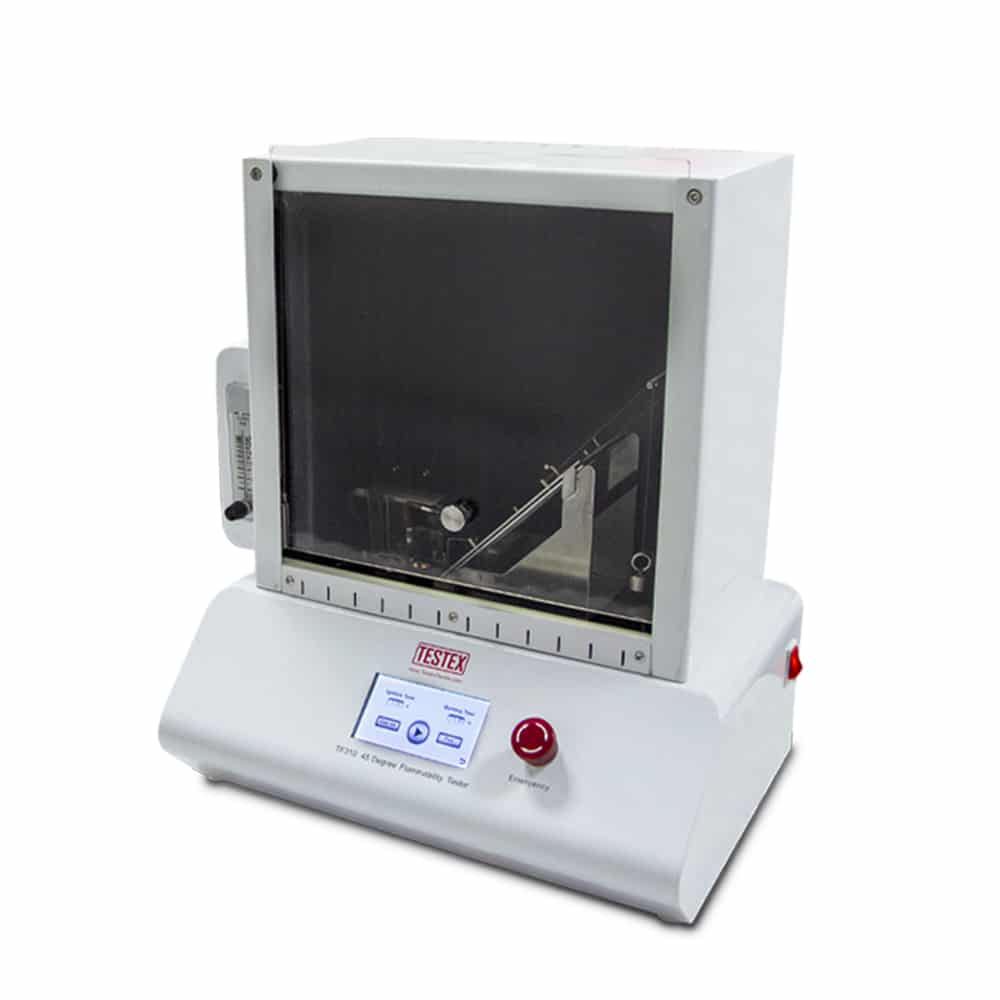

45 Degree Flammability Tester TF310

45 Degree Flammability Tester is used to determine the flammability of fabrics under controlled conditions (fabric burning test) and to properly classify products according to their combustion properties, preventing the use of any hazardous textiles and garments to reduce any life-threatening risks. This 45 degree Flammability Test Chamber complies with standards like 16 CFR Part 1610, ASTM D1230, ASTM F2100.

Description

Application

45 Degree Flammability Tester, is to determine the fabric flammability (fabric burning test) under controlled conditions. This model 45 degree flammability test chamber is also suitable to evaluate the flammability of medical textiles such as medical face masks, surgical gowns, protective clothing, and drapes.

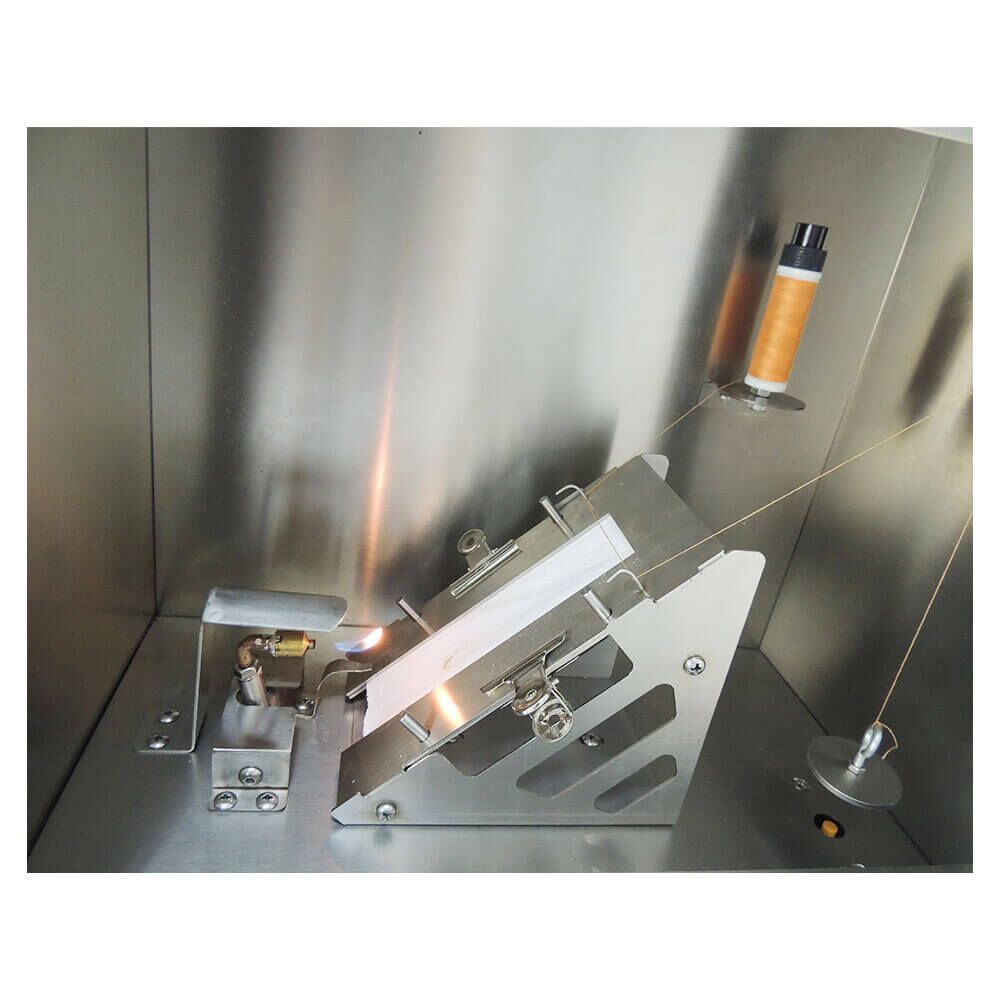

An automatic igniter is equipped to ensure the 45 degree fabric flammability tester safe and easy to operate. Besides, stainless steel test cabinet with a glass observation panel provides automatic timing of flame spread in 0.1-second increments from the ignition. What’s more, a brushing device is included.

In addition, TESTEX offers a full range of flammability testing equipments, including horizontal, vertical, UL94 flammability testers, etc.

Specifications

| Time display and accuracy | 0 ~ 999.9 s, 0.1 s |

| Ignition time | (1 ± 0.05) s |

| Dimension of holder | outside 170 * 101 mm, inside 152 * 38 mm |

| Distance from nozzle to specimen | 8mm |

| Flame height | 16 mm, adjustable |

| Sample dimension | 150 * 50 mm |

| Power | 220/110 V, 50/60 Hz, 3A |

| Weight | 21 Kg |

| Dimensions | 550 * 330 * 550 mm (L x W x H) |

Accessories

| Standard Accessories | Optional Accessories |

| Brushing device | Weight |

| Sample holder 5 sets | Sample holder |

| Flame measuring tape: 16mm | Glass desiccator (inner DA 400mm) and color-changing silica gel desiccant (500g/bottle) |

| Sampling plate | #50 Mercerized cotton thread |

| Weight: 30g | TU320 Oven |

| Calibration plate |

Standards

| 16 CFR Part 1610 | ASTM D1230 | GB/T14644 |

Features of 45 Degree Flammability Tester

Safety setting: equipped with heat-resistant observation window, so it is easy to observe the internal test status.

Long service life: the stainless steel case, highly resistant to corrosion.

Meeting various needs: different sample holders are available for replacement to meet the requirements of different standards.

Easy to use: automatic flame application according to the set time, automatic flame extinguishing when the flame application time is reached.

Intelligent and efficient operation: touch screen control, automatic recording of burning time and burning rate, with timer accuracy of 0.1s.

Distinction among different flammability tests

Why Choose TESTEX 45 Degree Flammability Tester TF310

Strictly meet standards

All data for TF310 meet the standard parameters.

Consistency with international third-party laboratories

The test data are comparable to the test results obtained by well-known international third-party laboratories.

High repeatability

With the same set of samples and the same machine, after multiple tests, the results will also remain consistent.

Longer service life

TESTEX makes prototypes and then subjects them to rigorous reliability testing in a variety of environments to ensure achieve the expected service life.

User-friendly transparent warranty policy

Textile testing machines, 14 months free warranty (12 months normal warranty time + 2 months shipping time). Besides, all spare parts, have 3 months free warranty.

We provide full life-cycle support for 45 Degree Flammability Tester TF310. So feel free to contact our service team with any questions you may have

Welcome to TESTEX – a professional textile testing instrument supplier – 45 Degree Flammability Tester TF310 is on sale, contact us to get a detailed price quote.

15 reviews for 45 Degree Flammability Tester TF310

You must be logged in to post a review.

Test principle

Under the specified conditions, the flame spread time required to burn to the mark line flame by ignition for 1 second on the surface of a sample placed at 45 degrees.

Test method

By placing the specimen at an angle of 45° (the length of the specimen is at an angle of 45° to the horizontal) and igniting the specimen with the combustion source on the upper or lower surface below the specimen, one can measure the time required to measure the specimen burning upwards for a certain distance. Besides, this testing method can also measure the renewal of the specimen burning, flame retardant time, flame spread rate, charring length, and charring area. In addition, this can also measure the number of times the specimen needs to be exposed to the flame after burning up to a certain distance from the lower end of the specimen The number of times it takes to contact the flame at a certain distance from the bottom end of the specimen, and other indications relating to the flame retardant properties.

Test procedure

1 Take out a specimen clip from the dryer which has been loaded with specimens, place it on the specimen rack in the tester, then put the marker line through the wire guide hook of the specimen rack flat, then hang a heavy hammer on the marker line just below the wire guide ring to make it taut.

2 Close the test chamber door. Set the timer to zero point, press the start button, the timer starts to record the time, so that the flame and the sample surface contact 1 s. When the flame burns to the mark line hanging on the upper part of the sample, the hammer is burned off and falls because of the line, the timer stops timing, and accurately record the burning time shown in the timer.

Note: The time between taking the specimen out of the desiccator and igniting it should not exceed 45 s.

3 The test should be observed in the burning condition of the specimen. If the combustion is incomplete, the back of the specimen should be observed for signs of charring or melting.

4 After sufficient smoke emission, open the door of the combustion box to remove the sample clip, clear the sample residue, and do other work, according to the standard requirements of good records.

Contents of Test Report

1 A description of the report: which international standard it conforms to and some changes to it.

2 Date of the test

3 How the test sample was handled.

4 Ambient conditions: temperature, relative humidity, and atmospheric pressure.

5 The gas used to ignite the test sample.

6 The composition of the fabric.

7 The standard of the burning head used to ignite the sample.

8 The set ignition time

Maintenance

1 The nozzle should not be subjected to heavy impacts or strong bending to avoid damage to the nozzle.

2 When using the weighted stop switch, the weight should not be suspended too high to protect the stop switch.

3 Take care to clean the test chamber of any burning residue, as well as any traces of burning in the specimen holder and on the inner wall.

4 The air tightness of the gas circuit should be checked from time to time. Air leaks in the gas circuit can affect the test and can cause accidents.

5 The instrument is made of metal and is susceptible to rust over a long period of time. Keep the test environment dry and carry out regular anti-rust treatments.

Further questions about 45 Degree Flammability Tester TF310, please feel free to contact us:

Anastasia Hamilton –

Always get great quality at a low price, I am a regular customer.

Kay Sawyer –

Received everything and I am very pleased with the quality of the items as well as the perfect packaging.

Neil Ulysses –

I LOVE this machine. I was nervous whether the quality would be good enough but decided to give it a try anyway. This machine arrived unused and in perfect condition and was packaged well.

Herbert Lamb –

Received goods with thanks.The service is really thoughtful, pls keep it on !

Elvis Minnie –

It actually make me amazing!

Helen Bethune –

The machine has good performance in testing flammability of fabric.Really Worth it.

Omar Morley –

Perfect!Looking forward to the next cooperation.

Sid Adolph –

Great flammability tester.

Verna Yule –

great manufacturing!

Dennis Tout –

Love it. Will buy again from the 45 degree flammability tester suppiler.

Laura –

The actual 45° flammability tester is as beautiful as the image, accurate.

testextextile –

Thank you for your appreciation. Hope our service also satisfies you.

Jim –

Wonderful product, love it

testextextile –

Thank you very much

Bartholomew Dorothy –

Very accurate, and sensitive Instrument. Recommend!!!

Anonymous –

Works fine. the seller sent fast. I recommend to all.

Saxon Louisa –

The item arrived well thanks.