In this article, we will share with you the complete guide to Shrinkage Test…

Comprehensive Understanding about the Safety Performance of Textile Products

Table of Contents

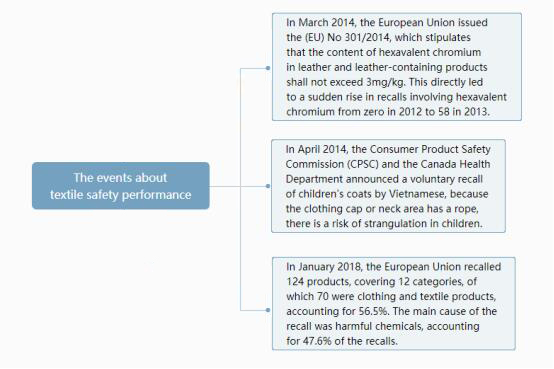

Why do you need to Improve the Safety Performance of Textile Products?

The above recall cases are being performed and will continue to be performed. The main reason is that most textile enterprises have not kept up with the changing trend of textiles both ideologically and technologically, and have not fully understood the evaluation requirements of textile safety performance.

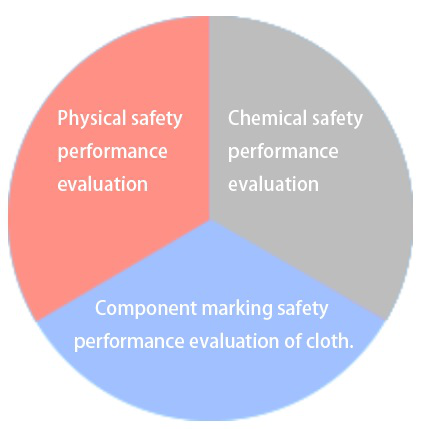

Understand the Evaluation Requirements of Textile Safety Performance

Three aspects of textile safety performance evaluation

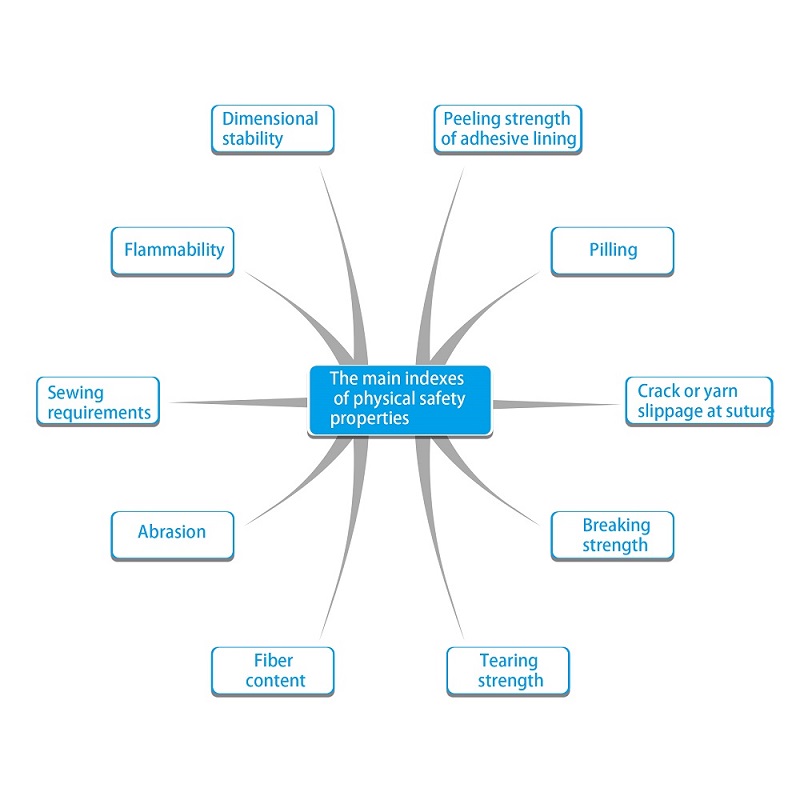

1 Physical safety performance evaluation of textiles

There are many corresponding regulations and standards, the following, there is some brief introduction to the corresponding regulations and standards for the three common important problems.

2 Chemical safety performance evaluation of textiles

At present, there are two most influential organizations: the Oeko-Tex Standard 100 and the European’s “Eco-label”, which can be used as a reference for textile chemical safety performance detection.

3 Component marking safety performance evaluation of cloth

For a long time, it is difficult to carry out the work smoothly to verify whether the marking of clothing component is correct or not. Therefore, the standard of the label of the textile label should be enforced in the form of legal text, which used to label component of all the household textiles such as fibers, yarns, fabrics and clothing products.

In 2013, Amazon, Leon max, Macy’s and Sears, were fined $1.26 million by the federal trade commission for misidentifying rayon as bamboo fiber, the heavy fine reflects that the determination of the U.S. Federal Trade Commission to deal with such matters seriously by the law.

The common regulations for evaluating the fiber component safety performance are as follows:

- EU Regulation: (EU) No 1007/2011

- U.S. Regulation: The Wool Products Labeling Act, 15 U.S.C. § 68; The Textile Products Identification Act, 15 U.S.C. § 70; 16 CFR Part 300 — Rules and Regulations under the Wool Products Labeling Act of 1939; 16 CFR Part 300 — Rules and Regulations under the Textile Fiber Products Identific Ation Act.

- China Compulsory Standard: GB 5296.1 — 2012 and GB 5396.4 — 2012

- Canada Regulation: Textile Labelling Act Textile Labelling and Advertising Regulations Guidance on Labelling Textile Articles Derived from Bamboo

- Australian regulation: Commerce (Trade Descriptions) Act 1905 Commerce (Imports) Regulations 1940

Development and Significance of Textile Safety Performance Testing

In recent years, there has great change for the textile safety performance demand in the world, many countries have established various regulations and decrees on harmful chemicals. The entire international textile market has gradually formed three key points of concern: safety issues, hazardous chemical conditions, and whether there is an eco-labelling.

With the increasing globalization of the textile industry and people’s attention to ecology and safety deepening, green barriers and quality and safety issues are becoming new trade barriers. The concepts of “green textile products” and “ecological textiles” have rapidly entered the field of international textile and clothing trade, and countries have put forward higher requirements for the “safety” of textiles and clothing in the using process. In this case, textile enterprises must enhance their competitiveness and keep up with the trend of the times in the fierce global competition, which is the significance of TESTEX Team‘s commitment to the research and development of textile testing instruments.

This Post Has 0 Comments