Now, mask factories in European and American countries are facing some pressure: on the one…

3x Speed – the 250Pcs/min Mask Making Machine is Here

COVID-19 has been going on for roughly two years now. In the face mask market, from the initial shortage of supply to the current basic balance between supply and demand, it will be increasingly important to reduce costs and improve production efficiency for the mask manufacturers, which all depends on the production performance of the mask making machine.

Table of Contents

- ★ Supply and Demand Analysis of Face Mask Market

- ★ How to Improve Mask Production Efficiency and Reduce Production Costs?

- 1 No need to use a separate earloop welding machine, mask is formed in one time

- 2 Fast speed up to 250Pcs/min, making full use of the motor speed

- 3 The production of adult masks and child masks can be switched quickly

- 4 The interface of the mask making machine is intuitive and easy to understand, convenient to operate

- 5 The machine is stable, has few faults, and has a small floor space

- 6 After-sales service is more professional

★ Supply and Demand Analysis of Face Mask Market

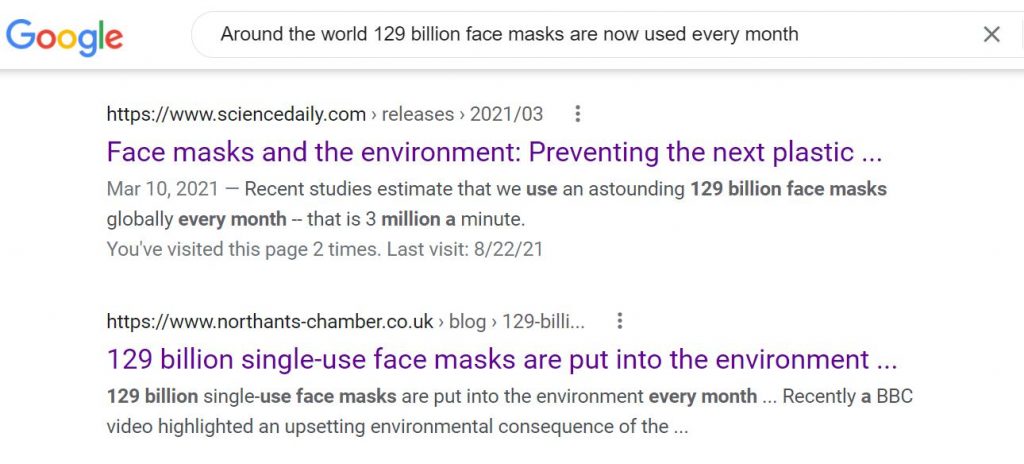

Before we analyse the mask machine, let’s take a look at some data on the global supply and demand of face masks.

It is estimated by relevant agencies that in the global mask market, 129 billion masks are used and discarded every month. Based on a 30-day month, an average of 3 million masks are used every minute, and 4.3 billion masks are used every day.

According to statistics, in early 2020, The top ten countries (China, USA, Japan, Korea, Germany, etc.) in global mask production have a combined daily production capacity of around 300 million masks. After the expansion of the global mask production line in 2020, the mask production capacity has been enhanced. Currently, there are no specific statistics out for the global production capacity in 2021, but even if the mask production capacity is enhanced 10 times, the daily production capacity is only 3 billion masks, which still cannot meet the daily demand of 4.3 billion masks. In addition, according to the assessment of relevant research institutions, the global demand for masks will level off in the next few years, and the market size will be about US$31.83 billion by 2027.

It is easy to see that the market demand for masks is still very large. Whether for manufacturers who have already established mask production lines or for those who want to build new mask production lines, if you want to establish a long-term advantage in mask production in such a large market, you must reduce mask production costs and improve mask production efficiency.

★ How to Improve Mask Production Efficiency and Reduce Production Costs?

We know that the efficiency and cost of mask production is mainly determined by the mask making machine. Below I will start from the mask making machine and give you an idea of what kind of mask making machine can meet the above requirements and what characteristics it has. Let’s take the TESTEX-APL250 mask making machine as an example.

1 No need to use a separate earloop welding machine, mask is formed in one time

The APL250 mask making machine has the advantage that the mask is formed in one time and which uses wide earloop, eliminates the need for a separate earloop welding machine and greatly simplifies the earloop welding process. The welding of the mask body and earloops is completed simultaneously, making the machine construction more rational and greatly increasing production efficiency.

2 Fast speed up to 250Pcs/min, making full use of the motor speed

As no separate earloop welding machine is used, the APL250 mask making machine is able to make full use of the speed of the motor. which, when combined with some edge position control system, allows for speeds of up to 250 pieces/min. Compared to a normal mask making machine with a speed of 80 pieces per minute, one is equivalent to three.

3 The production of adult masks and child masks can be switched quickly

Adult masks and child masks are of different sizes and for traditional mask making machines, it is either a case of using a different model of mask making machine or switching moulds and re-debugging the machine, which is often time consuming and cost prohibitive. The APL250 mask making machine, on the other hand, the production of adult masks and child masks can be switched quickly, greatly reducing production costs and making it possible to use one machine for two purposes.

4 The interface of the mask making machine is intuitive and easy to understand, convenient to operate

The APL250 mask making machine has a compact structure and a more user-friendly interface design, which is intuitive and easy to understand and operate, greatly reducing the difficulty of operation for staff and improving learning efficiency.

5 The machine is stable, has few faults, and has a small floor space

Each mask making machine of TESTEX is fully tested for stability before shipment to ensure that faults are minimized, which has been received full satisfaction by our customers. In addition, the APL250 mask making machine has a small floor space, with dimensions of 450cm * 115cm * 160cm (LxWxH), so you can build more mask production lines in the same space.

6 After-sales service is more professional

At TESTEX, we have professional debugging personnel, no matter which type of mask making machine you buy, there will be professional staff to answer your questions, in addition, the host, ultrasonic six months warranty (please consult our sales engineers for details)

In short, for the same quality, we have the best price, for the same price, we have the best quality. In addition, we have different types of mask making machines to target different standards and requirements, for example, our exclusive explosive model APL110 mask making machine, which has received unanimous praise from our customers, if you want to know more, please send us an email or call us.

This Post Has 0 Comments