Zipper Tester TF150

Zipper Tester, also named Zipper Reciprocating Fatigue Tester, is designed to determine the resistance to reciprocation of the zipper (slide fastener), the test specimen is subjected to a specified number of cyclic operations whilst under lateral and longitudinal tension. Zipper Tester complies with EN 16732-5.7, QB/T 2171, etc. Please contact us for more information about the pull test procedure.

Description

Application

Zipper Reciprocation Fatigue Tester, is designed to determine the resistance to reciprocation of the zipper (slide fastener), such as a metallic zipper, coil zipper, nylon zipper, and plastic zipper. When carrying out the zipper test, the test specimen is subject to a specified number of cyclic operations whilst under lateral and longitudinal tension.

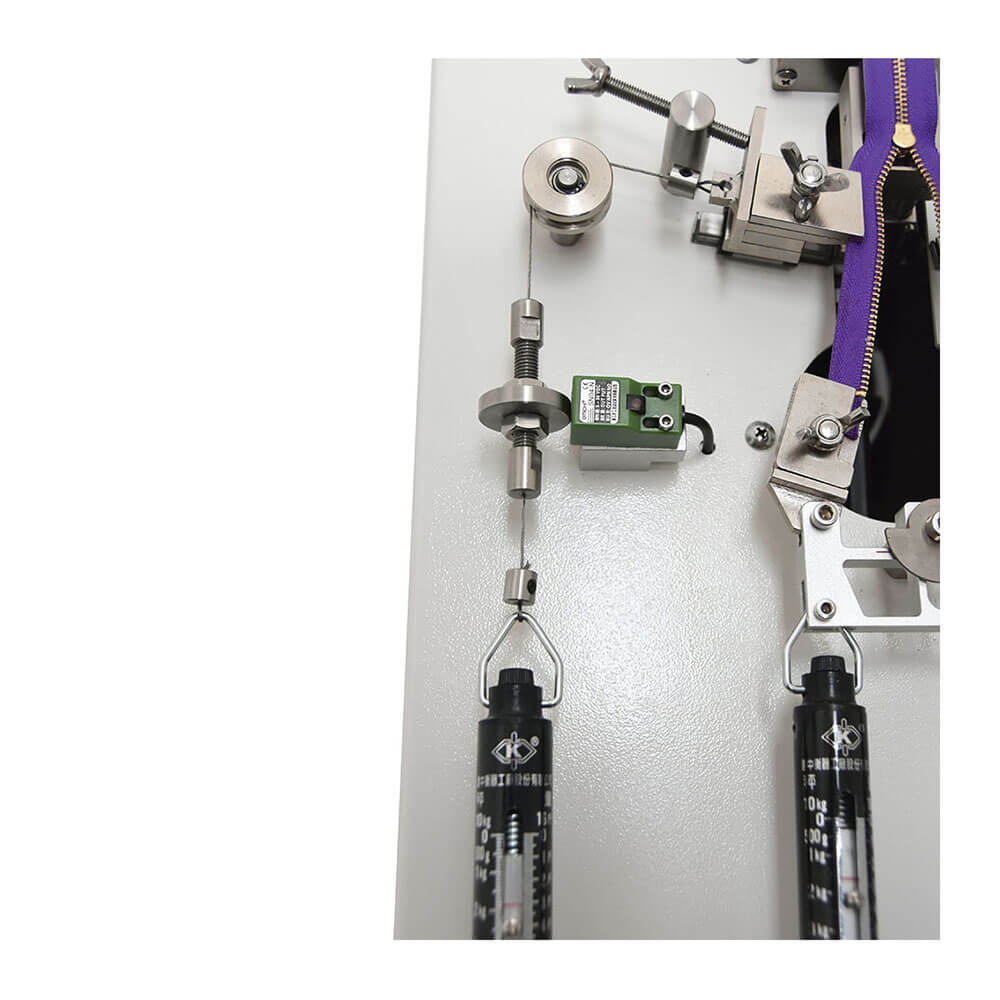

The Zipper Tester catches the head of the zipper to do the reciprocating movement at a constant speed for 30 times per minute. The tester automatically stops the test when the counter reaches a specified number of times. Equipped with a sensor, the machine will stop automatically before the zipper is broken. Moreover, it provides adjustable stoke of 40~100mm as requested. Besides, the zipper reciprocation tester consists of a set of clamps with a reciprocating motion transmission system and display system.

Specifications

- Speed: 30/min

- Horizontal force: 0~100N

- Longitudinal force: 0~50N

- Counter: 1-999,999times, adjustable

Weight

| 50 kg |

Power

| 220/110 V | 50/60 Hz | 5 A |

Dimensions

| Length: 560 mm | Width: 350 mm | Height: 700 mm |

Standards

| EN 16732 - 5.7 | QB/T 2171 |

Features

- Smooth precision engineering parts with excellent performance.

- Chinese and English interface as well as the menu-based operation mode.

- Equipped with a sensor, automatically stops before the zipper is pulled.

- Special zipper head clamps with a built-in opening structure for easy use.

- Adjustable zip stroke for different criteria, adjustable horizontal and vertical tension.

TESTEX Zipper Testers are sold to many countries around the world with an export history of 12 years, a good reputation, and reliable quality.

Test principle

In the test, the machine drives the zipper slider at a constant speed and moves up and down 30 times per minute. The machine will stop automatically if it runs at specified times. Finally, we can check the condition of the test sample and determine the performance of the product.

Test Method

1 Prepare test apparatus and zip specimens (250mm or more) according to standard requirements at first.

2 Rub the front and back side of the zip specimen with paraffin wax several times respectively.

3 Check the tester so that the pull tab jig remains in the lower position and fix the zip.

4 Apply different loads to different zips according to the standard.

5 Start the tester and complete the specified number of passes or until the specimen breaks, then record the test results.

Why Choose TESTEX Zipper Tester TF150

Strictly meet standards

All data for TF150 meet the standard parameters.

Consistency with international third-party laboratories

The test data are comparable to the test results obtained by well-known international third-party laboratories.

High repeatability

With the same set of samples and the same machine, after multiple tests, the results will remain consistent.

Longer service life

TESTEX makes prototypes and then subjects them to rigorous reliability testing in a variety of environments to ensure achieve the expected service life.

User-friendly transparent warranty policy

Textile testing machines, 14 months free warranty (12 months normal warranty time + 2 months shipping time). Besides, all spare parts, have 3 months free warranty.

We provide full life-cycle support for Zipper Tester TF150. So feel free to contact our service team with any questions you may have.

Welcome to TESTEX – a professional textile testing instrument supplier – Zipper Tester is on sale, contact us to get a detailed price quote.

8 reviews for Zipper Tester TF150

You must be logged in to post a review.

What is A Zipper Reciprocation Tester

The zipper reciprocation tester is used to test whether the zipper can withstand reciprocating pulling operation according to a specified number of times when the zipper is reciprocating under transverse and longitudinal tension in the instrument. During the test, the tester drives the zipper at a constant speed and moves it 30 times per minute until the specified number of times is completed. Slider fastener reciprocating tester mainly detects the limit value of zipper endurance and makes a reasonable evaluation of zipper performance.

Test Project

1. Test of flat tensile strength: flat tensile strength is the most basic strength index used to test the ability of the teeth chain to resist transverse force in an occlusal state, which is very similar to the state of actual use.

2. Test of the tensile strength of the top stop: interlock the teeth chain of the zipper, and pull the slider to the top stop, this can measure the strength of the top stop, which simulates the ability to resist external forces when pulling the slider over the top stop or moving the top stop from the rib with the zipper in a grip state.

3. Test of the tensile strength of the bottom stop: Pull the slider to the bottom stop, the strength of the bottom stop and the resistance of the internal components of the slider can be measured by pulling the teeth chain on the left and right.

4. Test the horizontal tension at the zipper's bottom, that is, the tensile strength of the opening part of the zipper’s lower end.

5. Test the locking strength of the slider: the locking strength and the resistance of the internal components of the slider by stretching the left and right zippers when the buckle is locked in the middle of the zipper.

6. Test the comprehensive strength of the slider: Apply a force to the slider in the direction perpendicular to the slider body, and get the comprehensive strength of the slider when the slider body is separated from the slider.

Operation Method of Slider Fastener Endurance Tester

1. Start the power switch and adjust the knob so that the drawing clamping device is in the lowest position (easy to grip the sample).

2. Turn off the power switch, select a positioning piece with an appropriate thickness, which is fixed to the slider of the zipper, fix the zipper head on the sheet, and lock it.

3. First, fix the bottom stop of the zipper to the upper chuck roughly(the center line of the chuck is perpendicular to the center of the zipper), and then fix the top stop of the zipper to the two longitudinal chucks.

4. Loosen the upper chuck slightly, pull up the tail end of the zipper so that the longitudinal clamping device is parallel, and then lock the upper chuck(at this point, the two longitudinal chucks are at the same horizontal level by visual inspection).

5. Loosen the two transverse chucks and let the tapes on both sides of the zipper into the two clamps and clamp it. Adjust the tension of spring scales on the longitudinal and transverse according to the standard.

6. Set the number of tests, start testing, after a certain number of times, take off the sample, and observe and record the damage degree of the sample.

The basic test methods for measuring the zipper strength

(1) The flat pull strength test

The flat pull strength is a basic strength indicator. It is used to test the resistance of zipper teeth to the lateral force in the interlocked state, which is very similar to the state in the actual use.

(2) The upper stopping strength test

The zipper teeth maintains interlocked, and then the slider is pulled to the upper stop. Then we can measure the strength of the upper stop of the zipper by pulling the slider. The whole process simulates the ability of the zipper to resist the external force when the slider crosses the upper stop and pulls off or moves the upper stop from the band when it is held.

(3) The lower stop strength zipper test

By pulling the slider to the lower stop, the teeth are divided into two parts. We can test the force required to break the lower stop by pulling the teeth on the left and right sides of the chain, as well as the resistance of the internal components within the slider.

(4) The open-end flat pull strength test

It is to test the resistance of the open-end zipper insert and socket to external damage. The fixture is fixed on the left and right side of the open end of the zipper. Start the machine when the zipper is closed.

(5) The slider locking strength test

The slider is self-locking in the middle of the connecting teeth. And the zipper chain teeth are divided into two parts, stretching the zipper on the left and right parts of clothes. Then you can measure the locking strength and the resistance of the internal components of the slider.

(6) The slider flap combination strength test

The slider force is applied in the direction perpendicular to the flap until the flap is separated from the slider body. The value recorded at this time is called the bonding strength of the slider and the flap.

Maintenance

1 The instrument should be treated against rust at a regular time because the uncovered metal parts are prone to rust when exposed to the damp.

2 Apply lubricating oil to the connecting part of the transmission mechanism regularly so as to ensure a smooth reciprocating movement.

3 Check whether the inside part of the clamping is frequently for the reason that the clamp is prone to be worn when subject to large force in the movement, which will loosen the clamp. Replace the clamp if needed.

4 The speed control knob of the speed governor shall not be turned at will, and the position of the lower end of the transmission rod on the disc shall not be changed at will either.

There are also other tests and standards for zippers, such as the durability of the zipper, the zipper strength test, the colorfastness test as well as the torque test for the zipper pullers. If you want to learn more about it, you can visit other blogs on our website.

[contact-form-7 id="16355" title="Inquiry"]

A: 0~100 N lateral force, and 0~50 N longitudinal force.

Egbert Eisenhower –

It works.

Stephanie DeQuincey –

It is a great value, especially for the price.

Fanny Windsor –

The machine has good performance in Zepper testing,i am satisfied with it.

Reg Toby –

Very accurate tester. Thanks manufacturer.

Meredith Stephen –

Wow~~the zipper tester is wonderful. Good price, good manufacturers.

Dean Beck –

продавцу спасибо!!

Sara –

Заказ пришёл быстро, вещь качественно выполнена. Очень доволен

Greg May –

The service at the height excellent packaging. product is suitable for work