In this article, we will share with you the complete guide to Shrinkage Test…

What is the Textile Fabric Testing, Test Method, Test Item Classification

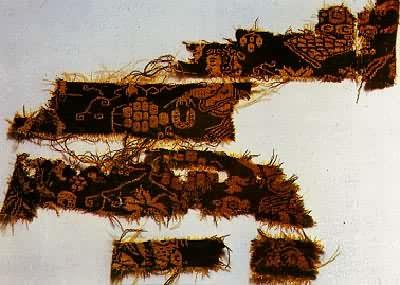

Introduction: The human use the textiles (materials made of fibers) with different forms has been used for thousands of years, and the earliest records of textiles are traced back to fabrics, baskets, and nets on small ceramic tablets 27,000 years ago. Now, textiles have been applied to various industries, and our life is already inseparable from textiles, so the testing industry for textiles has emerged.

What is Textile Testing? Why do you need Textile Testing? The Purpose and Significance of Textile Testing.

Textile testing is a scientific test technique and method to evaluate whether the quality of textiles meets the requirements of the specified standards. Based on the use and conditions of textiles, we analyze and study the influence on the product by the composition, structure, and properties of textiles, and determine the use value of textiles.

When using textile products, you must hope that they have a good touch, good appreciation, durability, and should not contain harmful substances. But how should we ensure that textiles meet the demand? Through the analysis, test, evaluation and comparison of the physical and chemical properties of textiles, we comprehensively study the factors related to textile quality and the relationship between these factors, from which the most important quality information can be obtained, so as to improve the quality of textiles and fully meet the needs of consumers under the most economical conditions.

The main purpose and significance of textile testing are:

To check the quality and suitability of raw material

To monitor the production (process control)

To assess the quality of the final product

To investigate the faulty materials

To set standards or benchmarks

For research and development purpose

For new product development

Basic Conditions and Method of Textile Testing

1 First of all, we should understand the test purpose and determine the test standards.

For textile testing, we should understand the standard requirements of customers and test at the beginning of proofing, so as not to find unqualified after mass production, resulting in a large number of rework and even waste of resources. For textile research and development, standard setting, we need to formulate the test variables, test one by one, find out the factors that affect the quality of textiles, so as to guide the production.

2 Sample preparation stage

Sampling, humidification, pretreatment (washing, drying), cutting samples; adjusting test environment. This step is to reduce the impact of external factors on the test, to ensure the repeatability of textile testing.

3 Test stage

Select the machine (must be calibrated before the test)

Start the test

Record test data

Restore machine (machine parameters, switching power supply, test hygiene)

Tidy up the test samples (be classified and put away)

In this step, it is necessary to reduce the operation error and avoid the test error caused by human factors. So the experience of the operator is very important.

4 Test report

According to the standard, see if the tested sample is evaluated.

Analyze and sort out the data and get the test results.

Prepare test report and file it.

Classification of Textile Testing Items

1 Classification according to the textile application

From fiber to yarn, from yarn to fabric, from fabric to textile finished product, every step of the textile product production process cannot be separated from testing.

For example, fiber testing mainly includes fiber content & fineness analysis, Micronaire value test, fiber length, fiber strength test and so on. Yarn testing mainly includes yarn twist, yarn density, yarn strength, yarn winder and so on.

Fabrics and textile products are the most widely used, and there are many test items. Common textile products are wearing textiles, household textiles, medical textiles, industrial textiles, military textiles, and arts & crafts textiles and so on. These products have different testing items because of different application, such as apparel testing pays attention to comfort and color fastness test; bandages, gauze and another medical textile testing will pay attention to safety and permeability testing; safety clothing will pay attention to fire resistance test and so on.

2 Classification according to textile test standards

International Standards: ISO, IEC, GATT

Regional standards: CEN, CENEL, ASAC, PASC, ARSO

Chinese National Standard: GB/FZ

American National Standard: ASTM

American Association of Dyeing and Chemical Authors: AATCC

EU Standards: EN

Japanese Industrial Standards: JIS

Australian National Standards: AS

British National Standards: BS

French Standards: NF

German Standard: DIN

Korean Industrial Standard: KS

3 Classification according to textile property

The common properties of textiles include the appearance and preservation of textiles, the durability of textiles (also known as mechanical properties), the safety properties of textiles, and the comfort properties of textiles.

The appearance test of textiles mainly includes the appearance defects and surface smoothness of textiles, the color difference and color fastness of textiles, the pilling property of textiles, the snagging property, stiffness, drape and wrinkle recovery of textiles, and so on.

The durability test of textiles mainly includes the tensile fracture characteristics of the fabric, the tear characteristics of the fabric, the abrasion properties of the fabric, the dimensional stability and so on.

The safety performance test of textiles mainly includes PH value test, flame resistance, antistatic property, formaldehyde content, mildew resistance, antibacterial resistance, contamination resistance and so on.

The comfort test of textiles mainly includes thermal conductivity, moisture permeability, air permeability, waterproof and so on.

In addition, in the whole textile testing industry, the selection of accessories, consumables should also meet the standards, common consumables are lined, color cards, detergents, accompanied cloth, blue standard, sample photos and so on, if you want to build your own testing laboratory, obtain testing qualifications, then these consumables are essential.

TESTEX has developed a variety of textile testing instruments and consumables, which can be changed according to the application requirements. TESTEX textile testing instruments are guaranteed to meet corresponding standards and completely tested to ensure the highest performance and longer life.

This Post Has One Comment

Leave a Reply

You must be logged in to post a comment.

Hello,

I am looking to test some silicon ripstop nylon for its strength and heat resistance. I am looking to find out at what temperature it can be heated to before it starts to cause damage to the fabric and how much pressure the fabric can withstand being pulled apart. Basically a grab test.

Is this something you can do for me if I provide the fabric?

I look forward to hearing from you

With thanks

Hugo