resistance, crease wear resistance, bending wear resistance, and other tests.

- The test runs in automatic mode, which ensures more repeatable test results and avoids the inconvenience of manual operation.

- Test results are more reliable. Advanced clamping device to ensure a constant sample tensile force.

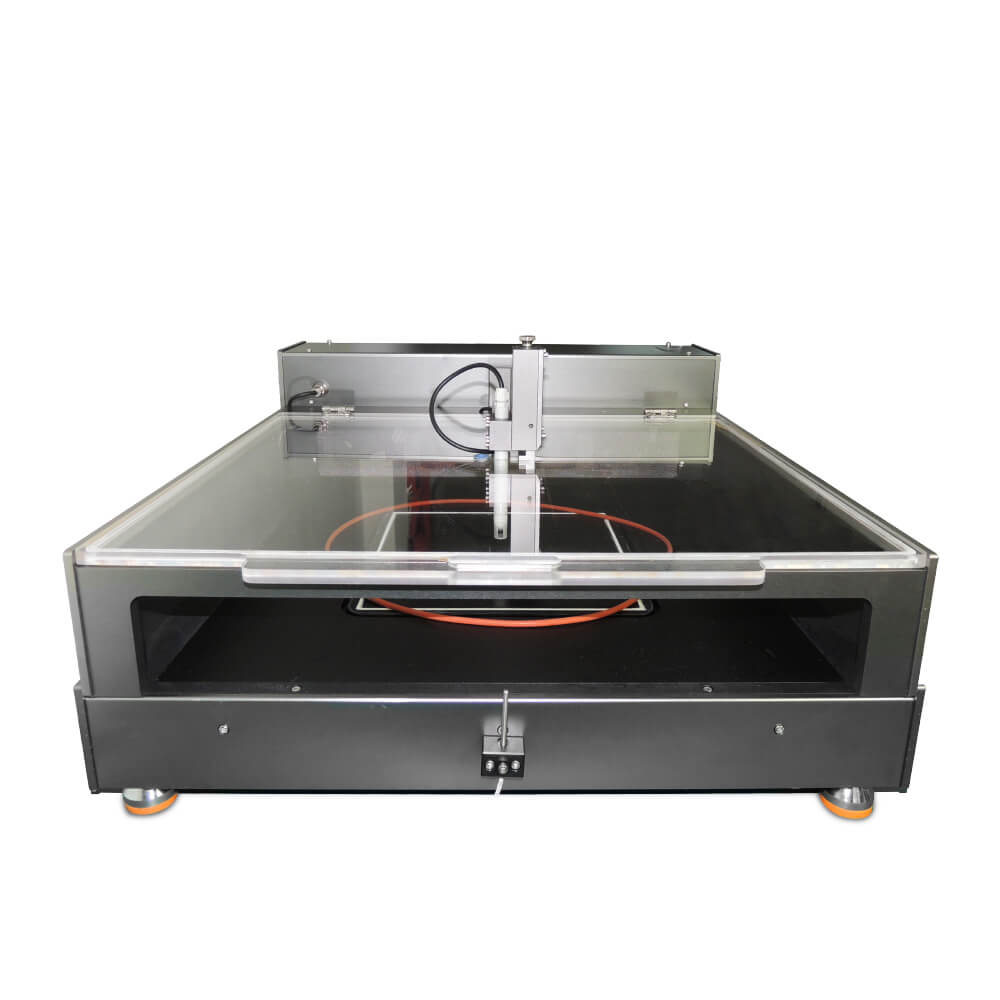

- The machine is equipped with a reciprocating table, on which the flat grinding/curved grinding test head can be mounted.

- The force value can be easily changed by changing the weight of the weights.

- Built-in timer and the mechanical cycle counter. The counter clearly records the cycle index of the sample when it breaks.

The Application of Universal Wear Tester TF213

Universal Wear Tester TF213 can be used for woven fabrics, knitted fabrics, coated fabrics, pile fabrics, socks, felts, nonwovens, deep fabrics, yarns, cords plastic films, rubber, leather, paper, and many other materials. The tested sample can be dry or immersed in water, oil, or other liquids.

TESTEX Universal Wear Tester TF213 supplies with a surface abrasion head (inflated diaphragm method) and Flex abrasion head as well as necessary weights and blades. Besides, accessories are available on request for conducting frosting, pilling, and edge abrasion tests.

Work Principle of Universal Wear Tester TF213

This instrument mainly consists of a control system and a friction system. Mount the specimen on the fixture and tighten it. Put down the upper jig with sandpaper, adjust the position of the weight to make the sandpaper contact with the surface of the specimen, set the friction times of the specimen through the control system, and start the instrument. The base of the lower fixture moves back and forth, so that the specimen and sandpaper rub against each other, and the instrument stops when the number of movements reaches the set value, and the specimen is removed to observe its wear degree.

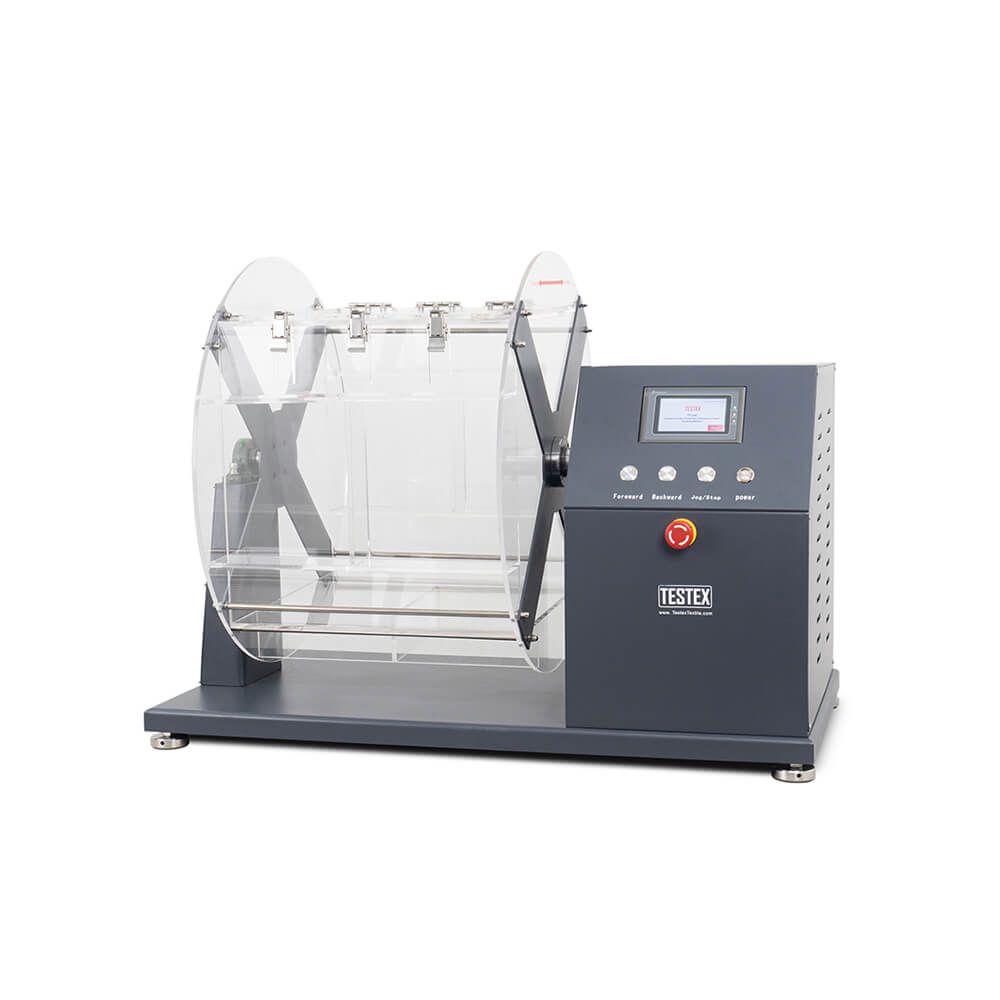

TESTEX is also providing other kinds of abrasion and pilling testers.

11 reviews for Universal Wear Tester TF213

You must be logged in to post a review.

What is the Wear Resistance of Fabric?

Wear refers to the phenomenon of damage when the fabric does repeated friction with other objects during use and wear is one of the main causes of fabric damage. Wear mainly includes three kinds of grinding: flat grinding, curved grinding, and edge grinding. Flat grinding is the reciprocating or rotating plane friction that the fabric is subjected to, such as the friction in the sleeves of clothes, the buttocks of trousers, the bottom of socks, etc. Curved grinding is the friction of fabric in a bending state, such as friction at the elbow or knee. Edge grinding mainly refers to the abrasion of the neckline, cuffs, trousers, etc.

Testing Principle of the Stoll Quartermaster Universal Wear Tester

Stoll quartermaster universal wear tester is mainly composed of a control part and a friction part. Install the sample on the fixture and tighten it. Put down the upper fixture with sandpaper, adjust the position of weight to make the sandpaper contact with the surface of the sample, and set the friction times of the sample by the control system. Start the wear testing machine, test the friction, stop the instrument when the movement times reach the set value, and then take off the sample to observe the degree of wear.

Test Range of the Stoll Quartermaster

This instrument can be used for abrasion resistance tests such as flat grinding, curved grinding, edge grinding, resistance to frost, etc. It can be used in woven fabrics, knitted fabrics, coated fabrics, pile fabrics, socks, felt, nonwoven, deep fabrics, yarns, wire rope watch film, rubber, leather, paper, and many other materials.

Stoll Quartermaster Abrasion Tester can test the wear resistance of different products or different friction ways which caused the different methods of operation. We will provide you with a more detailed manual if you purchase our products.

ASTM standard

D 123 Textile Terminology

D 1776 Textile Course about Humidity Regulation and Testing Standards

D 3885 the test method for abrasion resistance of textile fabrics(flex abrasion method)

D 3886 the test method for abrasion resistance of textile fabrics(Inflated Diaphragm Apparatus)

D 4158 the test guideline about abrasion resistance of textile fabrics(Uniform Abrasion)

D 4966 the test method for abrasion resistance of textile fabrics(Martindale Abrasion Tester Method)

D 5034 Test method for breaking strength and elongations of textile fabrics(Grab Test)

D 5035 Test method for breaking force and elongation of textile fabrics(Strip Test)

Another document:

AATCC 93 Abrasion resistance of fabrics (Accelerotor Method)

Terminology

Breakage Strength-The maximum force exerted on the material to make it broken

Wear Resistance Cycle-in the abrasion resistance test, the abrasives on the surface of the materials or the surface of the materials move back to the original position.

Detail explanation- The Wear Resistance Cycle depends on the way to work of the abrasion instrument and the applied test method. For the flex abrasion method, the material may move back and forth in a one-way direction. And for the rotary platform method, the material will move in a track of a circle; or for the inflated diaphragm method, there will be a combination of reciprocating and circular motions. For the oscillating drum abrasion test, one wear resistance cycle consists of one circular motion of the specimen.

The maintenance of the machine

1 Regularly remove lint and abrasive particles from the specimens with a vacuum cleaner or brush. The sample should not be removed from the sample clamp. Besides, the rubber pad should be wiped every time when the test is finished.

2 It is possible to make the diamond grinding wheels crack and scratch occasionally, which will block the surface of the slits. When there is a block in the surface of slits in the testing process, we can use an air hose to get rid of the debris. If there is some trouble in cleaning, we can use the wheel to repair the parts.

[contact-form-7 id="16355" title="Inquiry"]

Daniel Norton –

versatile wear test instrument, service is good

Tony.J –

Easy to use, reasonable price…if you need universal wear and abrasion tester, I recommend this.

Dawn Palmer –

What a great product! It works beyond my expectations.

Ethel Hodgson –

Extremely fast delivery! Thank you!

Yves James –

I was quite surprised how high quality this unit was for the price. Thanks manufacturer!

Arlen Mike –

This Universal Wear Tester works great for us!

Paddy Congreve –

Full package.Fast shipping.Machine is OK.

Christine Pepys –

Perfect stoll universal wear tester!

Patricia Bach –

The tester is practical, good with reasonable price.

Kelly Jasper –

Good suppiler with excellent universal wear tester!

Marlon Lucius –

Goods received. everything works. the seller answered all the questions, helped in the assembly process and running.