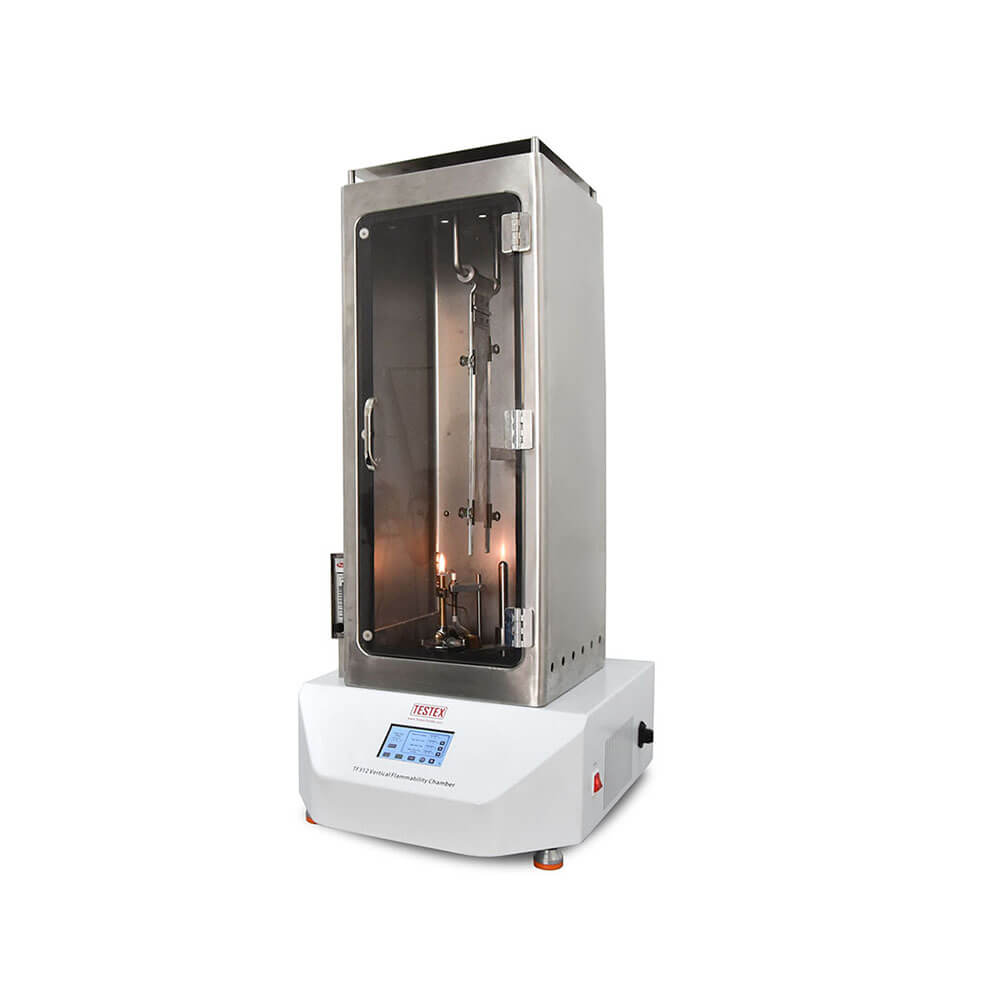

Vertical Flammability Chamber TF312

Vertical Flammability Chamber TF312 is designed to measure the flame resistance of textiles(vertical test) or products like children’s sleepwear, evening dress for children and adults, special industrial wearings, curtains, as well as resilient filling materials used in upholstered furniture, and so on. Vertical flame test Chamber complies with ASTM D6413, CALIF TB117, 16CFR Parts1615/1616, etc. Each flammability test method refers to a specific testing requirement. TESTEX is one of the advanced manufacturers of Vertical Flammability Chamber with a history of over ten years. Feel free to contact us if needed.

Description

Parameter

| Ignition time: 12+/-0.2 s or 3+/-0.2 s |

| Distance from the igniter to specimen: 19 or 17 mm |

| Burner size: 10mm / 11mm x barrel length 76+/-6mm |

| Dimension of holder : 442 x 76 / 442 x 89mm outside, 356×51 mm interior |

| Time Display and accuracy: 0-999.9s, 0.1s |

| Accessories: Weights, Specimen holder, Flame measuring tape, Steel ruler, Sampling plate (optional: Weights, Specimen holder) |

Specification

| Model | TF312 |

| Standards | ASTM D6413, (optional: 16CFR Parts 1615/1616, CALIF TB 117 Method A, CPAI 84, GB/T 5455) |

| Power | 220/110 V, 50/60 Hz |

| Weight | 45 Kg |

| Dimensions | 550 mm * 520 mm * 1010 mm |

TESTEX – a professional textile testing instrument supplier – Vertical Flammability Chamber TF312 is on sale, contact us to get a detailed quoted price.

What is the Vertical Flammability Chamber?

Vertical Flammability Chamber TF312 is designed to measure the flame resistance of textiles(vertical test) or products like children’s sleepwear, evening dress for children and adults, special industrial wearings, curtains, and so on.

The burner ignites the specimen automatically, and the ignition time is programmable. Therefore, it is very convenient to carry out the test. And then there will be after-flame time and afterglow time on the display. It is convenient to operate the machine due to the user-friendly design of the control panel and the touch screen. Finally, the screen will show the test results when the vertical flammability test is over. Besides, it is comprised of a draft-free stainless steel flammability chamber with an observation window for easy test viewing. Moreover, specimen holders, burners, and associated hardware are dependent on the test standard and must be specified.

Vertical flame resistance test standards of textiles

There are many test methods for flame resistance of textiles, and different kinds of fabrics have different test methods. The applicable standard for vertical flame test of TF312 is briefly introduced below.

- ASTM D6413: Standard test method for flame resistance of textile (Vertical test)

- 16 CFR Parts 1615/1616: Standards for the flammability of children’s sleepwear

- CALIF TB 117: Requirements, Test Procedure and Apparatus for Testing the Flame Retardance of Resilient Filling Materials Used in Upholstered Furniture

- CPAI 84: A sepcification for flame resistance materials used in camping tentage

- GB/T 5455: Textiles – Burning behaviour – Determination of damaged length, afterglow time and afterflame time of vertically oriented specimens

How to test the flame resistance of textiles?

Place a certain size sample on the specified sample holder for drying and cooling, and then place the sample in the vertical flammability chamber. Use the standard flame to ignite the lower part of the sample, measure the minimum ignition time, afterflame time, afterglow time, damaged length, etc. of the sample, and evaluate the flame resistance of the sample.

The test report

- Conditioning conditions of the specimen

- Description of the sample and test date, tester

- The selected gas, atmospheric conditions, or any deviations in the test

- Characteristics of specimens after burning, such as charring, melting, shrinkage, curling, etc.

- The measured value and the average value of after-flame time, afterglow time, as well as the damaged length of the specimen

7 reviews for Vertical Flammability Chamber TF312

You must be logged in to post a review.

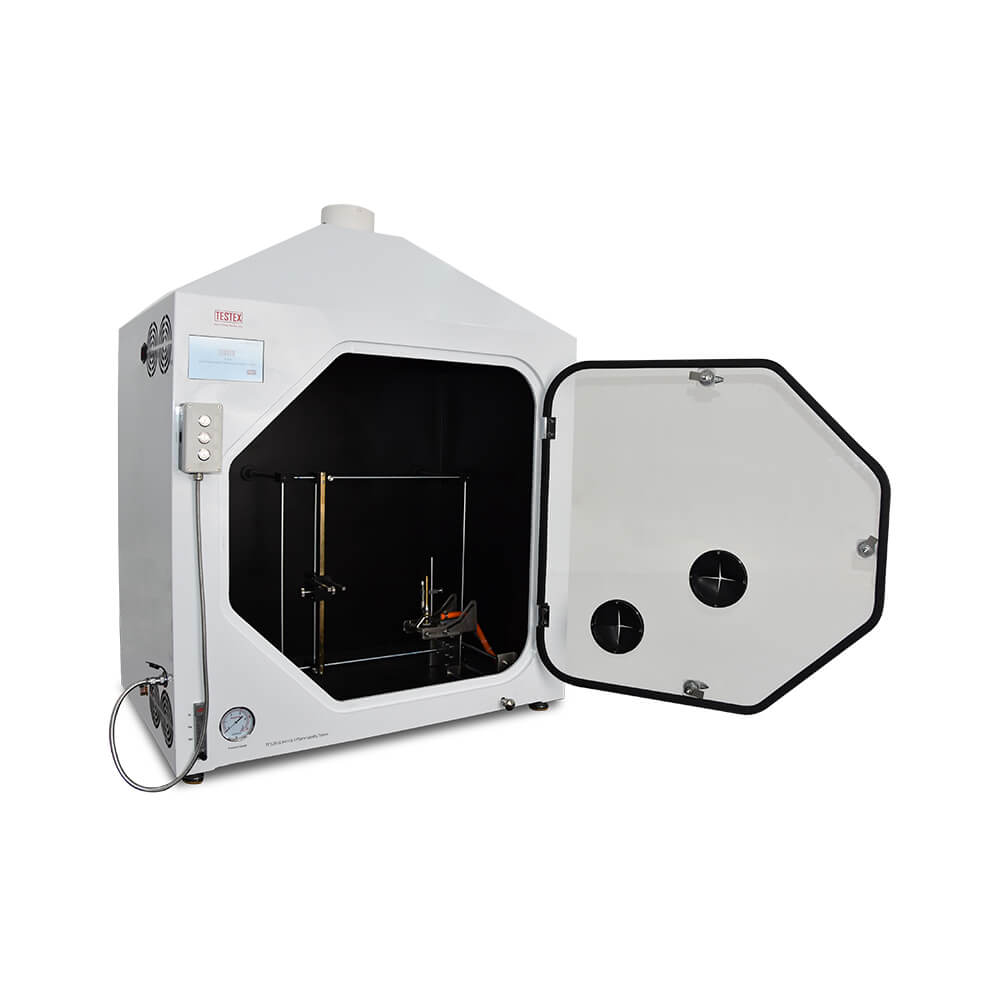

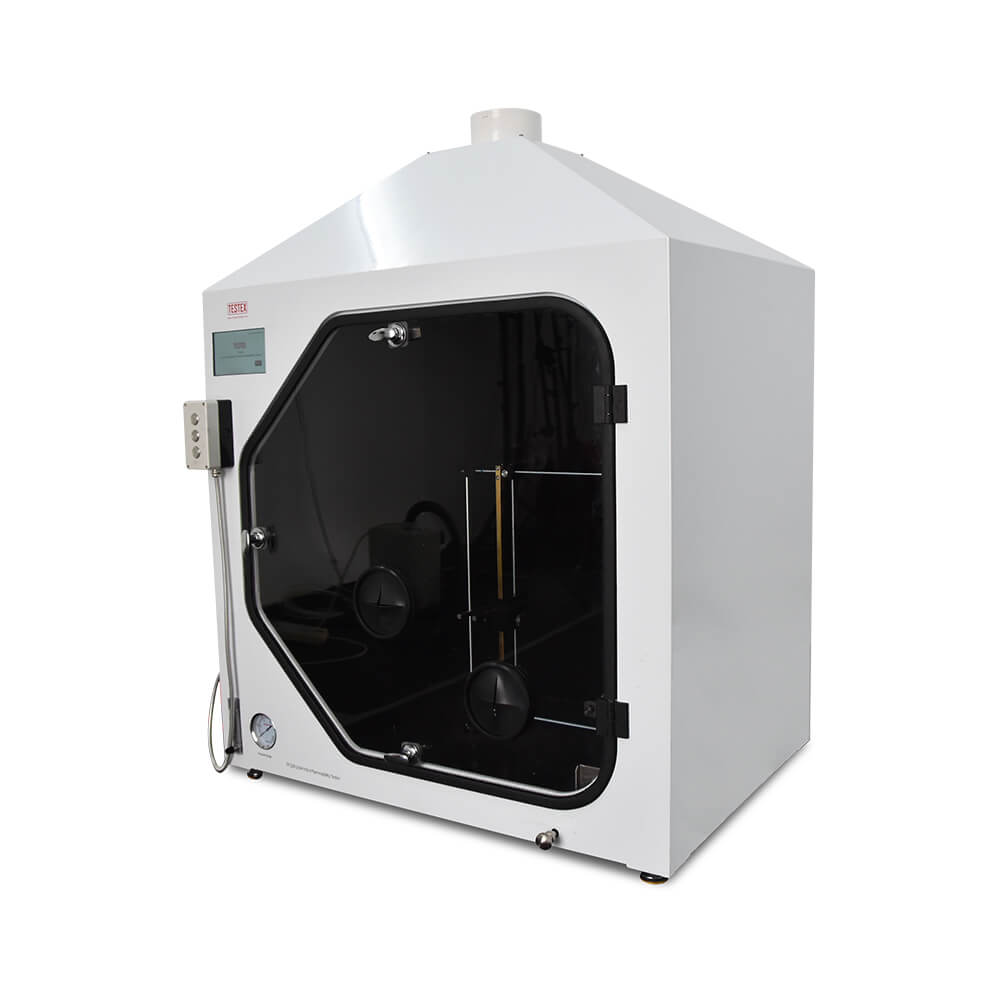

What is the Vertical Flammability Chamber?

The vertical flammability tester is used to test the combustion performance of children's pajamas or decorative fabrics. Flame spread speed can be tested accurately by the combined use of a sealed stainless steel combustor, an observation window, and a standard burner. Equipped with different sample clips and accessory test packages, the vertical flammability tester can meet different test standards. It is easy to control the testing process through an automatic gas control system. Here take the ASTM D6413 standard as an example to introduce the vertical flammability test of fabrics.

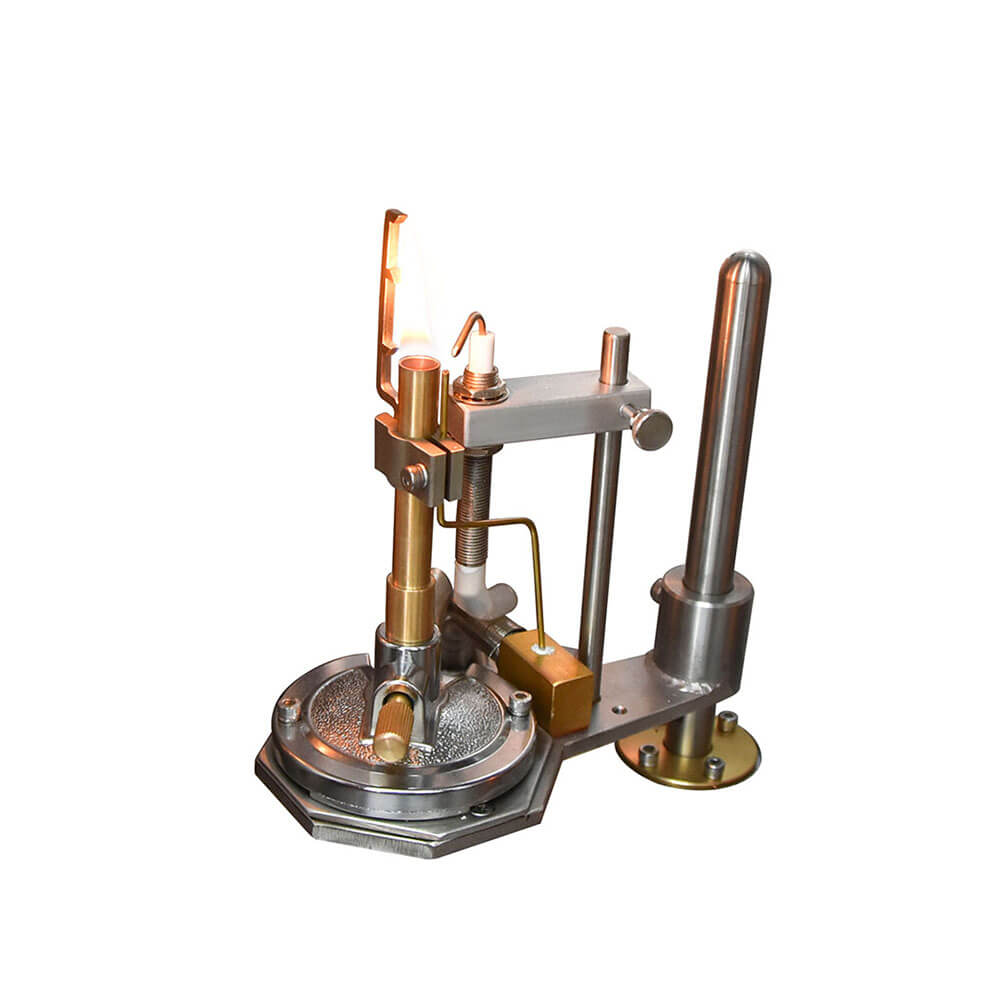

Regulating Instrument

Adjust the gas pressure to 17.2±1.7KPa and ignite the flame and the flame height to 3mm, and ensure the shape of the flame will not change within 12s. Next, close the vent and open the solenoid valve to ensure that the flame height reaches 38mm. Adjust the burner position to ensure the lower edge of the sample clip is in the middle of 19mm at the top of the burner. Meanwhile, the timer should be adjusted to ensure that the ignite time of the sample is 12±0.2s.

Sample Preparation

Cut 5 samples along the longitudinal and transverse directions with an area of 76mm * 300mm, and the sample should be kept to be flat. Then adjust the humidity of the samples as required and store them in the dryer.

Test Program

1 Remove the sample from the dryer, install the sample and set it on fire for 4 minutes.

2 Fix the sample with the sample clip, then put it into the test box, and adjust the burner to ensure the center point of the bottom edge of the sample is located at the position of 19mm above the burner.

3 Open the igniter and ignite the sample for 12±0.2s. Observe the melting and dropping of the sample during combustion, and record the observation results.

4 After removing the fire source, record the time of continuous combustion and the flameless combustion time of the material. Don't extinguish the fire because it affects the carbonation length.

5 Remove the sample clip from the test box and open the ventilation cabinet to remove the smoke from the test box.

6 Measure the carbonation length along the intact edge of the sample.

What should be Paid Attention to in the Vertical Burning Testing?

1 Whether the sample and the sample rack can be installed accurately has a great influence on the vertical burning test.

2 When cutting the sample, you should ensure it is flat and wrinkle-free. The upper and lower ends of the sample should be trimmed flush and the size should be as accurate as possible.

3 When placing the specimen on the specimen holder, you should pay attention to the specimen so that the lower end of the specimen is flush with the lower end of the specimen holder to ensure the measured length is accurate during the vertical burning test.

4 Suspension of the sample holder should be hung vertically above the igniter, not tilted. The center of the sample should be kept in the flame.

Terminology

after flame time

The length of time for which a material continues to flame after the ignition source has been removed.

afterglow time

The time afterglow continues after the removal of the ignition source and cessation of flaming.

damaged length

Under the specified test conditions, it refers to the maximum length of the damaged part of the material which is placed in the specified direction.

flame application time

The time interval for which the ignition flame is applied to a material.

[contact-form-7 id="16355" title="Inquiry"]

pitt –

Very good vertical fire hazard testing machine, good.

Jill Raleign –

The machine is easy to use and it has beautiful appearance. Thanks for your recommendation.

Gabrielle Milne –

Thanks manufacturer’s recommendation. A great flammability tester.

Norma Bruno –

Bookmarked this net! Excellent manufacturing.

Will Senior –

Excellent vertical flammability chamber! Recommend!!!

Hugo Hansom –

Got the device.everything works. the accuracy of the device is not checked. was packed well, came quickly. I recommend the seller and product.

Emma –

Very quickly delivered. everything fits the description. thank you for your cooperation!