Now, mask factories in European and American countries are facing some pressure: on the one…

How Helpful is a Edge Position Control System for the Mask Making Machine Debugging? Do not Multiply Entities beyond Necessity

In the mask production process, mask making machine debugging has always been a difficult point. In order to reduce the difficulty of debugging, some manufacturers have added a edge position control system to help debugging. However, whether the control system is practical is also a matter of great concern, after consulting many mask making machine debugging personnel, I came to the conclusion that: do not multiply entities beyond necessity, the edge position control system in the mask machine debugging is not too helpful. Now I will share some experience of the mask making machine debugging and the edge position control system application, I hope to help you.

Table of Contents

- ★ Mask making machine debugging

- ★ Will the edge position control system help with the mask making machine debugging?

- What is an edge position control system? The principle of the edge position control system.

- What problems can an edge position control system solve in the mask production?

- Factors affecting for the effectiveness of the edge position control system

- Possible problems caused by edge position control system

★ Mask making machine debugging

To find out whether a edge position control system is helpful for the debugging of mask making machine or not, we need to first briefly understand the basic principles and three stages of the mask making machine debugging.

The basic principle of debugging: by adjusting each unit, combine the non-woven fabric, nose bridge wires, and ear loops together in a certain order and structure to ensure the right mask size and the stability of production.

Stage 1: Preparation of the incoming material

With parts 1 and 2, the non-woven fabric is aligned and folded in preparation for the mask body.

With parts 3 and 4, the nose strip is drawn and stretched in preparation for cutting.

Stage 2: Making out the mask body

With 5, the aligned and folded nonwoven is initially shaped

With 6, cut the nose bridge wire and fed it into the non-woven in preparation for the hemming

With 7, the mask body is hemmed, second shaped, and prepared for cutting.

With 8, the mask production line is pulled forward

With 9 and 10, control the length of the mask body and cut the mask body off.

Stage 2 is the focus of the debugging and it will determine the size, hemming, and shaping of the mask body.

Stage 3: Cutting and welding of the ear loops

As the edge position control system no longer has an effect here, it will not be detailed here.

★ Will the edge position control system help with the mask making machine debugging?

What is an edge position control system? The principle of the edge position control system.

The edge position control system is mainly applied to the lateral deflection control of the coil material. Due to the limitation of equipment production and installation accuracy, the uniformity of the material itself is limited, which will produce the deflection phenomenon of material when closing or releasing the coil. The edge position control system can correct this deflection to a certain extent.

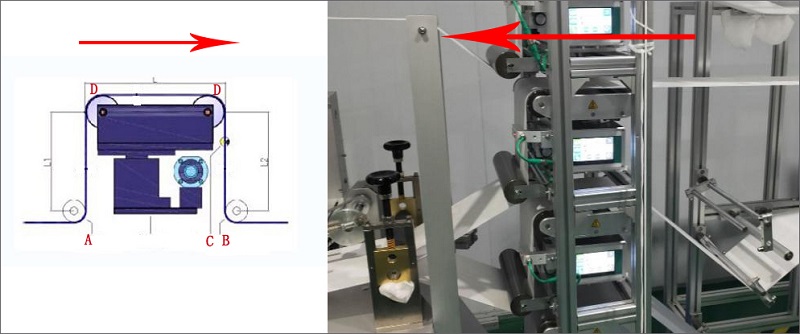

Diagram of the edge position control system

A is the deflection end, the fabric enters from end A. B is the fixed end, also the take-up roller, C is the sensor, the tension roller D is immobile, when the fabric is deflected, the tension roller generates a frictional force on the fabric with a deflection effect.

When sensor C detects a deflection of the fabric position, it sends a deflection signal to the controller. The controller in turn sends a calibration signal to the driver; the driver provides a calibrated speed to push the material in the opposite direction.

What problems can an edge position control system solve in the mask production?

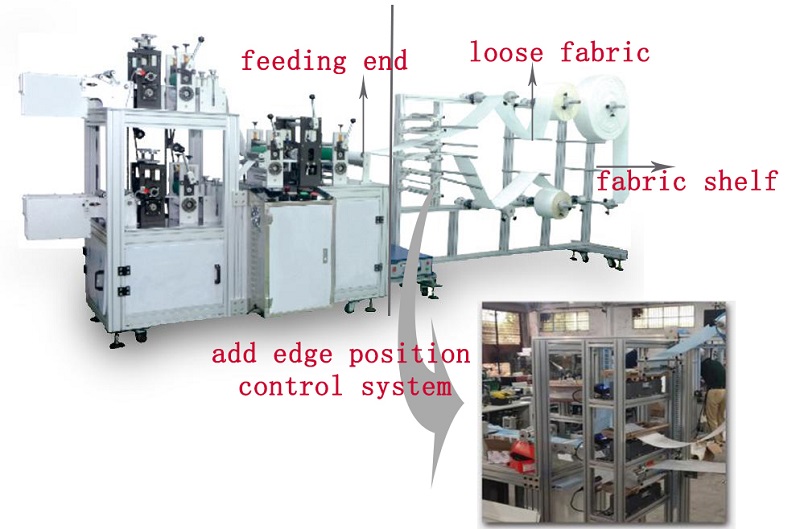

During mask production, due to the structural design (fabric shelf too large and too far from the feed end) of some mask making machines, it result the fabric often becomes loose during transfer, which is the main reason for the fabric position offset. Therefore, after the loosening and before feeding, we need to correct the fabric deflection, and so the edge position control system appears to correct the deflected fabric to the correct position.

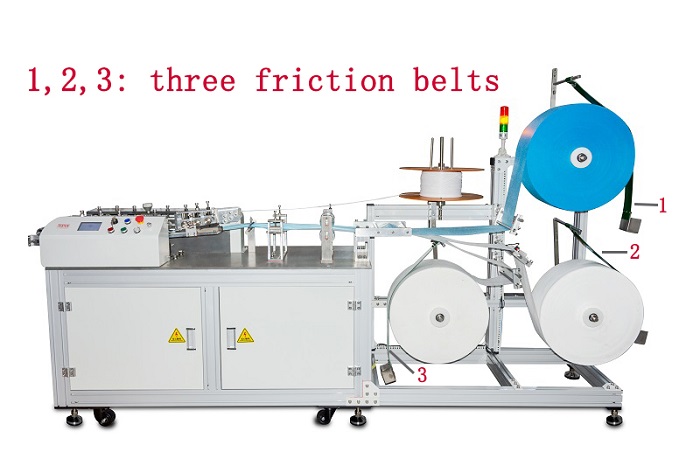

Let’s take a look at the structural design of this mask making machine above. The simple structure of the fabric shelf, which is very close to the feed end, coupled with the unique design of three friction belts, allows the fabric to be transferred forward at a balanced speed without loosening. In the actual production process, we have found that using this structural design of the mask making machine effectively avoids the phenomenon of material deflection and keeps the fabric tension stable during the use of a fabric roll, effectively avoiding secondary debugging.

Factors affecting for the effectiveness of the edge position control system

One veteran edge position control system supplier told us that one of the most common questions they will be asked is: “What is the accuracy of the edge position control system?” However, if you just get a simple answer such as “±3mm.” then this is irresponsible. This is because not enough information is provided here to determine the accuracy of the edge position control system and it is not possible to determine the final effect of the correction.

Asking about the accuracy based only on the design of the edge position control system, it is like asking how long a car can stop based only on the design of the car and tyre. We cannot answer this question accurately if we do not know the speed of the car and the condition of the road.

The accuracy of the edge position control system is the position accuracy of the material when it first comes out of the probe and which is determined by three factors: the deviation of the incoming material, the accuracy of the system itself and the install accuracy of the system. The edge position control system is usually installed upstream of the critical process and as close to it as possible in order to minimising position deviation when entering the critical process.

Possible problems caused by edge position control system

1 Lack of timely correction

The speed of the lateral movement is an important factor in the correct accuracy. In general, the faster the speed, the greater the difficulty in correcting the offset.

When the lateral position offset occurs in a very short time, we call this immediate position offset. This offset usually occurs when the length of the fabric is short or the speed is very high. This immediate position offset can also be caused by material, equipment, or process changes (e.g. sudden changes in tension). Because this position offset is immediate, the lateral speed of this position offset is infinite and the edge position control system cannot have an infinite tracking speed, therefore it is the most challenging position offset. For this immediate position offset, the edge position control system will have a deflection hysteresis.

2 Unstable deflection effect

In addition, the edge position control system can also cause fabric deflection. If the control circuit is not properly adjusted, if the blind spot of the probe is too large or if the driver has a loose/bouncing connection, then the system can cause the fabric deflection. There are various reasons for loose/bouncing driver: poor fit of the driver connections to the frame, axial micro-shift of the roller bearings, deformation of the deflector frame, etc. In addition, each type of edge position control system has several important installation criteria: alignment width, web winding angle, position of the centre of oscillation and direction of oscillation, etc. If the installation and design ignore the installation requirements of these factors, the system can cause fabric deflection and erratic control.

There is always a degree of looseness/bounce in the operation of an edge position control system, which creates two problems: it directly increases the output error of the system, and it destabilises the control loop, forcing it to reduce gain and further reducing the accuracy of the system. This places considerable demands on the installation of the system connections, which must be compact to avoid any loosening and bouncing.

Of course, there are other factors regarding the edge position control system: for example, what the limit range of the driver is, whether the starting push is sufficient and what the linear speed of the fabric is …… These all have an impact on the deflection effect. In addition, if purchase an edge position control system, which adds roughly 1m2 to the position, will increase the cost of transport and space.

In summary, if using the edge position control system for a mask making machine, you should consider not only the deflection capacity of the system, but also the characteristics of your nonwoven and the properties of the fabric movement on the machine. It is not very helpful compared to the problems that the edge position control system may cause, and we can solve the fabric deflection problem perfectly well with a modified design version of the APL 110 mask making machine.

This Post Has 0 Comments