Influence of conventional finishing on fabric color Post-finishing is the last process of the…

How to Cope with the Problem of the Poor Color Fastness to Rubbing to Meet Customer Needs?

In the textile industry, printing and dyeing mills make cloth from grey cloth and then sell it to textile manufacturers such as garment factories. In this process, fabric quality testing is required, among which the failure of the poor color fastness to rubbing to meet customer needs is the most common problem as well as the most difficult to cope with.

Upon the receipt of the order by a printing and dyeing mill, it will purchase suitable grey cloth for printing and dyeing to pass the test in accordance with customer needs. The same is true for textile manufacturers. After receiving orders, they will purchase qualified fabrics to produce all kinds of textiles we usually use, and then put them into the market for sale after the test is passed.

If a printing and dyeing factory found that the color fastness to rubbing of the friction is poor and must be repaired after the production is completed. This thus will not only increase the production cost, delay of delivery, but also make it more difficult to improve the color fastness, and even waste fabrics, which brings great economic losses to the printing and dyeing mill. In the event of the failure of a textile manufacturer to find that the color fastness to rubbing does not meet the customer’s needs before the completion of the order, these products will either become waste products or be lucky enough to be distributed to the market, which will not only cause some problems in staining, and even do harm to human skin. Either way, the consequence is unbearable.

To solve the above problems, there are three key factors: printing and dyeing, testing, and rating. The problem of the color fastness to rubbing starts form the first factor, printing, and dyeing. Testing, as the standard and the specification, is needed provided that the color fastness to rubbing fails to meet customer needs, in other words, does not meet the quality requirements of textiles in various countries and regions. Objective rating provides a guarantee. Obviously, if there is something wrong with the rating, the replacement of superior quality products with shoddy ones and the deterioration of the rating will bring unnecessary interference to printing and testing. Much attention is hereinafter paid to these three factors.

The Influence of the Process of Printing and Dyeing on the Color Fastness to Rubbing

There are five parts in the process of printing and dyeing: selecting suitable dye, designing the process reasonably, choosing the auxiliary agent, testing hand samples after the test, and putting these samples into mass production. In order to avoid rework or fabric waste, it is necessary to test the sample repeatedly to determine the best production process.

In the process of printing and dyeing, the color fastness to rubbing of the fabric is determined by the amount of floating color, the molecular weight of the dye, the combination of the dye and fiber, the uniformity of dye penetration, and the particles of the dye on the fabric surface. For example, reactive dyes and fibers are fully connected to covalent bonding, whose color fastness to rubbing is high; But for insoluble azo dyes, when not treated appropriately, the dyes in part are in the form of insolubility, just sticking to the surface of fiber mechanically, in a low colour fastness to rubbing.

Therefore, for the purpose of good color fastness to rubbing, suitable dyes and proper process are indispensable for the full combination of dyes and fiber as well as the perfect permeation of dyes into fiber that ensures the former not remain the surface. If necessary, a smooth fixing agent can be added to make the dye bind to fiber more firmly to reduce the rubbing on the surface of the fabric where a soft film coated with dye is formed too so that the dye is not easy to fall off when being rubbed. As a result, its color fastness to rubbing is enhanced.

For more information, please refer to this article: Why do bulk production have color difference after customers have confirmed hand samples?

Attention in the Process of Testing the Colour Fastness to Rubbing

The test results of colour fastness to rubbing are a comprehensive reflection of the process from sampling, test operation to colour fastness rating. Only by relying on a high sense of responsibility and scientific, standard-compliant testing means and methods, and by doing well in every step to reduce human errors can the test results be more scientific and representative. Here some problems that should be paid attention to in the process of testing is further discussed.

1 Sampling and selection of rubbing cloth. The sampling shall be representative, like the sample shall be free from wrinkles and defects in appearance. Three samples are selected randomly from each batch of cloth for testing, two of which are qualified. Rubbing cloth should be made of standard cotton fabric to avoid the difference of test results caused by different structural components of rubbing cloth. The common samplers are as follows:

2 Conditions and test standards for test. The sample and rubbing cloth should be humidified in a lab conditioning chamber or in the standard atmosphere in which the test is carried out. I addition, we have to adopt corresponding test methods according to the different test standards given by customers so as to avoid any unnecessary work.

3 Before the test, the rubbing surface of the friction head should be carefully checked to see if it is smooth; otherwise, the stain on the rubbing cloth will show different depths inside and outside. Friction cloth fixed in the friction head must be firm, not loose; otherwise, the stained colour after being rubbed will not be round in shape. The rubbing surface of the friction head should always keep uniform contact with the sample. The improper installation of the friction head or any change in the thickness of the sample changes will bring about some transformation of the contact surface of the two, thus resulting in an uneven force on the sample, and affecting the test results.

4 The conformity of the pressure of the friction head on the sample to the regulations and in an unchanging state

There are three main elements that affect the degree of staining of rubbing cloth: the pressure of the friction head on the sample, the times of rubbing and speed of rubbing. For special instruments, the times and speed of rubbing keep generally stable, but the pressure on the surface of the sample changes with the change of the contact area between the friction head and the cloth surface, which affects the degree of staining. So, the speed and pressure of rubbing should be calibrated to ensure that the instrument meets the requirements of the standard.

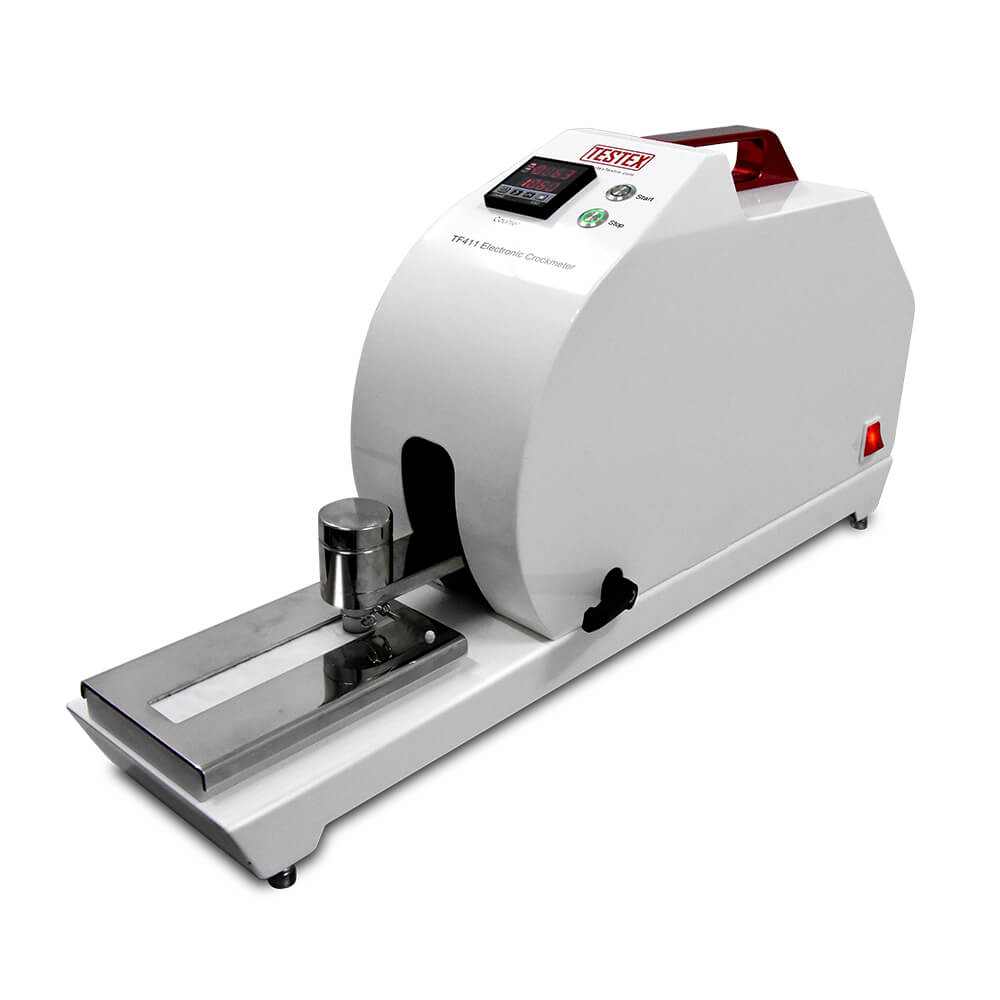

During the test, TESTEX’s tester for color fastness to rubbing is strongly recommended to prevent the test results from the above-mentioned elements, and TESTEX’s electric tester for color fastness to rubbing can avoid testing problems caused by unstable speed, frequency, and pressure of rubbing while guaranteeing a stable speed and pressure of rubbing.

Attention in the Colour Fastness Rating

When rating, the quality of the grey card, observation environment, light source, and other problems ought to exert influence on the observation. Therefore, after the rubbing test is conducted to the samples, the standard grey card must be used under the standard color light box for rating the samples to ensure the accuracy and objectivity of the test results. The following is an analysis of key points.

1 Proper Use and Preservation of grey card

Two points should be paid attention to in the use of gray card: first, keep the gray card clean and tidy, and it is forbidden to touch the surface of the gray card with hands when it is used; otherwise, it not only makes the rating incorrect but also forms some traces that are difficult to be removed to shorten the service life of the gray cards. Second, the gray card should be put into a protection bag after use, and a long time of exposure to sunlight should also be avoided. Please pay attention to keep the gray card in a dark and dry environment.

2 Observation angles

According to international standards, only two observation angles are available: one is the zero-degree light source, 45-degree observation, that is, the light source is illuminated vertically on the sample, and on the occasion of that, the observer can look at the sample from 45-degree. The second is a 45-degree light source. The inclined platform at 45-degree ensures that the light source irradiates the sample at 45 degrees (45°Fixed angle table) which provides observers an angle perpendicular to the surface of the sample for observation.

3 Location of sample

The sample to be tested should be placed in the middle of the light box as far as possible to reduce the influence of externally light source. Besides, In addition, when you need to compare the colour of two or more objects, you should place them side by side for comparison instead of overlapping them.

4 Environmental factors of colour matching

All externally light that has the opportunity to shine on the test sample must be avoided as far as possible. For example, the window in the field of vision should be covered with a grey curtain to make a dark room ideal for the use of the color light box. Another thing that is often overlooked is that none of the sundries are allowed to be placed in the color light box.

5 The capability of the instrument to test the metamerism effect

The so-called metamerism effect refers to the color of the samples is the same as required under one light source, but the color difference does not meet the requirements under another light source. All the equipment of light source for color matching must be equipped with two or more light sources to test the metamerism effect.

6 The requirement of light source switching

In observing the metamerism, if you want to switch the light source, it must be done in an instant, not like lighting lamp in daily life, bright only after a flash, which will irritate to eyes to affect the review results.

7 Record of the service time of the standard lamp

All standard light sources are produced from tubes, which usually need to be replaced if used for more than 2,000 hours or a year, so an accurate time recorder is a must.

How to cope with the problem of the failure of poor colour fastness to rubbing to meet customer needs? Through this article, I think you might have got some information. If you want to know more about color fastness testing, please contact us. As a professional supplier of textile instruments, we are committed to continually improve the user experience, TESTEX Textile Testing Equipment is a reliable choice for testing textile quality.

This Post Has 0 Comments