Welcome to our latest blog post, where we delve into the ever-evolving world of textile…

A new generation of intelligent Elmendorf tear tester technology–Automatic digital Elmendorf tear tester

Article Summary: This article discusses the development of Elmendorf tear tester technology in the 21st century, in the context of the rapid development of technology as mankind accelerates into the age of artificial intelligence. We will discuss the more advanced Elmendorf tear tester technology—Automatic digital Elmendorf tear tester.

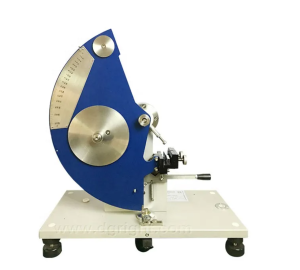

1 Introduction of what is Elmendorf tear tester

The Elmendorf method is a method of measuring the force required to cut a specified split in a thin, soft plastic sheet or film specimen to extend a specified length under specified loading conditions. Tear strength is usually determined using the Elmendorf method and the trouser tearing method.

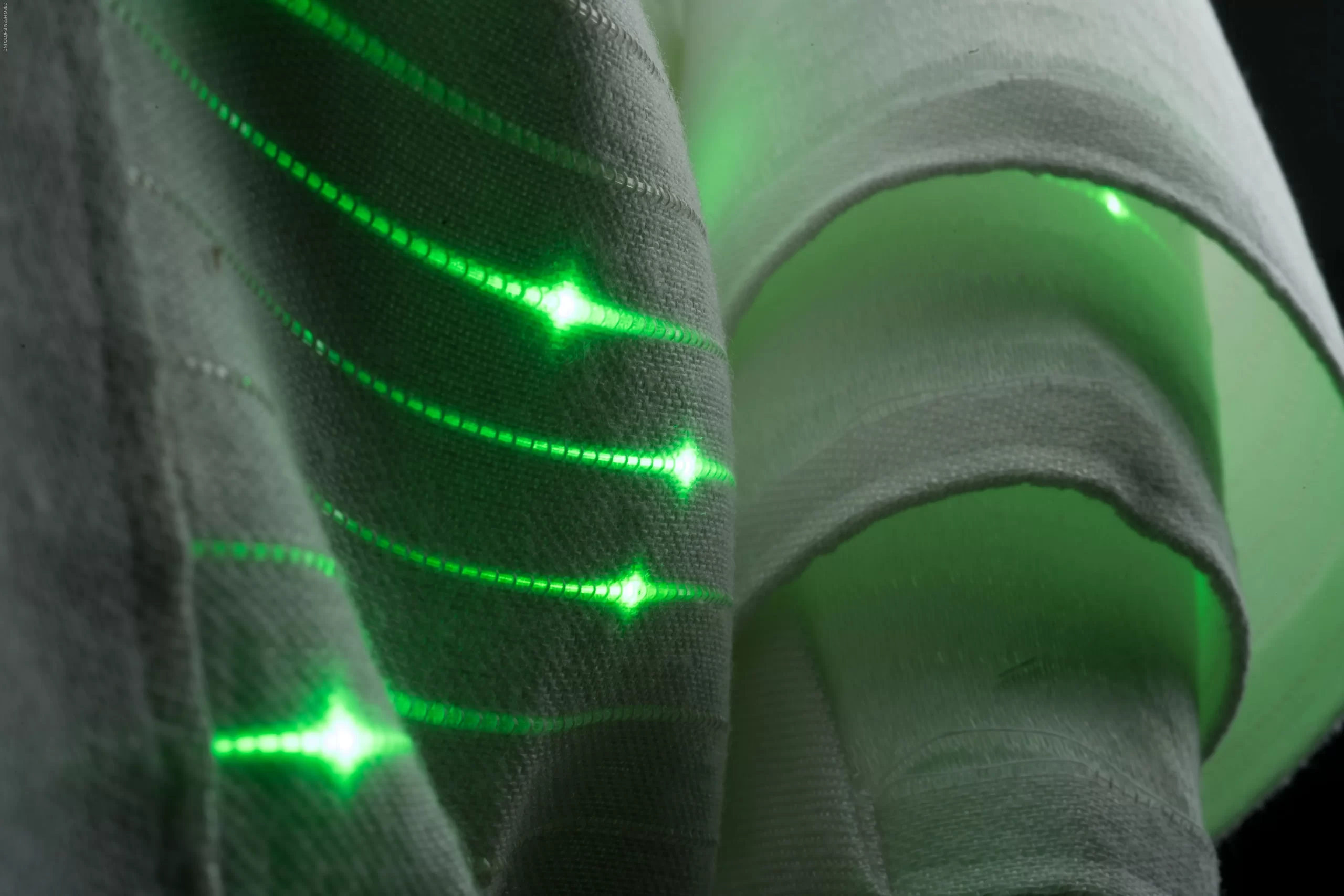

Tear strength (or Tear resistance)

Tear strength is the ability of a fabric to resist tearing or the force required for a tear to propagate once it has begun. Typically, the resistance offered by a textile material when subjected to a sudden force is often referred to as the tear strength. Tear strength is required for high performance applications as well as traditional textiles, i.e. industrial applications, ballistic jackets, tents, workwear jeans, sacks, aesthetic garments and many other applications. This is also important in technical textiles that perform heavy work. The high tear strength of textiles ensures that perforations in the fabric do not spread easily.

The formula of the tear strength test:

Mean tearing strength (gf) = K × mean value of scale reading / n

Where,

n = the number of test specimens tested together.

k = 16 without any augmenting weight for 1600 gf range.

k = 32 with any augmenting weight for 3200 gf range.

k = 64 with both augmenting weight for 6400 gf range.

2 . Applications of the Elmendorf tear tester

For the determination of the tear strength of various woven fabrics (Elmendorf method), for testing the impact tear strength of textiles, woven fabrics, nonwovens, coated fabrics, as well as for testing the tear strength of silk, cotton, various papers, cardboard and single and multi-layer corrugated cardboard.

Three testing methods

(1) Using the single seam tearing method, as the clamp moves up and down, the stressed yarns in the specimen begin to gradually separate up and down, and the yarns that are not directly stressed laterally begin to slide relative to the stressed yarns and gradually come together to form an approximate triangular area, which is usually called the stress triangle [7]. The size of the force triangle determines the size of the tearing force. The single seam method tears the yarn in a direction that is nearly perpendicular to the axial direction of the broken yarn, and the broken yarn is the one that is not directly stressed laterally.

(2) With the trapezoidal tearing method, one side of the specimen is in tension and the other side is in relaxation. In the trapezoidal method of tearing the direction of the pulling force is consistent with the axial direction of the broken yarn, or the direction of the pulling force is applied to the fabric at a small angle. In the trapezoidal tearing method, the straightening and deformation of the stressed yarn bear the role of tension, and the transverse yarn only plays the role of frictional resistance, and the broken yarn is the stressed and stretched yarn.

(3) The pendulum method of tearing is to measure the force required to tear a certain length of fabric by applying weights of different sizes, and it is to convert the maximum potential energy of the pendulum into the tearing force. When using the pendulum method to test the fabric tearing strength, note that the direction of the specimen yarn should be consistent with the short side of the specimen, which is conducive to the test process along the direction of the yarn to tear the specimen and not to tear off. This is important when the fabric is bowed. The pendulum tearing measurement range has its limitations, the maximum range of the ATLAS tearing strength tester is 64N and the maximum range of the James Heal tearing strength tester is 128N.

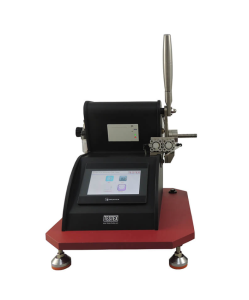

3 . Now the new generation of intelligent Elmendorf tear tester — Automatic digital Elmendorf tear tester

Technical features:

Digital Elmendorf tear tester

Compliant with standards:

ASTM D1424/D689, NEXT 17, M&S P29, BE EN ISO 13937/4674, BS 4468 DIN EN21974, GB/T 3917.1, ISO 1974

Scope of application:

Suitable for testing the tear resistance of textiles, nonwovens, paper, cardboard, films, woven materials, polymer films, etc.

The tear strength tester can test the force required to extend the specified length of a variety of sheet or film specimens under the specified load and the specified split using the Elmendorf tearing method. Tear strength can be tested at impact forces of 200-30,000 cN, with the impact force corresponding to a specific drop hammer. The instrument now cuts a small tongue-shaped opening in the specimen and then measures the tear strength as the opening expands. The instrument is designed for ease of use and flexibility, and can be used for a variety of tests on light and heavy specimens.

Instrument features:

(1). Double pendulum structure design to minimize resistance and provide higher testing accuracy

(2). Weighted base plate to prevent shaking, providing better test stability;

(3). Flexible double bullet clamping device design, easy and firm clamping specimens;

(4). Lightweight loading tool, heavy weights loading more easily

(5). Combination test weights to meet different test requirements, with a wide range of test ranges of 200N, 400N, 800cN, 1600cN, 3200cN, 6800cN, 13600cN and 30000cN, can meet the tear strength test of different materials such as fabric, paper, cardboard, plastic film, etc. The test units are MN, CN, N, G, KG, OZ, OZ, OZ, etc. LB optional

(6). Touch screen LCD interface is easy to operate. Safety pins lock the hammer at the beginning and end of the test to ensure operational safety

(7). With PC online interface, can be connected to PC, record and test results statistical analysis, with EXCEL form export function, can automatically print the test report

(8)Tear strength: The results are averaged for each test condition, for each test direction, and are accurate to 1% of the full scale of the instrument, in centiN (gravity) or 1 lb.

(9If required, calculate the standard deviation, and coefficient of variation.

(10)computer processing data: when the data is automatically processed by the computer, the calculation is generally generated by the software itself, the test results can be read directly from the computer and accurate to mN (gf). In any case, computer-processed data should be verified by the fabric of known results first, and the software program used to describe them in the report.

Technical parameters:

A. Microprocessor control;

B. For different thickness of the material, such as fabric, plastic, cardboard, etc., using a different weights of the hammer

C. Equipped with safety pins, weight loading tools, and safety guards to ensure the safety of the experiment

D. A variety of measurement units can be selected: including MN, CN, N, G, KG, OZ, LB

E. Blades with hardened coating, more sharp and durable;

F. Unique calibration system to ensure maximum test accuracy

Instrument preparation and calibration

1 Set the test range of the instrument to 20-80% or 20-60% of the full scale, and the clamp must be set according to A1.4.

Note 4: For standard test instruments, the effective test range is between 20 and 80%. For instruments with a large test range, the effective test range is 20-60%.

2 If the instrument is equipped with a sensor to display the force value, the entire sensor must be calibrated and care must be taken not to touch the sensor at will.

Once stained with dust or flying hair, vacuum cleaner can be used to suck dry.

3 Check whether the cutter is peak sharp and wear, and check whether the cutter is centered according to the requirements of A1.5-A1.7.

4 If pneumatic clamp is used, adjust the pressure to 55DkPa.

4.1 The maximum pressure of pneumatic clamp should not be higher than 620kPa and the minimum should not be less than 410kPa.

5 If computerized data collection system is used, please set the parameters according to the manufacturer’s instructions.

6 Check the scale of the selected pendulum within its full force range in accordance with the procedural requirements in Appendix A2, unless otherwise stated.

Test direction: The long side of the specimen is the test direction.

1 When cutting the specimen, when testing the woven direction (longitudinal, warp direction), take note of the specimen length direction parallel to the length direction of the cloth when taking the specimen; when testing perpendicular to the woven direction (transverse, weft direction), take note of the specimen length direction perpendicular to the length direction of the cloth when taking the specimen. And according to the sampling template and diagram (a or b) as described in 6.3, cut the specimen appropriately. If you need to test the wet state test, please take an extra sample at the dry state test sampling and leave it for the wet state test, and make corresponding records to keep the consistency of the sample as far as possible.

2 When testing woven fabrics, pay attention to the direction of the sample yarn should be consistent with the short side of the sample, so as to ensure that the pre-cut and the direction of the sample yarn parallel. This is conducive to the test along the direction of the yarn to tear the sample without tearing off. This is very important when the fabric has a bow slope.

3 When sampling, try to take samples at a certain distance apart and try to take samples along the diagonal. At the same time do not take samples within 1/10 of the side, in the hand sampling need to prevent folding, wrinkle, stain, water, etc..

Note 3: The tearing force of the fabric is directly related to the tearing length, so the size accuracy is important when preparing the specimen.

The traditional Elmendorf tear tester is only a mechanical measurement, which requires more manual operation to measure, and the accuracy of the measurement results is often affected by human factors. And the results are not easy to read and analyze. Therefore Testex has invested a lot of money and manpower in the development of the new generation of Elmendorf tear tester with an insight into the future of technology.

Technical insight and creative elite were developed by Bob-lu, an engineer employee of Testex. Bob-lu is a person who loves to learn and while reading the book “How Google Works”, he learned that Google always develops world-leading products because they have advanced technical insight and recruit creative elite from all over the world. Using this theory, Mr. Bob-lu applied it to the development of Testex’s next-generation Automatic digital Elmendorf tear tester.

Contact Testex for the Elmendorf tear tester price.

I believe that the new generation of intelligent Elmendorf tear tester can better help human beings to solve their problems. Testex started with such a concept, and with a higher technical insight to better help human beings to solve Elmendorf tear test problems, developed a new generation of Automatic digital Elmendorf tear tester. With a better microelectronic control system, Testex’s Automatic digital Elmendorf tear tester has greatly improved its ability to automatically test, calculate and analyze results, print test reports, and upload test data.

And it is equipped with an automatic correction function of pendulum friction damping to improve the measurement accuracy.

Testex also made a big improvement in Elmendorf Tearing Test software, they recruited a group of computer elites to develop Elmendorf Tearing Test software. This has made their Elmendorf Tearing Test software one of the best in the industry.

Testex has also adopted digital touch screen technology in their new generation instruments, which is leading the world. It allows you to use the Elmendorf tear tester like a cell phone or a tablet. very modern and technological, right?

Views on future technologies:

The development of the world textile industry is also the history of the development of textile product inspection technology, testing instruments, and equipment. Textile product inspection of intelligent, automated, is engaged in textile production and processing, quality inspection, instrument development, enterprise management, and marketing personnel will always be the pursuit. Textile testing instruments as an important means and tools for testing textile raw materials, semi-finished products, and finished products quality indicators, with the increase in the variety of textile materials, textile technology to improve and diversify the level of testing mechanisms, mechanical and automation technology advances, especially the development of microelectronics and computer technology, in recent decades, textile testing instruments in the testing mechanism, the level of mechatronics, microcomputers Application as well as test indicators and instrument varieties have made great progress, the emergence of a number of high-capacity, automated, intelligent, multi-functional mechatronics very high new instruments, textile testing instruments from the manual visual inspection, mechanical, mechanical and electrical, mechanical and electronic, to today’s mechatronics, began to step into a healthy development path. Catalyzed by the development of modern technology, as well as corporate culture, design concepts, and fierce competition in the same industry, the pursuit of profit maximization drive. The world of textile testing instruments and textile industry production equipment, as well as never stopping the pace of innovation and advancement, can be described as truly ever-changing. New textile testing instruments can be summarized as follows: First, focus on scientific and technological innovation, to promote revolutionary changes in the field of textile inspection; Second, the combination of computers, optics, information technology, and other high technology, and constantly improve the level of automation, inspection speed, accuracy, and reliability to greatly improve; Third, the product is gradually serialized and generalized, and continue to expand its use and scope of use.

This Post Has 0 Comments