Each season's trendy colors have a positive effect on market consumption to a certain…

Fabric Pilling: What to Know, Do and Expect, The Complete Guide

Fabric pilling, is a common phenomena happened on many fabrics or clothes, in this article, we try to cover the most complete aspects about fabric pilling, below is the content, if you are already having a solid knowledge on topics like fabric pilling definition(aka. what’s pilling), you can jump into the chapter which you find interested most, enjoy!

Fabric Pilling Content:

Table of Contents

- Foreword

- CHAPTER 1: FABRIC PILLING AS A CONCEPT, FABRIC PILLING DEFINITION

- CHAPTER 2: PHASES IN WHICH FABRIC PILLING OCCURS

- CHAPTER 3: PRODUCER AND CONSUMER VIEWS ON WHY FABRIC PILLING HAPPENS

- CHAPTER 4: POPULAR, EASY-TO-PILL FABRICS TO WATCH OUT FOR

- CHAPTER 5: SOLUTIONS TO FABRIC PILLING

- CHAPTER 6: CONTEMPORARY METHODS OF DETECTING FABRIC PILLING AND HOW THEY WORK

- CHAPTER 7: CONCLUSION

Foreword

The constant development the world has seen has uplifted the standard of living for man. Clothes are not just needed for warmth anymore, but for their aesthetic purposes and the fulfillment of fashion trends. That is to say, in our world, clothing is expected to pass the sturdiness and reliability tests and also provide comfort and the beautification of its host. Some fabrics pill easily, fabric pilling, causing fast wear and tear when they aren’t selected and chosen right. Fabric pilling degrades the appearance of clothing and reduces the durability and reliability of the cloth.

CHAPTER 1: FABRIC PILLING AS A CONCEPT, FABRIC PILLING DEFINITION

A pill is a small ball that forms on the surface of a cloth. They could be a bobble, fuzzball, or lint ball that appears on clothes whose quality has degraded due to usage. Fabric pilling is caused by wear and tear and is a facial and surface defect of fabric that is easily seen and damages the aesthetic function of clothing. The usage of clothes, the washing of clothes, its constant exposure to light, air, and weather are some of the few reasons why fabric pilling happens. When fibers loosen, they begin to push out treads to the surface, thereby breeding abrasion and causing fabric pilling. It is worthy to note that the balls (pills) seen on the surface of the fabric are fibers that haven’t broken but protrude through the stretching and loosening of the material. The logical corollary here is, fabric pilling occurs on the part that receives the most abrasion examples of these are the collars, the cuffs, the thighs, and, in most cases, the rear parts of trousers.

Fabric pilling isn’t the ultimate death and does not need to put an end to the use of clothing. Fabric Pilling can be removed from cloth (by fabric pilling remover), more so some fabrics are less likely to pill than others. In clear terms, fabric pilling occurs at different levels, and this is largely dependent on some factors. The clothing industry states that fabric pilling occurs in four phases; generation of fuzz, entanglement, growth, and then finally wear off.

CHAPTER 2: PHASES IN WHICH FABRIC PILLING OCCURS

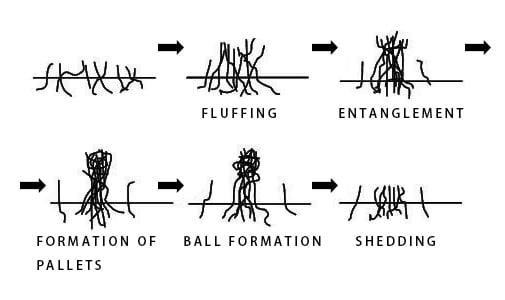

Fabric pilling occurs in the same conventional phases it has always been. It’s a constant process that happens in phases.

(A) Zero phase of fabric pilling:

- Fabric is as it is, with hairiness on the surface and basically new.

(B) First phase of fabric pilling: Fluffing

- Due to continuous friction, the cotton fibers are drawn from the cloth to create fur.

(C) Second phase of fabric pilling: Entanglement

- The fibers that have not broken off are entangled, which intensifies the stretching of the fibers.

(D) Third phase of fabric pilling: Formation of pallets

- The fibers are entangled continuously, causing pellets formation.

(E) Fourth phase of fabric pilling: Ball formation

- The fibers connecting the pellets are broken and drawn, leading to the formation of balls.

(F) Fifth phase of fabric pilling: Shedding

- Balls formed are shed in this stage.

Fabric Pilling Process Image, As shown below:

The main process phases of fabric pilling is further explained below:

Fluff phase of fabric pilling:

Fluffing occurs when the friction affecting the fabric is far greater than the strength and capacity of the fabric on which it acts. Fluffing can also occur when there is cohesion between fibers, which often happens during washing. In this fabric pilling state, the fibers are pulled, forming loops and fluffs on the surface of the fabric. Fluffs are formed on the longitudinal direction, and they make the surface lose its luster.

Entanglement phase of fabric pilling:

When fabric fluff to a certain degree of length, they get exposed to actions such as rubbing, friction, and this creates some form of entanglement. In dense pill areas, the fabrics are likely to tangle more than areas with less pilling. The balls formed from the entanglement phase easily hide dirt, and this is because they are formed with such a meticulous process. One end of the ball remains embedded in the fibers and connected to the surface. This affects the aesthetic purpose of such fabric. Pallet formation occurs in this fabric pilling phase.

Ball formation phase of fabric pilling:

Entangled fibers eventually form balls that are visceral on the surface of the fabric. These accumulate dust and dirt on the surface of the fabric. In some cases, research has shown they start to affect and make surrounding fabric pill due to their ability to increase friction.

Shedding phase of fabric pilling:

Shedding is the final phase of fabric pilling. This occurs when the fabric connected to the ball keeps on stretching, thereby leading to a break due to fatigue. These balls eventually fall off the surface of the fabric. Fabrics in their appearance can be deceiving, leading people to believe that they won’t pill early but this, in most cases, isn’t true.

These pills then become very noticeable and undesirable look on our fabrics and wears. With the brief explanation of what pilling in a fabric means, it is very important to note that pilling in a fabric can be removed and that there are some fabrics that are less likely to pill, i.e less chance to generate fabric pilling.

CHAPTER 3: PRODUCER AND CONSUMER VIEWS ON WHY FABRIC PILLING HAPPENS

Why do fabrics pill, or the reason of fabric pilling?

Fabric pilling is the result of the continuous receipt of forces and human-made actions on fabrics. It is caused by friction, cohesion, washing, amongst other actions. When fibers get loose due to these continuous actions, they start to fluff, entangle, form balls, and eventually fall off through shedding. This phenomenon in which the fibers in fabric go from being revealed on the surface to forming pallets and breaking off is known as fabric pilling.

Fabric pilling affects the aesthetic function of cloth and reduces its reliability and durability. The need to study the causes and reasons why this phenomenon exists is very important not only to the consumer, marketers, or producers but to the textile industry at large. The conclusive result here forms a guide to how textiles are created and formed.

3.1 Four major fabric pilling driving factors; Manufacturers view

Explained below are a manufacturer view on the factors driving fabric pilling and how they play out in terms of fiber, dyeing of fabric, finishing, and yarn.

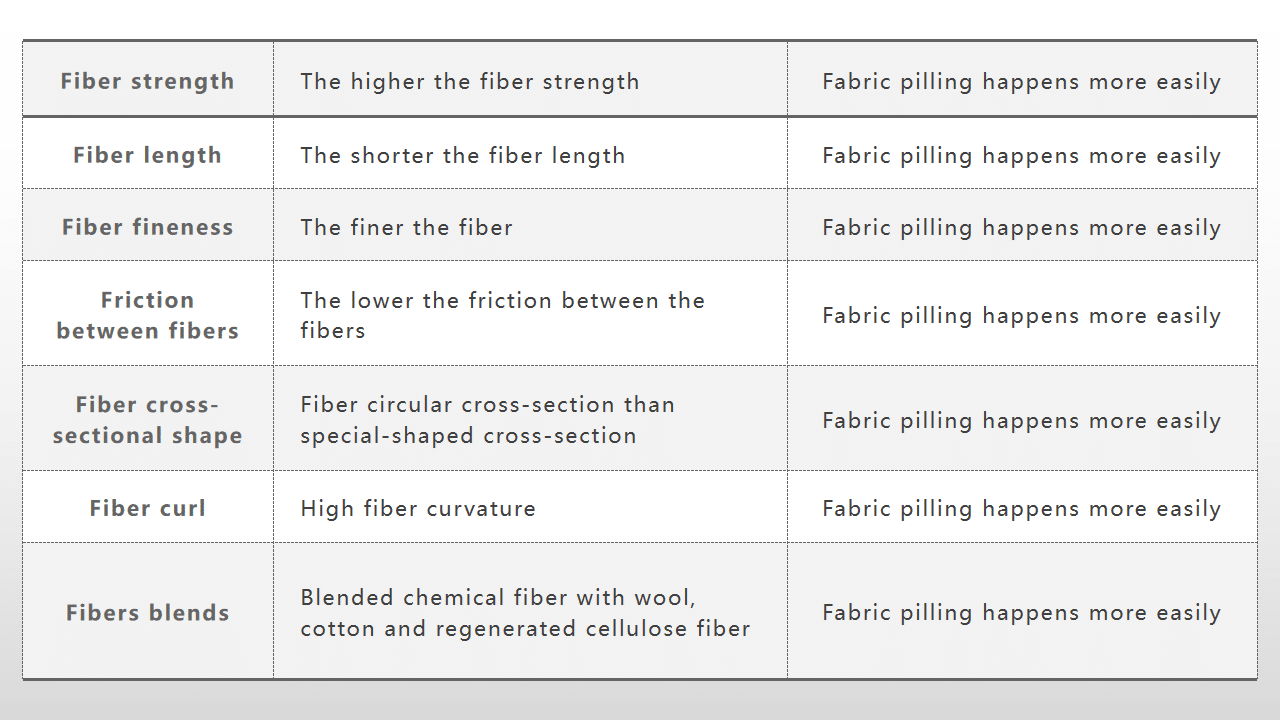

3.1.1. Fiber Properties Effects On Fabric Pilling

Here we list a comparasion table of the common effects by fiber properties on fabric pilling.

Fabric pilling factors – Fiber factors

- Fiber strength:

Fabrics with high power and inability to elongate, high resistance to repetitive bending, the ability of a fabric to resist abrasion will lead to friction. This will not make fabric worn out easy, but it makes susceptible to fabric pilling. If the strength of the fiber is strong, the forming of the hairball by friction is easy, and the formation of balls will occur and eventually fall off from the surface of the cloth. That’s why high fiber strength leads to quick fabric pilling.

- Fiber length:

The length of the fibers is also worthy of note. Short length fibers are prone to pill easier than longer fibers. This is because long fibers have greater resistance to friction and don’t pill easily, unlike short span fires. For cross-sectional areas, longer span fibers are less exposed due to their tight knitting than short fibers, increasing their resistivity to friction. Polyester filament yarns have greater resilience and are less susceptible to wear and tear and breakage when exposed to mechanical movements. They are less vulnerable to fabric pilling.

- Fiber fineness:

The finer the material, the higher the vulnerability to fabric pilling irrespective of the material. Due to the coarse nature of materials, they are likely to be bent and not get entangled, unlike a fine material.

- Friction between fibers:

Materials with a high level of resistance to friction are not easy to cause fabric pilling.

- Fabric pilling due to fiber blends:

Fabrics sometimes are made through blends of materials. A mixture of synthetic fibers and wool, cotton and cellulose fibers are easy to pill. This is possible due to the difference in the quality and resistance of these materials to fluffing.

- Fiber cross-sectional shape:

Fibers of the cross-section shape have high flexural density. They are not easy to bend and curl. The probability of close contact and tension is less, and so they are not easy to lift and not easy to pill.

- Fiber curl:

Curl fibers are good. The more they are curled, the less they can be stretched during the entanglement phase. The fibers here basically can’t get loose enough to slip during friction.

3.1.2. Yarns

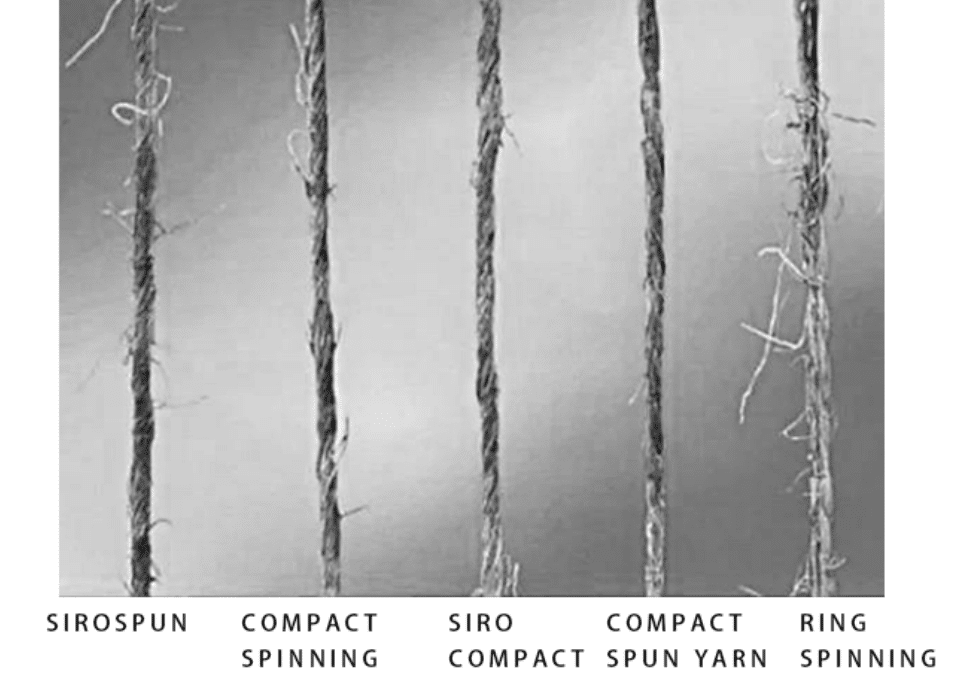

- Spinning method:

The spinning method is crucial to fabric pilling. One of the major reasons why fabrics pill is wear-resistance and hairiness of the yarn. The yarn twist, structure, and other factors are necessary concerns and should be looked out for. Combed fibers are not prone to fabric pilling. This is because the combed yarn is straight and short fibers are not used. The fibers used are generally long, and hairiness is low.

- Spinning process:

The fiber is exposed to frequent drawing and carding during the whole spinning process. If the process specifications are not set correctly, and the machinery is not in good condition, the fiber will be easily degraded and discarded during the process, resulting in an increase in the short-staple, which will increase the hairiness and decrease the anti-pilling feature of the fabric.

- Yarn twist:

A high twist decreases the hairiness of the thread and is less likely to trigger pilling, but increasing twist lowers the strength of the cloth and changes the feel and look of the cloth.

- Yarn structure:

Changing the thread structure will also somehow increase the thread’s wear resistance. In the modern ring spinning yarn technology, by adjusting the spinning mechanism and turning the yarn into a specific structure, such yarn hair less than the conventional yarn under the same method. This increases the wear resistance of the cloth and greatly increases the anti-pilling efficiency, thus makes the fabric pilling happen less.

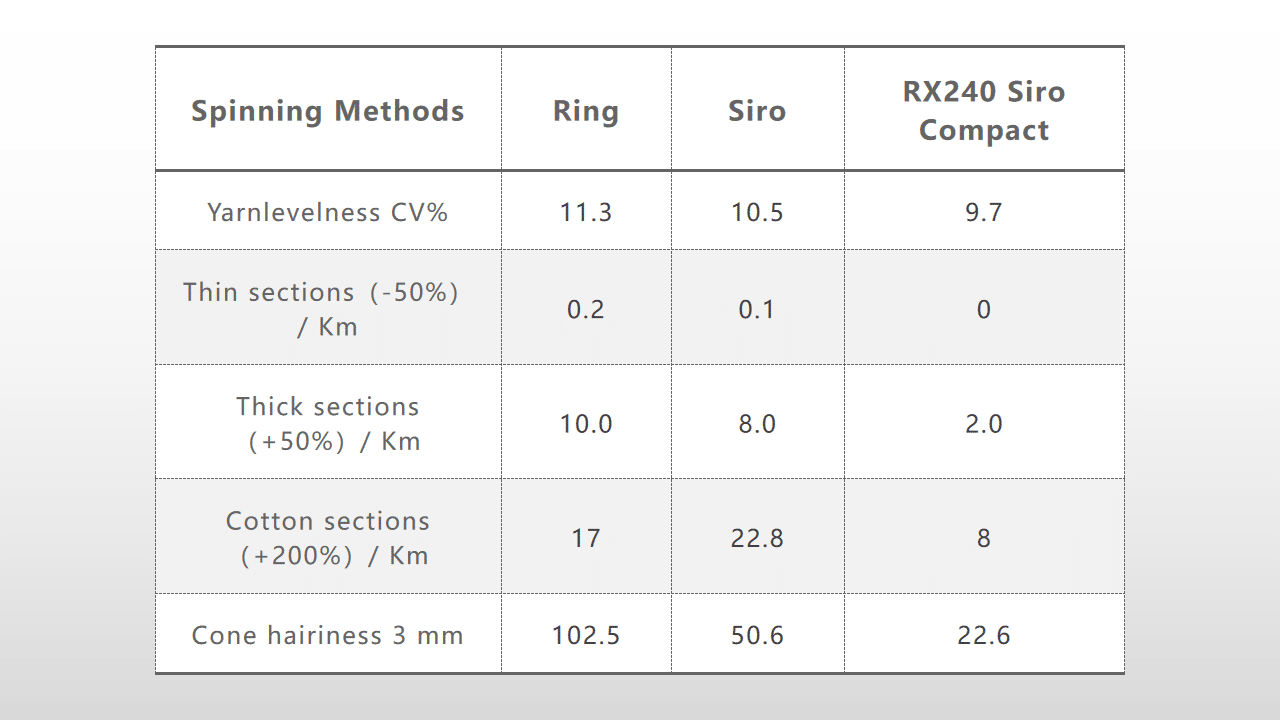

The quality comparison table of ring spinning, Siro spinning and Siro compact spinning of R19.7 tex models:

3.1.3. Fabric structure effecting fabric pilling

- Closeness:

The closer the structure of a fabric, the lesser it is to produce fluff. This is possible due to the frictional resistance between the fibers that are larger than loose fabric. To reduce the phenomenon of fabric pilling, one must create fabric such that they are knitted tightly, and this will reduce the exposure of the yarn to the surface area. For the loose fabric, the framework is comparatively loose, usually simpler than woven fabric pilling; even though high machine number fabric is usually finer, the fabric of low machine number than the fabric of high machine number pilling. The fabric with a loose structure is easier to pilling than the fabric with a compact structure.

- Surface flatness:

The flat surface fabric is not vulnerable to result in fabric pilling as much as the uneven surface fabric. Hence, the ordinary fabric with a flat surface is stronger and capable of withstanding friction than a rough surface. The more the uneven layer, the more the ability to pill increases. The structure of fabrics and their tendency to pill, the smoothness at the surface, and the intersections are all related and interwoven.

In a bid to compare;

- Woven and knitted fabrics pill easily.

- Weft knitted fabric pill quicker than warp knitted fabric.

- Coarse gauge materials are simpler to pill than materials with fine gauges.

- For ribbed fabrics, pilling is simpler than for simple fabrics.

- Fabrics with low gauge are less resistant to pilling than fabrics with a high gauge.

- Heavyweight fabrics don’t pill easily like lightweight fabrics.

- For the same type of fabric, the tighter the structure, the less likely it is to pilling.

3.1.4. Impact of the method of dyeing and finishing

The finishing process and fabric pilling share a link. The thread or fabric after dyeing and finishing affects the possibility of pilling. Anti-pilling and pilling properties of the fabric will create large changes related to the conditions of dye, auxiliaries, and the finishing. The method of dyeing influences the strength of the fiber and the tension between fibers, thus influencing the efficiency of pilling.

When fabrics are created, softening is done. The rationale behind softening is to improve the feel and elasticity of the fabric. One must make sure while softening is being done. The chemical used to achieve this isn’t overly used because this might cause the fabric to lose its resistivity to friction. In the course of wearing and cleaning, the fabric will quickly absorb particles, which will have an anti-pilling effect. The residual particles will reduce the strength of the fibers and make them stretch, which will generate the pilling. There should be fair optimization of the finishing process parameters, including temperature, the quantity of finishing agent, time of finishing.

3.2. Four major fabric pilling driving factors; Consumer view

3.2.1. Material pilling.

Some fabrics are naturally vulnerable to become fabric pilling, such as bamboo fiber, wool, polyester cotton, etc. They either have shorter fibers because they have more ends when spinning, or they don’t tie the fibers together as well. This leads the cloth to fall apart after scratching, an issue that can’t be avoided unless you lose the texture of the cloth.

3.2.2 Fiber Mix Spinning.

Each fabric component has its characteristics and advantages. Polyester-cotton fiber is shinier than cotton. It’s a hybrid cloth because it has a stronger sense of gloss, but since the two fibers are not the same weight, after rubbing, the synthetic fiber flows out of the cotton, making the cloth pill.

3.2.3 Low-threaded twist

Some of the fabrics are very rough, and some are very soft based on the twist of the thread. Spinning twisted yarns is like spinning a rope; lightly twisted yarns are naturally durable and solid, and easily twisted yarns are naturally fragile. Owing to the low knot, the hold strength of the fibers is low, and there would be friction and pilling

3.2.4 Washing without attention

When fabrics aren’t washed properly or washed carelessly, farbic pilling occurs. Cloth soaking, material mixing while washing, and color mixing are all the causes of fabric pilling. They should be avoided.

CHAPTER 4: POPULAR, EASY-TO-PILL FABRICS TO WATCH OUT FOR

A guide to picking out clothes that are less vulnerable to pilling

Research has shown that fabrics and material will always pill. This is because all material and things have an expiration time, especially as they are being used. One must pick out the material, textile, fabric according to its intended purpose and the requirement it needs to fulfill. Picking out fabric for fashion trends will require a different approach than picking out fabric for interior decoration purposes.

Picking out an anti-pilling fabric can be tedious, but following these steps can be helpful.

- Avoid fabrics that are fiber blends. These fabrics are prone to pilling easily. Fabrics that are woven or knitted with different threads, especially those that combine natural and synthetic fibers-are more likely to pill.

- Check the label before you purchase an item.

- Choose woven fabrics over knits. Despite the ability of woven fabrics to not pill quicker than fabrics that are knitted, the purpose of purchase is still very much important.

- Wool and its blends

Knitted sweaters, tweeds, wool sweaters, etc.

- Chemical staple fibers and blended fabrics

Polyester cotton, polyester viscose, acrylic cotton, etc.

- Lightweight knitted fabrics

Recycled cellulosic fabrics such as cotton drawstrings, modal, viscose, and Tencel.

- Denim embroidery

CHAPTER 5: SOLUTIONS TO FABRIC PILLING

The textile industry has always found solutions to fabric pilling. With the growth of technology, there are more mechanisms, methods, and processes to solve and prevent fabric pilling. Some of these techniques include singeing the loose fibers protruding on the surface of the fabric, the spinning of thread/yarn with a high number of twists per inch. In order to minimize their susceptibility to pills, certain materials are chemically prepared during the production phase.

Often polymeric coatings are added to attach fibers onto the surface of the cloth to avoid the development of initial fuzz. Polyester and cotton fibers are often engineered to have lower strength than usual, resulting in simple removal of pills from fabrics until they are formed. Cellulase enzymes are often used during wet processing on cotton fabrics, which extract loose fibers.

Textile officials claim that by treating fabrics with chemical soil release treatments that make the surface of the fabric more hydrophilic and by turning clothes inside out before washing them, customers can avoid or delay the pilling of their fabrics. Washing with enzyme-containing laundry detergent can get rid of pills on cotton clothes.

5.1 For Manufacturers

Research has shown us the solution for the textile industry premised on three major questions:

- How do you control the quality of the fabric pilling?

- How do garment manufacturers solve the problem of fabric pilling at the source through scientific production methods and processes?

- Is fabric pilling better-taken care of at the early stages?

The answers to these questions vary across the board, but the average solution is that some finishing techniques effectively solve fabric pilling. Solutions like shearing treatment, burning, heating, polyester shrinkage tend to reduce the advent of fibers from the surface and slows fabric pilling. Manufacturers should follow the under listed guide to improving their production process.

- Wool burning process:

The reason why burning is needed is to burn the lint off the cloth surface and, in the case of polyester fabrics, enhance the cloth finish. The burning off process would impact the human-made fiber fabric’s internal consistency and decoration design. Finding an established mill is possible. Do not use a heavy heat, so that the cloth does not feel rough.

- Resin finishing agent:

The lipid body penetrates the fibers in the process of using the resin, and the fibers bond with the velvet. Then by baking at high temperatures, an insoluble network structure is formed to achieve the anti-pilling, anti-pilling effect. Adding magnesium chloride catalyst should be sufficient volume, first dissolved diluted before adding, to avoid precipitation of the resin finishing agent, affecting the anti-pilling effect. Also, attention should be paid to the temperature, too low lipid solubility is not adequate, too high fabric strength has decreased.

- Special process yarns:

The process of spinning is very important. The spinning method is complicated, and at least producers can prefer strong fiber neatness, fewer impurities, and poor fiber holding power. Suppliers should also search for skilled anti-pilling yarn suppliers, such as Qingdao Wilin Textile or cotton Wan Song Yi. Try not to select a certain anti-pilling effect, but pick based on how hard the yarn feels.

- For Users

Users of fabrics need to also be careful in their usage and how they solve fabric pilling. In cases where pilling is a big concern for the user, it is advisable to go for known brands with better quality and are known not to pill. There are many ways to extract pilling from your cloth but using a battery-powered pill shaver or remover is the most efficient and cheapest way to eliminate pilling from fabrics and textiles. The system is cost-effective and very useful for eliminating the pilling of cloth and can be purchased from most sewing or garment shops. Another way to remove the pilling on fabrics and wears is to use a pumice stone pill remover or pill comb.

The device is cost effective and very good to remove fabric pilling and it can be bought at most sewing or textile stores. Another way to remove the pilling on fabrics and wears is the use of pumice stone pill remover or pill comb are also effective and they are manually operated.

CHAPTER 6: CONTEMPORARY METHODS OF DETECTING FABRIC PILLING AND HOW THEY WORK

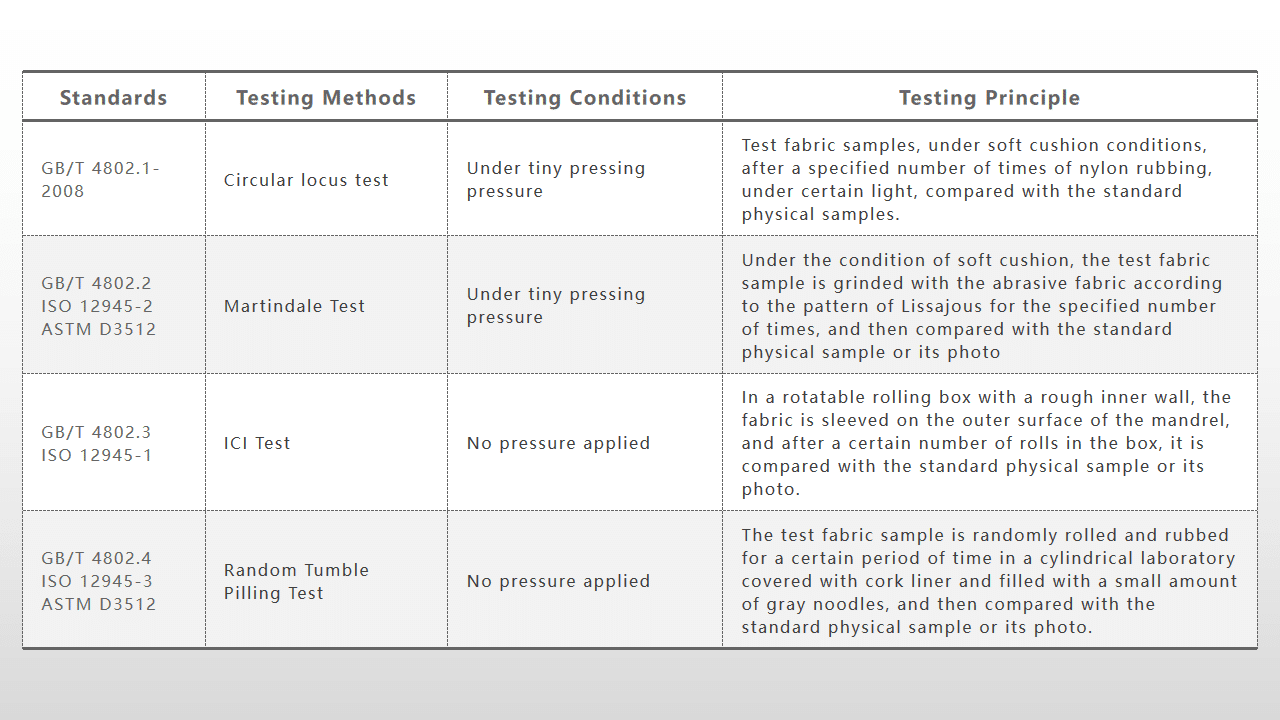

The most convenient way to test fabrics for fabric pilling is by continuous rubbing, which causes friction and heat, and leads to fabric pilling. The rate at which this happens leads to a result and a categorization of the fabric. The ranking is performed using the traditional form of sample contrast, meaning it is applied to a standard sample of a particular product. The circle track method, Martindale technique, fabric pilling box method, and random tumbling method are widely used research methods for fabric pilling resistance.

Various criteria use common testing methodology such as:

- Chinese standard GB/T4802.1-2008 “the determination of pilling performance of textile fabric pilling part 1: circular track method”.

- Chinese standard GB/T4802.2 “the determination of pilling performance of textile fabric pilling Martindale method”.

- Chinese standard GB/T4802.3 “the determination of pilling performance of textile fabric pilling box method”, “the determination of pilling box method”, “the determination of pilling performance of textile fabric”.

- Chinese standard GB/T4802.4 “Determination of linting and pilling properties of textile fabrics by random tumbling method”.

- International standard ISO12945-1 “Determination of pilling of textile fabrics by the pilling box method”.

- International standard ISO12945-2 “Determination of pilling of textile fabrics by the Martindale method”.

- International standard ISO12945-3 “Determination of pilling of textile fabrics by the random tumbling method”.

- American Society for Testing and Materials standard ASTMD3512 “textile fabric pilling performance of the determination of random tumbling method”.

- The American Society for Testing and Materials standard ASTMD4970 “textile fabric pilling performance of the determination of Martindale method”.

The above standards using different methods of fabric pilling testing principles and test conditions are demonstrated in Table 1:

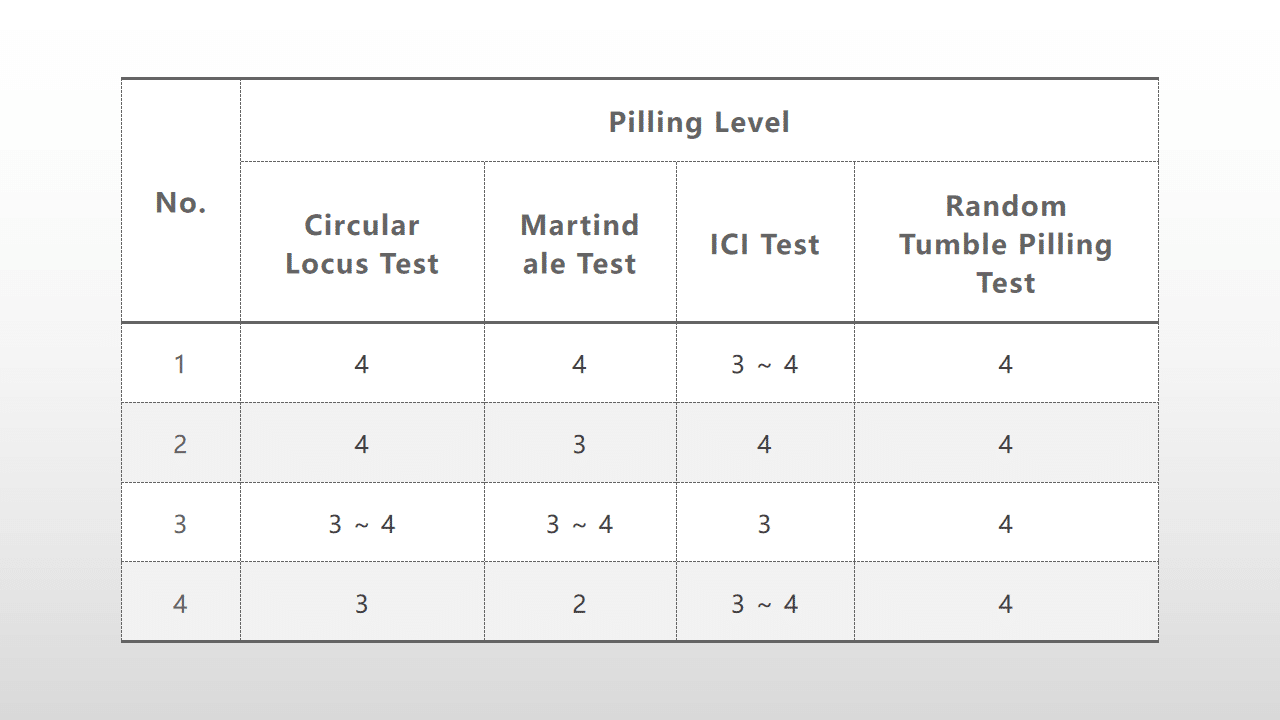

Due to the different test methods, conditions, and principles, the anti-pilling performance of the same piece of fabric varies greatly. The influence of different test methods on the anti-pilling grade of the fabric is demonstrated in Table 2:

Due to the different test methods, conditions, and principles, the anti-pilling performance of the same piece of fabric varies greatly. The influence of different test methods on the anti-pilling grade of the fabric is demonstrated in Table 2:

From Table 2, we can tell that due to multiple test methods, there are variations between the test outcomes.

For textile export companies in different countries that face different trade standards, in terms of anti-pilling testing, the choice of suitable research methods should be focused on the use of goods and consumer specifications. The specifications of clients for fabrics are getting higher, so many international research criteria should be studied by testers. Pay attention to the testing requirements expected in a trade deal by the consumer market and the exporting countries. Perform testing and grading in full compliance with their specifications to reduce the effect on production and revenue due to a lack of understanding of regulations, resulting in losses for both consumers and the company.

CHAPTER 7: CONCLUSION

Manufacturers and consumers alike aren’t very happy with the phenomenon of cloth fabric pilling. Fabric Pilling is a clothing flaw that affects everyone. Technology has, among others, produced such techniques such as singeing and spinning to avoid pilling of fabrics. The concept of pilling resistance tests has already been embraced by cloth and clothing firms;

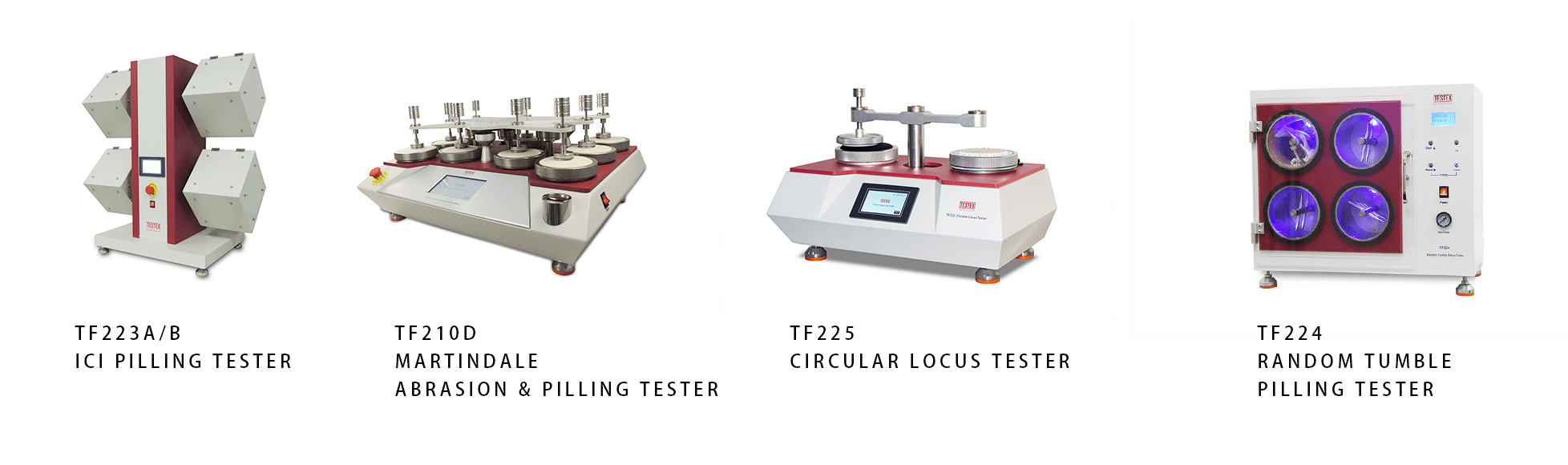

As a proffesional textile testing instrument brand, We have included the garment testing equipment to help you overcome the issue of cloth fabric pilling.

For questions or inquiries about fabric pilling tester, feel free to contact us.

This Post Has 33 Comments

Leave a Reply

You must be logged in to post a comment.

I am so grateful for your post.Much thanks again. Much obliged.

Wonderful story, reckoned we could combine a few unrelated information, nonetheless truly really worth taking a look, whoa did 1 find out about Mid East has got far more problerms also.

I was just looking for this info for some time. After 6 hours of continuous Googleing, finally I got it in your site. I wonder what’s the lack of Google strategy that do not rank this kind of informative websites in top of the list. Normally the top sites are full of garbage.

The data mentioned inside the write-up are some of the very best out there

Every after inside a when we decide on blogs that we read. Listed below would be the most up-to-date internet sites that we select

Nice read, I just passed this onto a colleague who was doing some research on that. And he actually bought me lunch since I found it for him smile Therefore let me rephrase that: Thanks for lunch!

We are a group of volunteers and starting a new scheme in our community. Your site offered us with valuable info to work on. You’ve done a formidable job and our whole community will be grateful to you.

although websites we backlink to beneath are considerably not related to ours, we feel they may be essentially really worth a go by means of, so have a look

Thanks for posting this awesome article. I’m a long time reader but I’ve never been compelled to leave a comment. I subscribed to your blog and shared this on my Facebook. Thanks again for a great article!

Great – I should definitely pronounce, impressed with your site. I had no trouble navigating through all tabs and related information ended up being truly simple to do to access. I recently found what I hoped for before you know it in the least. Quite unusual. Is likely to appreciate it for those who add forums or anything, website theme . a tones way for your customer to communicate. Excellent task.

I really like your writing style, wonderful information, thanks for posting : D.

I haven’t checked in here for a while since I thought it was getting boring, but the last several posts are great quality so I guess I’ll add you back to my daily bloglist. You deserve it my friend 🙂

Absolutely composed content material, Really enjoyed studying.

Its like you read my mind! You seem to know a lot about this, like you wrote the book in it or something. I think that you can do with a few pics to drive the message home a little bit, but other than that, this is magnificent blog. A great read. I will definitely be back.

just beneath, are many completely not associated websites to ours, on the other hand, they are certainly worth going over

This is really interesting, You are a very skilled blogger. I have joined your rss feed and look forward to seeking more of your great post. Also, I have shared your website in my social networks!

I simply want to mention I am newbie to blogging and site-building and really loved this web site. Likely I’m likely to bookmark your website . You certainly come with terrific well written articles. Bless you for sharing with us your website page.

one of our visitors a short while ago suggested the following website

I just want to tell you that I’m all new to blogs and definitely savored your blog site. More than likely I’m want to bookmark your site . You actually have superb well written articles. Cheers for sharing with us your web-site.

Here is an excellent Weblog You might Find Fascinating that we Encourage You

check beneath, are some absolutely unrelated web-sites to ours, having said that, they’re most trustworthy sources that we use

The information talked about within the report are a few of the most effective obtainable

we came across a cool site that you just might take pleasure in. Take a search should you want

Here are several of the web pages we advocate for our visitors

here are some links to web pages that we link to mainly because we consider they are really worth visiting

just beneath, are a lot of completely not related web sites to ours, however, they may be surely worth going over

Wonderful story, reckoned we could combine some unrelated information, nonetheless definitely really worth taking a search, whoa did 1 master about Mid East has got additional problerms also.

please take a look at the sites we comply with, which includes this one particular, as it represents our picks from the web

Every the moment in a whilst we select blogs that we read. Listed below are the most up-to-date internet sites that we decide on

One of our guests recently advised the following website.

One of our guests recently recommended the following website.

Sites of interest we’ve a link to.

Id have to check with you here. Which is not something I usually do! I enjoy reading a post that will make people think. Also, thanks for allowing me to comment!