Coated fabric: It is a kind of fabric treated by special technology. It can…

The Sheets and Clothes Have Low Colour Fastness to Washing? Listen to What Professionals Say!

Textile fabric, such as bedsheets, clothes, etc., a lot of them will lose color after washing, some products fade seriously, even after washing many times, there will still be discolored. In life, there are a lot of complaints about the discolor of the textile:

“The water for washing the sheets was dyed red in the whole bucket, it was too serious.”

“One cloth has faded again, not only this dress can not be worn, but also the other clothes dyed can not be worn.”

“I bought a set of four-piece sets in the morning market, and when I bought, the merchant said that it wouldn’t fade, but when I washed five times after bought them, the water was dyed red and the sheets could not be used. Not only the mattress had been stained, but the child’s underwear had also been dyed. The bedsheet is not available and can’t be returned. It can only be left at home. ”

……

The loss color of textile is a common problem encountered by consumers, which is related to the color fastness of the textiles. In the use process of textile products with poor color fastness, the fabric is easy to fade, which affecting beauty, and even the exfoliated dye molecules or heavy metal ions may cause an allergic reaction to the skin, thereby endangering the health of the human body.

We have learned from the Textile Quality Supervision and Inspection Center that there may be two reasons for the unqualified color fastness: one is that the dye selection is incorrect, not according to the textile raw materials to choose the appropriate dye; the other is that the dyeing process is unreasonable, such as not choosing the appropriate dyeing time, heating rate and holding time, and so on. The label of textile on the bed is generally only content, specification, grade, manufacturer, etc. For consumers, it is not possible to assess the Color Fastness according to the appearance.

Therefore, both the manufacturers and sellers should test the Color Fastness grade of textiles according to the washing Color Fastness tester, and then control the quality of each batch of textiles strictly, only in this way can consumers rest assured. Today, TESTEX Team simply shares the basic knowledge of colour fastness test to washing with the majority of consumers.

Table of Contents

Test Preparation before Color Fastness to Washing

1 The principle of testing that you should know:

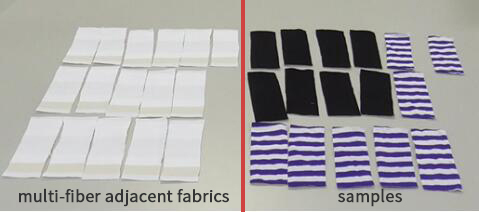

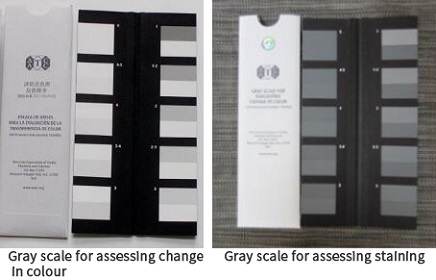

Stitch the sample with one or two pieces of specified multi-fiber adjacent fabric, which is placed in soap solution or other washing solution, mechanically stirred at the specified time and temperature, cleaned and dried. Taking the original sample as the reference sample, assess the discoloration of the sample by the left gray scale, and then assess the color stain of the adjacent fabric by the right gray scale.

2 What test standards are there?

Color fastness to washing is one of the common test items for textile dyeing fastness, which is mainly used to test the fastness of fabric clothing and home textile products after one or more times to simulate the dyeing after household washing and commercial washing. There are three common standard: AATCC 61, ISO 105 C06, GB/T 3921. The main differences are as follows: https://www.testextextile.com/contrast-of-test-methods-of-textile-color-fastness-to-washing/

3 Test equipment and materials to be prepared:

TF418 Washing fastness tester(Launderometer), TU300 Color light box

AATCC 1993 Standard Reference Detergent WOB or ECE

Gray scale for assessing change in colour, Gray scale for assessing staining

Corrosion resistant stainless steel beads

Multi-fiber adjacent fabric

Electronic balance, agitator

Distilled water or de-ionized water, etc.

Testing Process of Colour fastness to Washing

1 Samples Preparation: Place the samples and multi-fiber adjacent fabric under the constant temperature and humidity (temperature: 21±1℃, humidity: 65%±3%) for 4 hours. Cut 40mm*100mm specimen and multi-fiber adjacent fabric, and suture the specimen and multi-fiber adjacent fabric face to face along one short side. 2 Reagent Preparation: Prepare corresponding reagents according to different test standards and keep them as standby. If sodium perborate is required in the test, the preheating temperature shall not exceed 60℃ when preparing the solution, and it shall be used within 30 minutes at most to prevent the loss of oxidant. 3 Solution Warm-up: Put the specified volume of solution and a specified number of steel balls into the stainless steel cup, put the stainless steel cup into the launderometer for a few minutes, preheat to the specified temperature. Then put in the prepared sample for test. 4 Assessment Records: At the end of all tests, flush the samples twice with distilled water at 40℃, and then dry the samples in air not exceeding 60℃. After drying, assess the change in color of the sample and the stain of multi-fiber adjacent fabric under the color light box, and record the data sheet according to the requirements.Wash fastness is the most common test item for clothing textiles, which and crocking color fastness test are the two tests that are most prone to problems in textile materials. If you want to know more about the textile colour fastness test, please pay attention to TESTEX Blog.

This Post Has 0 Comments