Now, mask factories in European and American countries are facing some pressure: on the one…

Why are the Meltblown Nonwoven Face Masks You Produce not up to the Testing Standards?

N95 or KN95 filtration of less than 95%? Feeling breathless while wearing a mask? What kind of masks can be used in a medical setting? The quality of the mask quality inspection mainly considers performance …….

The meltblown nonwoven, the core material of the mask, determines to a large extent whether the masks made are qualified. Good meltblown nonwoven masks are generally not too bad, meltblown nonwoven test reports generally do breathing resistance tests, filtration efficiency test, microbial test, and other three items. If you want to produce a mask, you should first test the meltblown nonwoven to see if it is qualified, so that the meltblown nonwoven does not fail, resulting in the production of the mask is not qualified then it will be a loss.

Most Penetrating Particle Size (MPPS): In particulate matter filtration efficiency testing, particulate matter diameters that are too large or too small are easily filtered by the face mask, so there is a range of particulate matter diameters that are most difficult to filter, which we call the most penetrating particle size. For example, the 2019-nCoV is around 120nm in size and are among the most difficult particle species to filter; bacteria are around 3µm in size and are relatively easy to filter. Viral blocking is basically equivalent to particulate matter filtration efficiency.

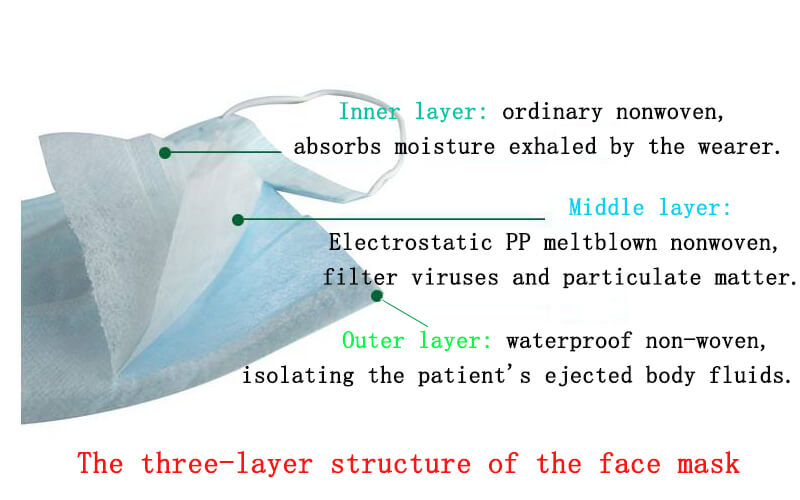

Principle of filtering particulate matter with a 3-layer face mask

The masks we use are generally 3 layers and above. Inner and outer materials, mostly polypropylene spunbond nonwoven materials, the particle filtration efficiency of which is limited. The middle layer to play a particle filtering role with the electret polypropylene meltblown nonwoven materials, the material can use electrostatic adsorption of particles, thus greatly improving the filtration efficiency.

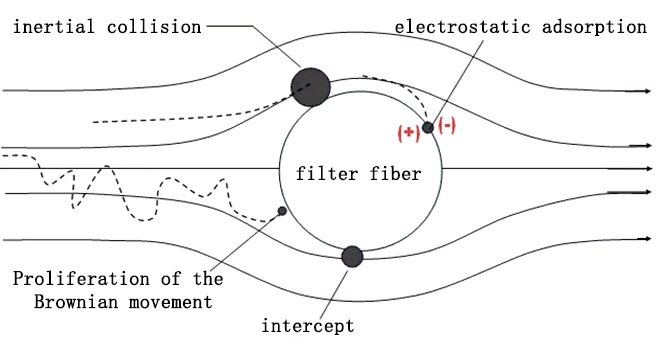

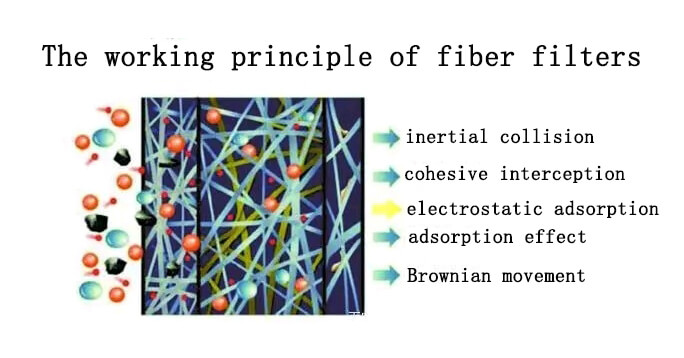

The filtration of particulate matter by filtration materials mainly has the effect of gravity settlement, interception, inertial collision, diffusion, electrostatic adsorption, etc. Under the joint action of various filtration mechanisms, there is a minimum value of filtration efficiency for particulate matter with an aerodynamic particle size around 0.3µm, which is commonly known as the most easily penetrating particle size (MPPS).

the main filtration mechanisms of 3-layer face masks are as follows

1 Diffuse deposition: The particle Brown is adsorbed by molecular gravity as it moves through the filter fibers. It is easiest to capture small-scale particles, fine fibers, and particles with low velocity motion.

2 Retained sediment: Larger particles moving with the airflow are trapped by the mechanical sieving action of the filter material.

3 Inertial deposition: As the particles pass through the mesh channel of the filter material, they are detached from the airflow due to inertial action hitting the filter fibers and are trapped by molecular gravity. Large particles, high density, and fast velocity have a good interception.

4 Electrostatic attraction deposition: The particles are deposited by the electrostatic action of the filter fibers.

The smaller the particle, the stronger the 1 and 4 deposition effect, and the larger the particle, the better the 2 and 3 effects, so not the smaller particle the harder it is to filter. Combining the synergy of the four filtration mechanisms, the most easily penetrated particle size is 0.1µm to 0.3µm for common mechanical media.

Main testing items and instruments for meltblown nonwoven face masks

The meltblown nonwoven fabric has a finer fiber structure than spunbonded nonwoven fabric, and therefore has better trapping properties for tiny particles. The use of meltblown nonwoven fabric with good processing performance, excellent chemical resistance polypropylene as raw material, better filtration efficiency, insulation performance is excellent, in addition to high porosity, good breathability. The main test properties are as follows.

1 Appearance quality inspection: holes, impurities, odors, micro holes, crystalline points, melts, stiff wires, unreinforced area, sparse mesh, width deviation, color difference, joint quality.

2 Intrinsic quality testing: Mass deviation rate per unit area, longitudinal fracture strength, transverse fracture strength, longitudinal and transverse fracture elongation, hydrostatic pressure, permeability.

3 Microbiological indicator testing: Total bacterial colonies, total fungal colonies, coliforms, pathogenic septic bacteria.

In addition, with reference to the relevant face mask standards, companies also have to conduct particle filtration efficiency test, bacterial filtration efficiency test, ventilatory resistance and pressure difference test, airflow resistance and breathing resistance test for meltblown nonwoven. Common test items for each national mask standard are listed below.

Examples of test items for the Chinese standard for face masks:

| YY/T 0969 Disposable medical masks | YY 0469 Medical surgical face masks | Medical protective face masks GB 19083 | GB/T 32610 Daily protective face masks | GB 2626 Labour protective face masks |

| Strong fracture of the mask strap at the point of connection with the mask lift | Strong fracture of the mask strap at the point of connection with the mask lift | Strong fracture of the mask strap at the point of connection with the mask lift | Strong fracture of the mask strap at the point of connection with the mask lift | Tension on the headband |

| Bacterial Filtration Efficiency (BFE) | Bacterial Filtration Efficiency (BFE) | / | / | / |

| respiratory resistance | respiratory resistance | respiratory resistance | respiratory resistance | respiratory resistance |

| Ethylene oxide residue | Ethylene oxide residue | Ethylene oxide residue | Ethylene oxide residue | / |

| / | synthetic blood penetration | synthetic blood penetration | / | / |

| / | Particle Filtration Efficiency (PFE) | Non-oily particle filtration efficiency | Particle Filtration Efficiency (PFE) | Particle Filtration Efficiency (PFE) |

| / | Flame resistance | Flame resistance | / | Flame resistance |

| / | / | / | Outlook | Outlook |

| / | / | / | PH value | Breathing valve airtightness |

| / | / | / | Formaldehyde content | / |

| / | / | / | Color Fastness | / |

Examples of test items for the European standard for face masks:

| EN 14683 + AC: Medical face masks testing | BS EN 149 + A1: Respirator testing |

| Material strength test for face masks | Material strength test for face masks |

| Face mask constant temperature and humidity pretreatment | Face mask constant temperature and humidity pretreatment |

| Bacterial Filtration Efficiency (BFE) | / |

| Synthetic blood penetration test | / |

| Ethylene oxide residue testing | / |

| Permeability – gas pressure difference | Breathing Resistance Test |

| Microbial testing | Microbial testing |

| / | Particulate matter filtration efficiency |

| / | outlook |

| / | Flame resistance |

| / | leakage rate |

Examples of test items for the USA standard for face masks:

| ASTM F2100: Medical face masks testing | NIOSH 42 CFR Part 84: Labour protection mask N95 testing |

| Material strength test for face masks | Material strength test for face masks |

| Breathing Resistance Test | Breathing Resistance Test |

| Liquid spill protection | / |

| Bacterial Filtration Efficiency (BFE) | / |

| Synthetic blood penetration test | / |

| Particulate matter filtration efficiency | Particulate matter filtration efficiency |

| flame spread | flame spread |

| / | outlook |

| / | leakage rate |

Example of meltblown nonwoven not testing up to standard

1 Raw materials are not up to standard

The Melt Flow Rate of meltblown polypropylene is higher, stable liquidity, meltblown polypropylene basically supply large manufacturers, the market is difficult to buy. However, some manufacturers will buy ordinary polypropylene and produce meltblown nonwoven through some processes. The biggest problem with ordinary polypropylene is that it may lead to uneven flow of melt, and some over-drafting, which may easily cause shot (lumpy polymer), making the fiber thickness uneven and affecting the breathability and filterability of meltblown nonwoven. Most of the low-end meltblown nonwoven production lines are not electrostatic electret processing, the filtration efficiency is only about 60% at the highest.

2 Meltblown nonwoven production process parameter setting is not up to standard

The meltblown nonwoven is made of meltblown polypropylene, which is plasticized and melted, and the fine filaments are sprayed out at high temperature and high speed, naturally cooled in the air.

The size of the extruder equipment affects the width and efficiency of the production of meltblown cloth; the good or bad of the die head to determine whether the cloth can be sprayed, the roller, transformer is best to choose a good one; of course, the meltblown machine die, melt temperature, air volume, air speed, electrostatic electret and other parameters also affect the melt spray cloth quality. The raw materials, equipment and process parameters are well controlled, the small meltblown equipment can still produce the standard 95%, 99% meltblown nonwoven.

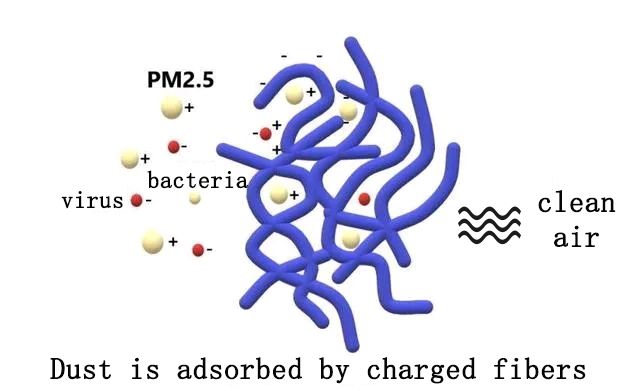

3 The filtration level of meltblown nonwoven is not up to standard

Usually, there is a problem with the electrostatic electret process during the production of meltblown nonwoven, resulting in the meltblown nonwoven electrostatic adsorption is not up to standard. The structure of meltblown nonwoven is very simple, is like a fishing net, meltblown nonwoven gap is actually much larger than the virus, the virus is about 0.1um, the gap of nonwoven fabric is 1um, or even larger, just by blocking is not able to stop. It also depends on the combined effect of these theories.

The most important reason why meltblown nonwoven filter well is the electrostatic adsorption that keeps viruses away.

Meltblown nonwoven face masks: conventional testing instruments, how to testing?

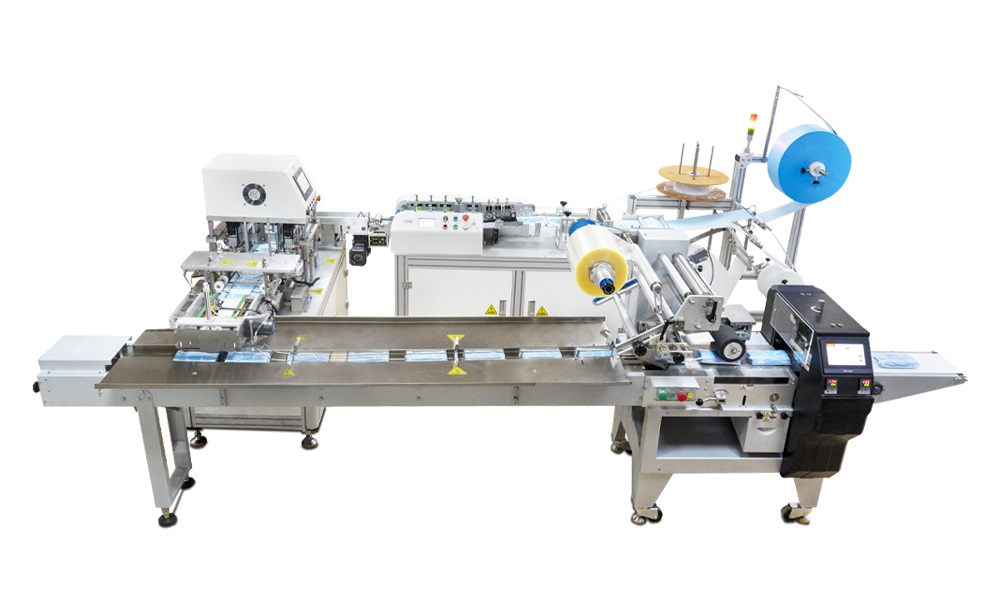

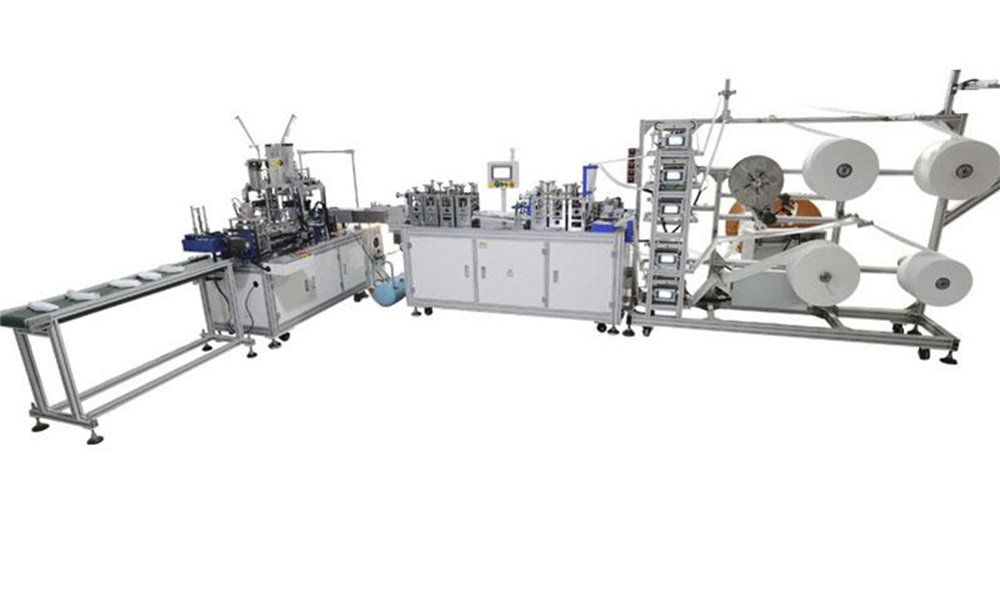

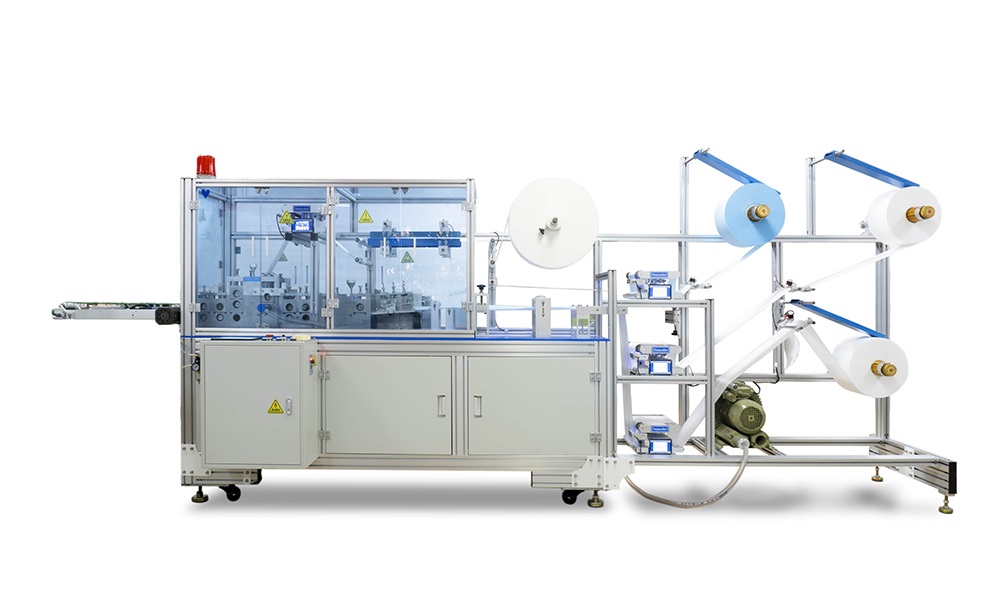

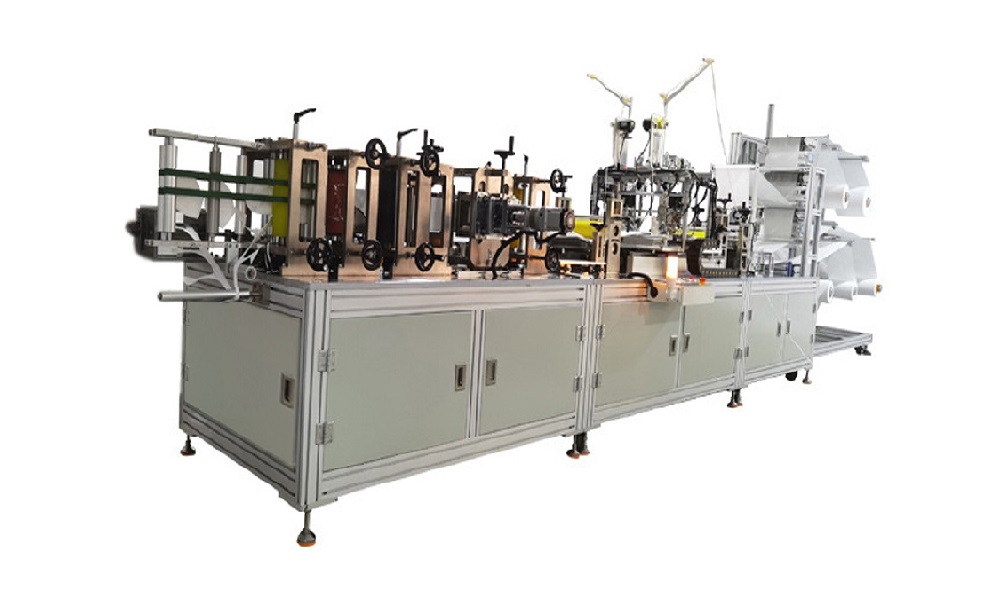

To make it easy for those who want to produce antiviral face masks, TESTEX offers all kinds of mask manufacturing machine.

This Post Has One Comment

Leave a Reply

You must be logged in to post a comment.

Hi

How much do you sell 1 box of 3 ply face mask for?