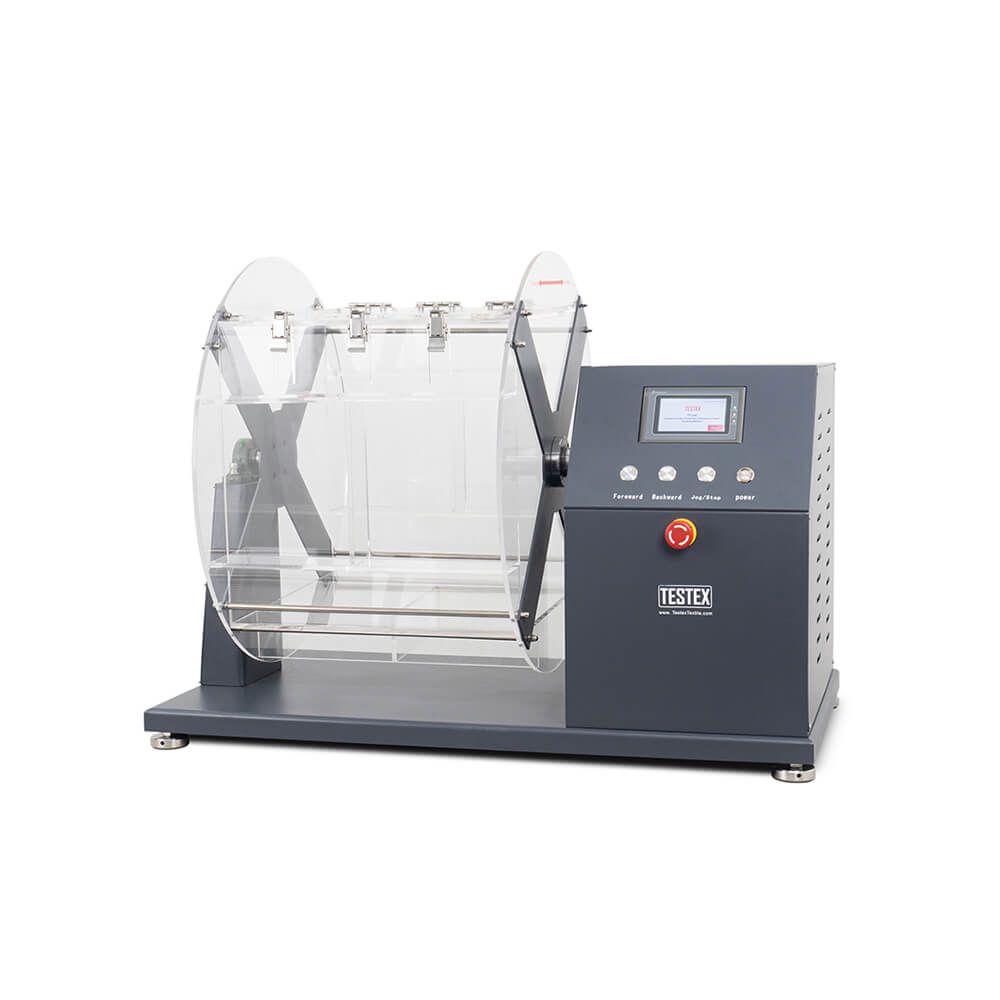

Spray Rating Tester TF160

Spray Rating Tester, to determine the surface wetting resistance of fabrics, which may or may not have been given a water-resistant or water-repellent finish. Spray Rating Tester complies with AATCC 22, ISO 4920, EN24920, etc. Our Spray Tester is your best choice when you do spray test.

Description

Application

Spray Rating Tester for testing the resistance performance of fabrics to surface wetting by water. Fabrics, which may or may not have been given a water-resistant or water-repellent finish, can be tested by this spray test method.

The spray rating tester consists of a metal frame. Through a nozzle, distilled water is sprayed onto the test sample 150 mm below. This water repellency tester is easy to use and gives consistent test results.

Specifications

- Nozzle 19 holes of Dia 0.86mm

- Angle of holder 45°

- Holder 150mm, 150mm below the nozzle

- Measuring Cup 250ml

Weight

| 5kg |

Dimensions

| Length: 360 mm | Width: 280 mm | Height: 510 mm |

Standards

| ISO 4920 | AATCC 22 GB/T4745 |

Test procedure

- As AATCC 22 required, we put the test piece to the humidifying treatment more than 4 hours, which under the environment of standard temperature of21±1℃and relative humility of 65±2℃.

- After the humidifying treatment, the test piece clamped by the holder on the support at a 45°, and we pure 50ml water into the funnel rapidly steadily in order to keep drenching constantly. When the water is used up, we can observe the test piece.

- According to description of spray rating to assess its grade of wet but without the intergrade.

Spray rating

- ISO 0 = AATCC 0: complete wetting of the entire face of the sample.

- ISO 1 = AATCC 50: complete wetting of the entire sample face beyond the spray points.

- ISO 2 = AATCC 70: partial wetting of the sample face beyond the spray points.

- ISO 3 = AATCC 80: wetting of specimen face at spray points.

- ISO 4 = AATCC 90: slight random sticking or wetting of the specimen face.

- ISO 5 = AATCC 100: no sticking or wetting of the specimen.

Test result

The test result should include the following message:

- The illustration of the test procedure according to the standard.

- Atmospheric conditions.

- Water temperature.

- Spray rating of each test piece.

- Experimental date.

Welcome to TESTEX – a professional textile testing instrument supplier – Spray Rating Tester is on sale, contact us to get a detailed price quote.