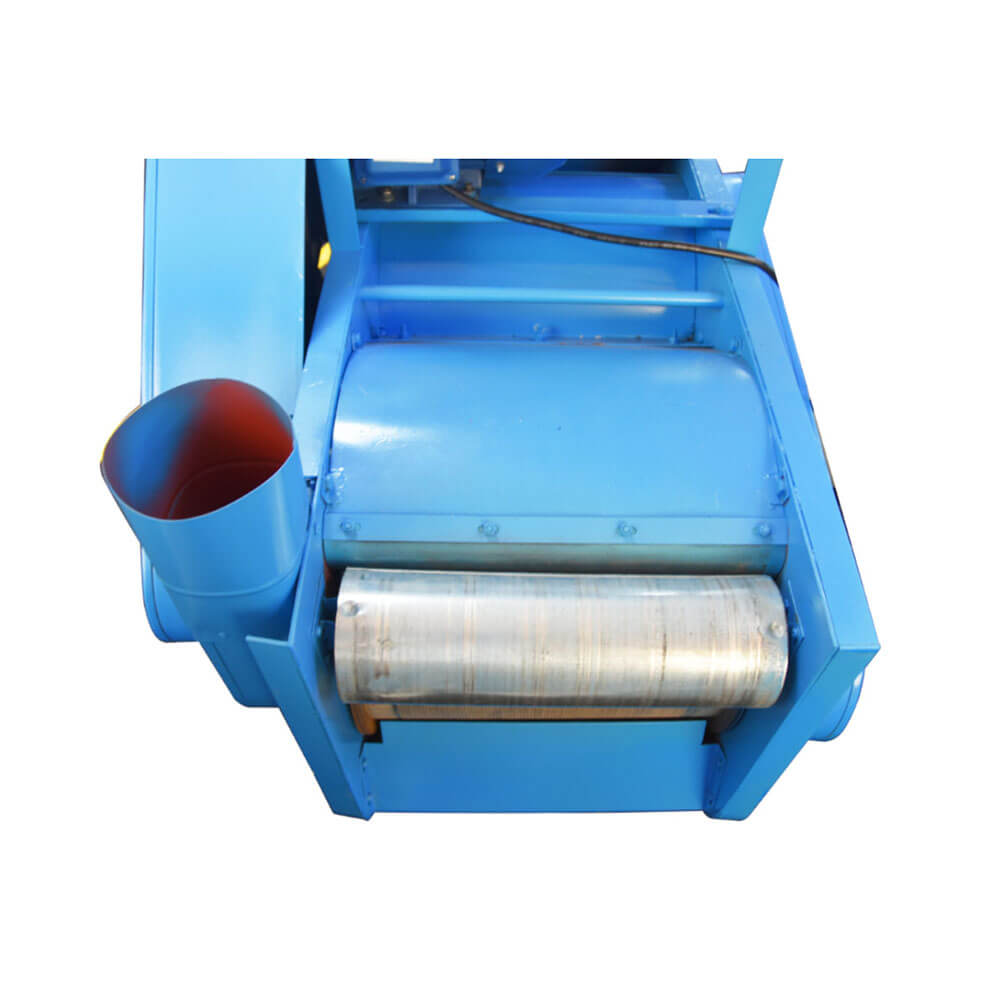

Sharp Edge Tester TT811

Sharp edge tester, also known as edge tester, edge-on-up sharpness tester, etc. Sharp edge tester determines whether accessible edges on toys or other products are likely to cause injury. Sharp edge tester test standards include ASTM F963 4.7, EN 71-1 8.11 16, CFR 1500.49, ISO 8124-1 5.8 and etc. We provide sharp edge tester for sale at a competitive price, please feel free to contact us.

Description

Application of Sharp Edge Tester

A sharp edge tester, which is a device that conducts sharp edge testing of products, can determine whether accessible edges on toys or other products have the potential to cause injury. By applying pressure-sensitive self-adhesive PTFE tape (simulating human skin) to a mandrel and then rotating it 360 degrees along the edge of the test. After completing the test, if the tape is cut in half or longer (approximately 13 mm), so the edge is determined to be dangerously sharp.

Besides, a sharp point tester will get the test done if your products have potential sharp points that need determination.

Features of Sharp Edge Tester

Reasonable design: equipped with a metal cabinet to ensure the durability of the instrument.

Very simple operation: the extended foot switch makes operation easier.

Accurate data: the external force adjustment function makes it very easy to adjust the actual force value to the displayed value, ensuring accuracy when calibrating the force value.

Included Accessories

- Power adapter

- Foot-switch

Optional Accessories

- Teflon Tape

Weight

| 5 kg |

Power/Air Source

| 220 V | 50 Hz |

Dimension

| Length: | 300 mm | Width: | 200 mm | Height: | 200 mm |

Standards

| ASTM F963 4.7 | EN 71-1 8.11 | 16 CFR 1500.49 | ISO 8124-1 5.8 |

| GB 6675 5.8 |

Why Choose TESTEX Horizontal Flammability Tester TF311

Strictly meet standards

All data for TT811 meet the standard parameters.

Consistency with international third-party laboratories

The test data are comparable to the test results obtained by well-known international third-party laboratories.

High repeatability

With both the same set of samples and the same machine, after multiple tests, the results will remain consistent.

High reproducibility

With both the same set of samples and different machines of the same model, after multiple tests, the results will remain consistent.

Longer service life

TESTEX makes prototypes and then subjects them to rigorous reliability testing in a variety of environments to ensure achieve the expected service life.

User-friendly transparent warranty policy

Textile testing machines, 14 months free warranty (12 months normal warranty time + 2 months shipping time). Besides, all spare parts, have 3 months free warranty.

We provide full life-cycle support for Sharp Edge Tester TT811. So feel free to contact our service team with any questions you may have.

Welcome to TESTEX – a professional textile testing instrument supplier – Sharp Edge Tester is on sale, contact us to get a detailed price quote.

1 review for Sharp Edge Tester TT811

You must be logged in to post a review.

Test significance

Toy sharp edge tester is used to test the sharp edge of children's toys, cars and other related products, and to assess whether the edge of toys has potential harm to children. Because the sharp edge specifications in different regions are not identical, there are sharp edge test ASTM that conform to ASTM sharp edges regulations, sharp edge test ISO that conform to ISO sharp edges regulations, etc., but the sharp edge test procedure is the same.

Test method

- Roll up a circle of TFE tape on the sharp edge tester test shaft with an overlap size of no more than 0.25 mm.

- Fix the sample so that the tested edges are immovable and bent.

- When the assembled toy can not be easily tested by touching the edge, the sample should be removed for testing, but if removed will affect its hardness, tools can be used to make it hard, but its supporting area should not be larger than that of the object being tested.

- Keep the angle is 90°±5 ° between the sharp point edge tester and the test edge.

- The contact point between the test edge and the gummed paper should be about the middle of the tape scheduling.

- The object being tested applies its least sharp position test.

- Adjust the sharp edge tester strength to 1.35LBS(6N).

- Apply force upward in the position of the rubber paper to make the light bright, while the test side end force is 1.35 LBS(6N).

- Start the sharp edge tester switch and rotate its axis around.

- Remove the gummed paper carefully not to expand its cutting size, measuring the length of the cutting.

Note

- The sharp edge tester calibration should be done before the test.

- The edge to be tested shall be the touchable edge of the toy component determined by the test.

- If the touchable edge of the toy as a whole cannot be tested, the toy's touchable edge should be removed for test separately.

- The key to sharp edge testing is how to fix the detected edge and ensure that the core axis is at a right angle to the edge and there is no relative motion between the shaft and the edge in the test.

- During the rotation of the core shaft, the pressure on the core shaft should be kept stable.

- For children under 36 months of age, sharp edges on toys are not allowed; for children aged 37 to 96 months, sharp edges may exist on toys, but warning notes are required.

As a professional supplier of textile testing instruments, please contact us if you want to know more about the sharp edge tester price, the detailed sharp edge tester manual, and so on.

[contact-form-7 id="16355" title="Inquiry"]

Lester III. –

Excellenct !!