TabWear Abrasion Tester TF214

TabWear Abrasion Tester is often called a “TabWear machine”. It tests the wear resistance of fabrics, leather, and more. It complies with ASTM D3884/D3389/D4060, and ISO 5470. Also, TabWear Tester TF214 is easy to use. This means it costs little to train the tester to use it. We provide the TabeWear Tester for sale at a competitive price. Feel free to contact us for more information about the TabWear Tester. The TESTEX Taber abrasion tester is for sale at a summer hot promotion. Also, we are selling a series of other abrasion testers.

Description

Features of TaberWear Abrasion Tester TF214

Accurate test results

We carefully select grinding wheels and robust test arm components. Both go through strict quality control. This is to ensure that they are high-quality and stable. This is to ensure the accuracy of Taber abrasion tests.

High repeatability

We used the same set of samples and machines. We ran many tests. The results of the abrasion resistance test were the same.

High reproducibility

We tested the same set of samples. Or, we tested different machines of the same model. We did this many times. The test results are the same each time.

Longer service life

TESTEX TabWear is made of stainless steel. It resists corrosion and rust.

Easy to use

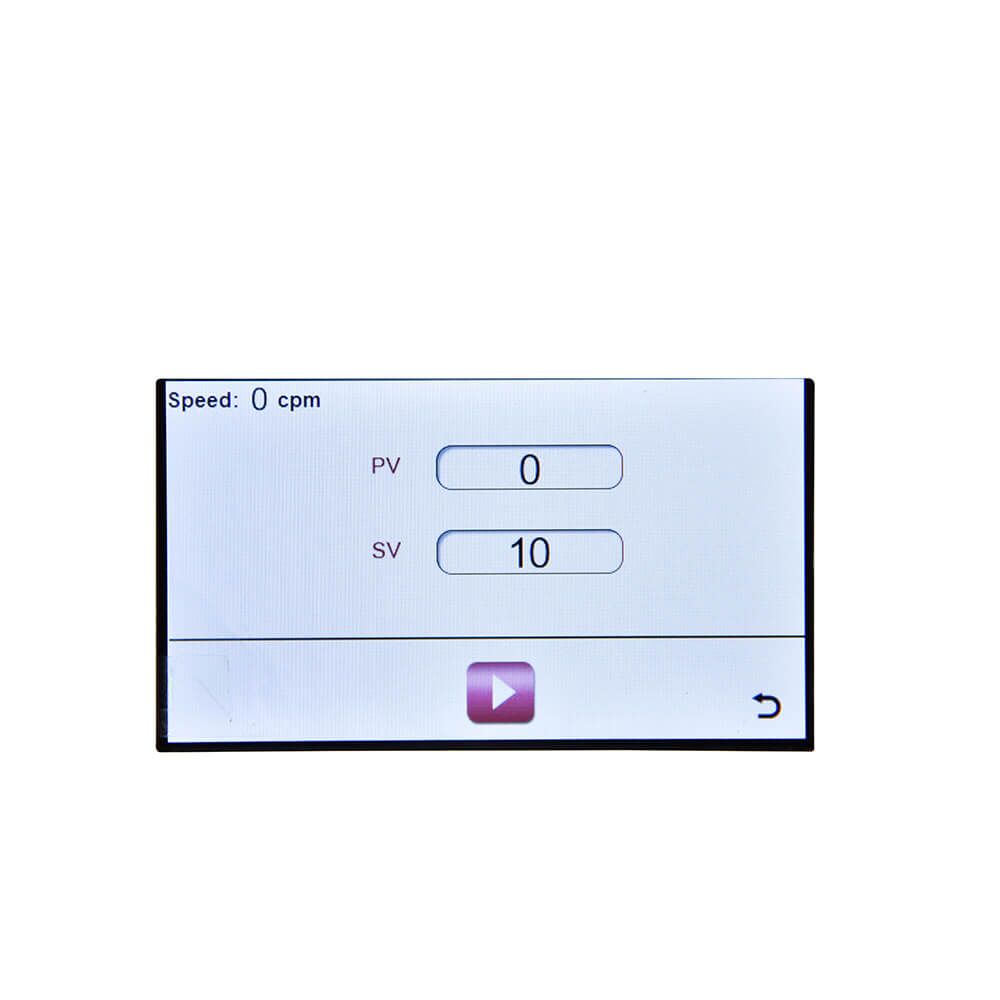

Loading and unloading grinding wheels is very simple and fast. Key parts are easy to replace. The abrasion test can be run by color touch screen. It is easy and efficient.

DC vacuum nozzle with adjustable height can accommodate different sample thicknesses.

Specifications of TaberWear Abrasion Tester TF214

| Image | ||

| Taber Abrasion Tester | TF214A (single head) | TF214B (dual head) |

| Wear Round Centre Spacing | 52.4 mm | 52.4 mm |

| Gyration Speed | 60±1 or 72±1 rpm | 60±1 or 72±1 rpm |

| Counter | 0-999,999 times | 0-999,999 times |

| Weights | 15 Kg | 25 Kg |

| Dimensions | 290mm*380mm*240mm | 530mm*380mm*240mm |

| Structure | Single head | Double head |

| Power | 220/110 V 50/60 Hz | 220/110 V 50/60 Hz |

| Load Weights | 2pcs *250g, 2pcs *750g (so can combine the weight of 250g, 500g, 1000 g) | 2pcs *250g, 2pcs *750g (so can combine the weight of 250g, 500g, 1000 g) |

Optional order

- Grinding Wheel CS – 17 / CS – 10 or others

- Paster S – 36

- Sandpaper S – 11

Standards of TaberWear Abrasion Tester TF214

| ISO 5470-1 | ASTM D3884 | ASTM D3389 | |

| optional standards: | ASTM D4060 | ASTM G195 |

Application of TaberWear Abrasion Tester TF214

The TabWear Abrasion Tester is also called the TabWear Abrasion Machine. It is a type of abrasion testing machine. It tests how well materials resist wear. You can use it for fabrics, leather, rubber, and paper. It can also test travel cases, carpets, cardboard, and clothing. Besides, you can also test glass, tile, metal, paints, varnishes, etc.

What is the TaberWear Abrasion test? What is the principle of the TaberWear abrasion tester?

Taber abrasion test is a test to determine materials’ resistance to abrasion. Abrasion resistance is the ability of a material to withstand rubbing. It can also withstand scraping or erosion. It’s defined as its ability to withstand mechanical action. The methods can test metals, composites, ceramics, and thick coatings. These coatings include weld overlays and thermal spray. Taber created the first Taber Abrasion Testing Machine. It has become a top way to test how resistant materials are to wear. You can check Taber’s abrasions on many different materials. You can use the Taber Tester to check base metals, ceramics, polymers, and fabrics. Taber abrasion tests are often performed on coated materials.

An example is a buried pipe. We test the pipe’s coating. We do this to ensure it can withstand wear and tear from soil and other ground materials.

A rotating platform places the Taber abrasion test specimen. Two friction wheels sit above the specimen. They rotate against it under a certain load. One friction wheel faces outward. The other faces inward. They form a circular wear mark. After a set number of rubbing cycles, we evaluate the wear by checking the color loss visually, using a gray card). Or, we compare the weight of the specimen before and after the test. If you want to know more about the Taber abrasion test, you can contact us via the chat box in the right-hand corner.

The abrasion index is calculated using this formula. It’s abrasion loss weight divided by the number of test revolutions, times 1000.

Tips for getting more repeatability from this TabeWear Abrasion Tester.

-

Refurbishing the wheels before the test.

-

Adjust the height of the vacuum pick-up nozzles each time. Do this when you change the sandpaper.

-

Check the surface of the wheels after a long period of testing.

Test Report of Taber Abrasion Test

A test report of the abrasive resistance should contain the following information.

1 Complete detail of the abrasive used

2 The load put on each wheel during the test

3 Details of changes in properties of the tested sample

4 Details of any deviations from the procedure specified and other situations that occur suddenly and affect the accuracy of the result.

Maintenance and Precaution of Use of TabeWear Abrasion Tester TF214

1 Must place the Taber tester on flat ground.

2 The Taber tester is not allowed to be moved when it is used.

3 Clean the platform of the Taber tester to keep it clean after the experiment.

4 Ensure the Taber tester is under a good ventilation environment when working.

5 Select the appropriate power supply and voltage, which should not be excessive to prevent burning the Taber tester.

Welcome to TESTEX – a professional textile testing instrument supplier – TabWear Tester TF214 is on sale, contact us to get a detailed Taber abraser price quote.

10 reviews for TabWear Abrasion Tester TF214

You must be logged in to post a review.

What is the Abrasion of the Material

Abrasion resistance of the material, also known as wear resistance, refers to the ability of materials to resist mechanical wear. Taking fabric or leather as an example, the finished product is often subjected to the repeated friction of other objects in the process of use, resulting in the loss and fading of the articles, thus reducing the user experience of the articles and shortening the life of the articles. There are many abrasion test methods, such as the Taber abrasion resistance test for plastic material, paper material, leather material, and so on, which is one of the most common testing methods.

Test Principle of the Taber Abrasion Resistance

Place the test sample on a rotating platform and the sample is worn by rotating friction motion with two Taber abrasion wheels under a certain load. One abrasion wheel rolls outward and the other wheel rolls inward for rubbing the sample to form a ring shape of abrasion marks. After a certain number of rub times, observe and evaluate the degree of wear and tear for the sample (Refer to taber abrasion test Wiki if you need more information).

Taber Abrasion Test Procedure

Before the Taber abraser test, choose different grinding wheels and loads according to different test materials, and then calculate the rub index. The data are shown in the below table.

[table id=911 /]

Fix the sample face up on the rotating platform and install the selected grinding wheel on the supporting bar. After selecting the appropriate load, put the support strut down so that the grinding wheel is in contact with the surface of the sample. Start the Taber abrasion machine and test it according to the number of rotation times. After the test, take off the sample, check the wear of the sample, and record the Taber abrasion test results.

Calibration steps

1 set the counter's rated revolution to 60r/min

2 press the RST key for making the number on the counter become zero

3 press the START key and start the stopwatch timing at the same time

4 when there are 60rpm on the counter, the tester will stop automatically and the stopwatch also stops timing;

5 record the time shown on the stopwatch.

Finally, repeat the above steps from step two to step five. And both times should be within the 60s ± 2s range. We should use the electronic scale to weigh the mass of weight of 250g, 500g, 750g, and 1000g respectively. And the mass of weight of 250g should be 250g±1g while the mass of weight of 500g should be 500g±2g. The mass of 750g weight should be 750g±2g while the mass of weight of 1000g should be 1000g±2g. If the weight does not meet the requirements, the mass of the weight should increase or reduce, and then be re-weighed after the adjustment until it meets the requirements.

table about selecting grinding wheels | ||

model | class | raw materials |

CS-10 | Resilient | Rugger, Abrasive grains |

CS-10F | Resilient | Rugger, Abrasive grains |

CS-17 | Resilient | Rugger, Abrasive grains |

H-10 | Non-Resilient | Ceramics |

H-18 | Non-Resilient | Ceramics |

H-22 | Non-Resilient | Ceramics |

H-38 | Non-Resilient | Ceramics |

CS-0 S-32 | Resilient | Non-abrasive rubber |

S-42 S-33 | Resilient | Sandpaper strips |

CS-5 | Resilient | Wool Felt |

S-35 | Non-Resilient | Tungsten Carbide |

The Taber abrasion tester is for sale now, please contact us if you would like to know more about the abrasion resistance test.

Taber Abrasion Test Method as ASTM D1044

Test Method:

Under the set pressure, the specimen is rotated at the set speed so that the specimen is rubbed against the specified friction head a set number of times.

1. The grinding wheel contacts the end of the pressurized arm and rotates, and when the grinding wheel stops on the test piece, the periphery of the grinding wheel contacts the surface of the test piece, and the running direction of the periphery of the grinding wheel forms an acute angle with the running direction of the test piece.

2. The distance from the edge of the left wheel to the center of the test piece holder is equal to the distance from the edge of the right wheel to the center of the test piece holder, which is 26.6 mm.

3. The vertical distance between the center of the grinding wheel pressurized arm shaft pivot point and the top of the specimen holder is 25mm.

4. The specimen holder should be able to easily install and fix samples of different thicknesses.

5. It should be ensured that the pressure added to the specimen by the friction head is vertical pressure, and it is easy to adjust the pressure.

6. There should be a dust-absorbing device, and the distance between the dust-absorbing mouth and the specimen can be adjusted from 2mm to 7mm to suit the requirements of samples of different thicknesses in order to absorb the particles more effectively and ensure the repeatability of the experiment.

[contact-form-7 id="16355" title="Inquiry"]

A: The single head written in catalogue is only for reference, we can also do dual head. Please contact us to get more details.

Q: Do this machine have vacuum system with suction hose?

A: Yes, it does.

Q: Can this taber abraser set with speed 72 ± 2 rpm and 60 ±2 rpm?

A: Yes, the machine is equipped with a rotater to set the speed.

Q: What is the standard that the Gyration speed be 70 rpm +/- 1rpm follows?

A: The parameters in the catalog is written with ISO 5470-1, and we can also do with other standard like ASTM MD 3884. Please contact us to get more details.

Joren Kandel –

Elegant design, and efficient taber abrasion tester

Joson Williams –

For this taber abrasion tester from testex, I can not say it is perfect, but it do solve my problem with a competitive cost, service is good!

Payne Bell –

使いやすい

June –

This Taber abraser performs well in my laboratory. Simple operation! Recommend!

Harry Berkeley –

Excellent seller and a good figment

Robert –

The taber abrasion tester price is resonable. And its performance is good too.

Jill Charlotte –

Happy to cooperate with this abraser suppiler. Great abrasion machine!

David –

Good contact with the seller.

Mark –

빠른배송!!좋은제품!!

John Emerson –

This machine is great. Beautiful appearence, easy operation.