Coated fabric: It is a kind of fabric treated by special technology. It can…

Application Research of Tensile Mechanical Properties of Geotextiles

In the tensile properties testing process of geotextiles, the elongation deformation is large, and the phenomenon of “necking” is easy to occur in the tensile process, and the width of the specimen has a great influence on the tensile strength index. Therefore, the tensile strength of geotextiles is an important index for testing and assessing the quality of geotextile products, and is an important basis for selecting geotextiles in engineering design.

As engineering materials, the use of geotextiles can simplify construction, improve project quality, reduce project costs, extend project life and reduce project maintenance. Geotextiles have been widely used in various engineering fields such as transportation, water conservancy, electric power, seaport, mining, rivers and lakes, coastal dams, soil and water conservation, and environmental pollution prevention.

Table of Contents

★ Classification, function, and application of geotextiles

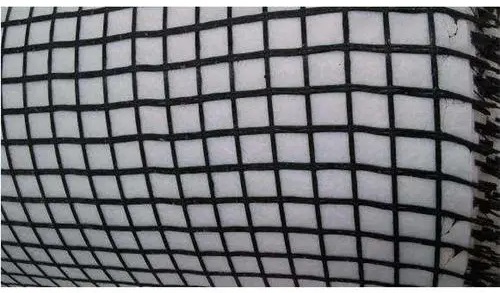

Geosynthetic materials are mainly divided into four categories: geotextiles, geomembranes, geocomposites, and geotechnical special materials, of which geotextiles include woven geotextiles, non-woven geotextiles, and knitted geotextiles according to the weaving method. In practical applications, geotextiles mainly have functions such as reinforcement, isolation, filtration, and drainage.

Reinforcement role and application

Geotextiles can limit the displacement of civil engineering works during long time use and can make the local stress acting on the soil transfer or distribute to a larger area, increase the frictional resistance between the soil and geotextiles, and play a reinforcing or strengthening role for civil engineering works, especially those on weak soil.

Mainly used in: highways, railroads, embankments, earth and rock dams, airports, sports fields, and other projects to strengthen weak foundations and also play a role in isolation and filtration. Temporary passage on wet areas, swamps, or compressible soils. Strengthen the stability of the slope of the heap or excavated steep slope. Increase the stability of the gravel slope and reinforced soil. Used as reinforcement in the backfill of retaining walls, reinforcing flexible pavement, repairing the road reflective cracks, etc.

Isolation role and application

Separate different soil structures with geotextiles to form a stable sub-interface, so that each layer can be separated and play its own characteristics and overall role according to the requirements. Separation with geotextiles can reduce the types of materials, save a lot of freight and reduce the cost of construction.

Mainly used in: the isolation layer between the surface and foundation of the highway, railroad, airport, parking lot, etc.; the isolation between railroad ballast and roadbed; the isolation between the roadbed and weak foundation; in the mixed earth and stone dam, the isolation between different dam building materials; the isolation between gabion, sandbag or soil bag and weak foundation; the isolation layer between artificial fill, rock pile, or material field and foundation; the isolation between different permafrost layers; river, river, lake The geotextile is placed underwater to play the role of isolation and also play the role of back filtration and reinforcement.

Filtration role and applications

Geotextiles allow water to pass through and effectively prevent soil particles from passing through, thus preventing the loss of soil particles and causing damage to the soil.

Mainly used in: the filter layer of clay core wall or clay inclined wall of earth and stone dam; the filter layer of various drainage bodies in earth and stone dam or embankment; the filter layer of the surface of ash storage dam or deposit dam; the filter layer of block stone or concrete slope protection of embankment, dam, river, canal, and coast; the filter layer of drainage system in the backfill of retaining wall; the filter layer around drainage culvert or around gravel drainage culvert; the filter layer of water well, pressure reducing well or inclined pressure pipe in water conservancy project.

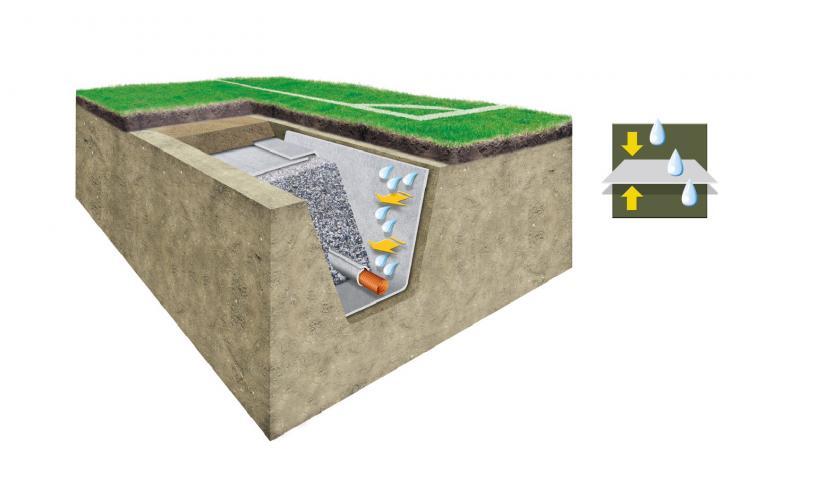

Drainage function and application

Geotextiles can form drainage channels in the soil, bringing together water in the soil and discharging it out of the body along the plane of the fabric.

Mainly used in vertical or horizontal drainage inside earth dams; drainage behind retaining walls; drainage around various buildings; dissipation of pore water pressure in buried soils; drainage of artificial fill foundations or sports field foundations, etc.

★ Research of tensile mechanical properties of geotextiles

Among the many applications of geotextiles, tensile strength (tensile strength) is the most basic and essential mechanical property index of geotextiles. Whether it is to give full play to the reinforcement, anti-slip, pulling function of geotextiles, or for soft foundation reinforcement, matting, seepage control, shore protection, isolation, drainage, and other applications, in order to ensure the realization of the function, geotextiles are required to have a certain tensile strength. Therefore, how to correctly determine and predict the tensile strength of geotextiles is an important issue in the study of geotextiles.

Research on the width of specimens for strip tensile test of geotextiles

Usually, the determination of tensile strength of geotextiles still follows the strip tensile test method of textiles. For geotextiles, especially non-woven geotextiles, tensile deformation is very large when pulled, the middle of the specimen will occur lateral shrinkage, that is, the “necking” phenomenon, the test results of tensile strength will be low. In order to make the test results as close as possible to the actual situation, the standing method reduces the “necking” effect. One method is to clamp the specimen with a convex nail between the two jigs to prevent lateral shrinkage during stretching and avoid “necking”, but it is more troublesome. Another method is to widen the specimen. At present, the conventional tensile test more often uses wide specimens to reduce the impact of “necking”.

In the standards specimens for textile and geotextile tensile, ordinary textile specimens are narrow and long, generally 50mm wide and 75~200mm long; while geotextile specimens are wide and short, generally 100mm long, 200mm wide, and 500mm wide. Usually the width of 50mm tensile specimens called narrow; will be 200mm wide specimens called wide; width of 500mm specimens called extra-wide specimens.

For geotextiles, most of the international tendency is to use 200mm wide samples, such as ASTM D4595 “Standard Test Method for Tensile Properties of Geotextiles by the Wide-Width Strip Method”. France and Italy have recommended the use of 500mm wide specimens. The practice has proved that the specimen is too wide, difficult to operate, and there are problems with the specimen being fixed. China’s National Bureau of Quality and Technical Supervision with reference to international standards for geotextiles and geosynthetics product standards GB/T 15788 is the standard for geotextiles tensile test wide strip method, which stipulates that the width of the specimen is 200mm.

The theory is that the change in width and length of the specimen causes a change in necking when the specimen is stretched, which affects the tensile strength of the specimen. The smaller the width to length ratio of the specimen, the smaller the necking and the higher the tensile strength. In 1980, Bell and Hichs concluded from their test that for woven fabrics, the effect of strip width on breaking strength decreases after the strip width to length ratio exceeds 1:1, while for nonwoven fabrics, the effect of strip width on breaking strength decreases after the strip width to length ratio exceeds 4:1. In addition, the effect of sample width on tensile strength of needle-punched nonwoven geotextiles has the effect of “edge”. Increasing the width of the specimen helps to reduce the effect of the “edge” effect and increase the fracture strength.

In 1986, B. Myle provided more representative information to the Third International Conference on Geotextiles. They stretched high-strength woven geotextiles and lightweight nonwoven geotextiles with widths of 50mm, 200mm, 500mm, and 1000mm respectively, and concluded that the change in strength was not significant when the width of the specimen was greater than 500mm. If the 1000mm wide specimen as a benchmark, the tensile strength measured with a 50mm wide woven narrow strip specimen will be 13% higher, while the tensile strength of non-woven geotextiles affected by lateral shrinkage is 30% lower. As the lateral necking of woven fabrics after being pulled is not obvious, and the narrower the specimen the smaller the uneven rate, the tensile properties of narrow specimens will be biased high by the influence of uneven rate.

Some researchers have also concluded from tests on specimens of different widths that specimens with a width of less than 200mm will overestimate the ultimate tensile strength of woven geotextiles and geogrids by up to about 20%; for nonwoven fabric specimens with a greater degree of necking in the stretching process, it is recommended that the width of the specimen be increased appropriately or that some technical corrections be made to the value obtained from the 50mm specimen; as the width of the specimen increases, the tensile strength tends to a stable value.

Tensile strength research on geotextile breakage and open-hole geotextiles

When geotextiles are actually used in engineering, they are often punctured or broken due to different structure shapes or construction needs to open holes in appropriate parts, or affected by engineering conditions. The strength of the geotextile is determined by its own structural condition, and when its structure itself is mechanically damaged or opened, its strength will inevitably be affected.

Kan and Chan simulated damage in real applications by artificially opening holes in the nonwoven geotextiles. Tensile tests were performed using 50mm and 100mm wide specimens. The parameters studied included the number of holes, the location of the holes, the elongation, and the tensile direction of the specimens. A mathematical model was also developed to characterize the tensile properties of the geotextiles using a multiple linear regression curve fitting technique. The data showed that the specimen width had an effect on the tensile strength. The tensile strength and elongation of the specimens decreased when the number of holes increased or the direction of the holes was perpendicular to the tensile direction.

Chi et al. tested the tensile strength of 200mmx100mm nonwoven geotextile specimens by opening rectangular, square and circular holes, and also compared the tensile strength of the remaining width after opening with that of the original specimen. The test analysis research concludes: specimen open hole area gradually increases, the tensile strength gradually decreases, and a linear relationship; damage occurs in the stress concentration point; open hole after the fabric tensile strength depends on the specimen stress width, the greater the stress width, the greater the tensile strength; fabric regardless of what type of hole, due to the role of stress concentration, the remaining width of the fabric strength value is slightly smaller than the equal width without open hole; fabric open hole The tensile strength of the fabric is reduced by a percentage greater than the area reduction percentage.

Qian used the boundary element method to analyze the stress concentration near the hole of the 100mm wide specimen of composite geotextile when opening a circular hole. The maximum stress value near the hole in the specimen increases as the size of the circular hole increases when the specimen is subjected to unidirectional and bidirectional tension with a certain size.

Research on other tensile aspects of geotextiles

For the study of tensile mechanical properties of geotextiles, more studies are related to one-way stretching. The study of strip tensile test specimen width and the study of breakage and open hole tensile described above are also basically studied on the basis of unidirectional stretching of geotextiles.

Since the force of geotextiles in the actual use process is very complex, only the study of its one-way tensile is not enough. The study of bidirectional tensile properties of geotextiles used in engineering should have more practical application value.

Bais investigated the bi-directional stretching of spunbond nonwoven geotextiles. The theoretical model was established by analyzing the stress-strain curve and orientation distribution of the fibers. The nonlinearity of the fibers was considered in the model, but it was limited to the case of bi-directional stretching of the strip with zero transverse strain, and the theoretical prediction results in the small deformation range were in good agreement with the test.

In addition to studying the tensile mechanical properties of geotextiles themselves, many researchers have also studied the properties of geotextiles in practical applications in interaction with the soil. For example, Mogahzy studied the interaction between soil and geotextiles and proposed three forms of damage when geotextiles are subjected to tensile action in soil, and also established a general equation to calculate the critical coefficient of geotextile-soil interaction and explained it theoretically.

In the practical application of geotextiles, tensile properties are crucial. This paper discusses theoretically that the tensile mechanical properties of geotextiles are of great significance to their practical engineering applications, and hopes to provide a solid theoretical basis for the practical application of geotextiles.

This Post Has 0 Comments