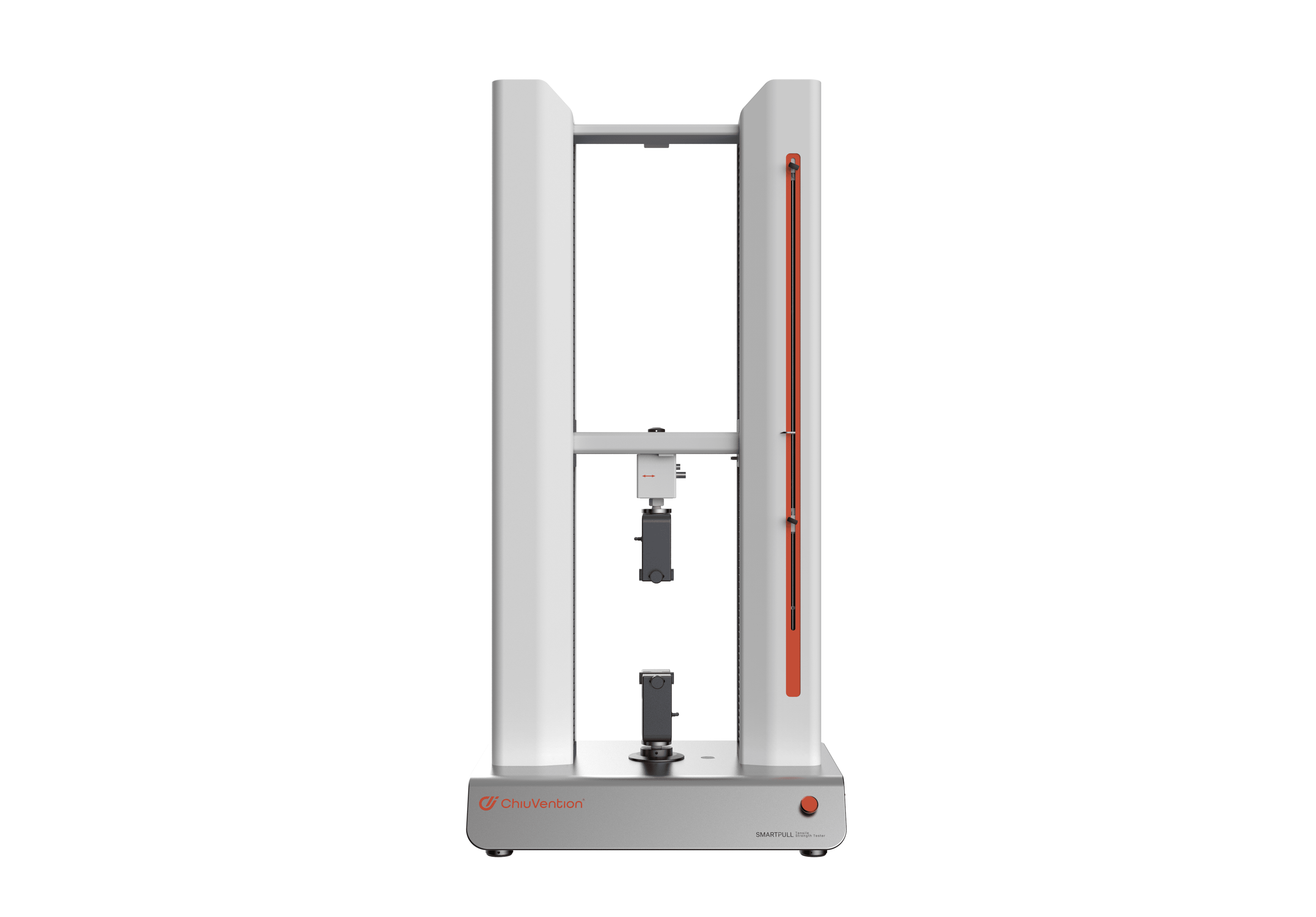

SmartPull Tensile Tester (Dual Column Type) | A new instrument developed by the sister company ChiuVention.

Fabric tensile strength tester, or fabric tensile strength machine, also named tensile strength testing machine is designed to test a wide range of materials, including fabric, leather, plastic, paper, etc, in tension, compression, flexure, bursting, shear, tear, elongation, constant load, elastic, thread slip, peeling and other mechanical properties. Fabric Tensile Strength Tester complies with ISO 13934.1/2, ISO 13935.1/2, ISO 9073.3/4, etc. And our fabric measuring machine for sale.

Description

SmartPull Tensile Tester is AC servo-driven and equipped with ball screws to provide stable pulling force and achieve higher testing accuracy. The software of the tester is compatible and powerful by outputting comprehensive test indexes, such as displacement, maximum force, elongation, stress, etc.; and there are various safety designs to protect the instrument and guarantee the operator’s safety. It is a tensile machine specially designed for textiles, leather, footwear, etc. It can do tension, compression, bending, tearing, shearing, peeling, and top-breaking tests. It applies to many international standards, such as 9073-3, ISO13934-1/2, ASTM D5034, ASTM D5035, ISO 3377-2, ISO 13937-3, FZ/T 01030, GB/T 19976, and so on.

TESTEX also provides another brand and type of tensile testers.

The Features of SmartPull Tensile Strength Tester

Higher testing accuracy

AC servo drive and ball screw achieve stable and constant pulling force, with force accuracy within 1%, this universal tensile testing machine ensures the reliability and repeatability of test results.

Powerful software

The test software can be applied to different languages and can present the displacement, maximum force, elongation, stress, maximum stress, bending stress, speed, and other test results. That is, by using this pull tester you can get more comprehensive textile property evaluation.

Safety guarantee for the whole testing process

This tensile tester is equipped with an intelligent and active displacement and torque alarm system, an overload and emergency stop device, and an up-down travel limiting device, the SmartPull tensile testing machine always keeps the testing process safe and stable.

It can be customized to meet diverse needs.

S-type load cell for pulling force of 5KN-10KN can be customized to realize more testing functions and the testing software also can be customized to realize automatic repeated testing.

Lightweight design

The SmartPull Tensile Strength Tester is 100 kg lighter than the initial generation, making it easier to handle and operate.

What are the differences between a single-column tensile machine and a double-column tensile machine?

1. Difference One: Appearance Structure

Obviously, one is single-column, the other is double-column (also known as the door type), double-column weight is heavier.

2. Difference two: Test Force Range

The single-column tensile machine uses a single screw, the double-column tensile machine has double screws, and the double-column tensile machine has a longer beam than the single-column tensile machine, so the test force is much larger. Therefore, the usually double-column tensile testing machine is more than 5KN for the material test (mainly in the 1 ton or more), single-column tensile tester for doing some small test force test, generally below 5KN, that is, below 0.5 tons.

3. Difference three: the specimen requirements

The activity space of the single-column tensile testing machine is relatively small, the bearing test force range is also small, and the size of the specimen requirements is relatively harsh, while the double-column tensile tester has bigger space, so the specimen requirements can be a wider range.

4. Difference four: whether the need to fix the machine

Because of the bigger space and test force of the double-column pull tester machine, the working platform is very large, in order to ensure accurate test data, generally need to build the foundation for fixing, while the single-column pull tester machine with lightweight and structure, generally do not need to be specially fixed.

5. Difference five: product cost

Due to the higher cost of the double-column tensile strength testing machine, so the price is much higher than the single-column tensile testing machine. But they each have their own advantages.

In general, single-column tensile strength machines and double-column tensile strength machines are different in the maximum load, effective test width, effective stretching space, test speed, speed accuracy, etc. But the standard and configuration are similar. Buyers need to consider that, due to the different materials, the test tension will be different, such as textile enterprises, generally choose a single-column tension machine, rubber enterprises can choose a single-column or double-column tension machine, and some metal enterprises, their demand for force values will be larger so that only double-column tension machine can meet the requirements. For details, you can consult TESTEX professional consultants.

Fixture and Testing Standards of Fabric Tensile Strength Tester

Software configuration (standard)

version A of the test system, with a single-step test

Software configuration (optional)

Version C of the test system can achieve a multi-step test

Fixture and standards

Version A :

ISO 9073-3, ISO 13934-1, ISO 13934-2, ASTM D5034,

ASTM D5035, GB/T 3923.1, GB/T 3923.2

GB/T13773.1,GB/T13773.2,GB/T 24218.3,

ISO 13937-2(sample with 50mm wide), ISO13937-3,

GB/T 3917.2(sample with 50mm wide), GB/T 3917.5

(The standards above are matched with clamps by 25×25 mm, 25×50 mm, 25×75 mm)

Optional fixture and standards

Version A :

ISO 9073-4, GB/T 3917.3 (clamps by 25×100 mm)

ASTM D5587 (clamps by 50×75 mm)

ISO 13937-4, ISO 4674-1, GB/T 3917.4 (clamps by 25×200 mm) Leather tearing fixture: ISO 3377-2

Top breaking fixture: ASTM D6797 FZ/T 01030 GB/T 19976

Yarn fixture: ISO 2062

Version C: ISO 13936-2, ASTM D4964 (U type fixture)

VersionC+: ASTM D434 ASTM D1683 ISO 13936-1

(The standards above need to be programmed according to the test requirements provided by customers.)

ISO 20932-1( with linear clamps, or choose other fixtures and replace the clamps)

Accessory

Standard accessories: pins, operation manuals, power cords, communication cords, control panels, fuses

Optional accessories: sampling plate

The Specifications of SmartPull Tensile Testing Machine

Testing capacity: 1000 kg

Test level: class1

Max Travel: 900mm (without fixture)

Travel accuracy: ≤1%

Travel speed: 1mm/min ~500mm/min

Speed accuracy: ≤1%

Test force range: 0.5% ~ 100%FS

Test force value accuracy: ±1%

Range of constant rate control: 0.5%~100%FS

Weight

| 160kg |

Power

| 220/110V | 50/60 Hz |

Dimensions

| Length: 830 mm | Width: 600 mm | Height: 1730 mm |

TESTEX Offer You One-stop Fabric Tensile Strength Tester Solutions

As a tensile testing machine manufacturer, from TESTEX, you can have a wide option of tensile test machines such as fabric tensile strength tester, but what makes us different is we put our effort most on light testing solutions.

TESTEX, a tensile testing machine manufacturer, provides you a one-stop solution for fabric tensile strength testers’ accessories, featuring a rich variety of grips and fixtures for different tensile testing purposes.

Before you choose which fabric strength testing machine is best suited for your requirements, TESTEX can understand your needs based on our rich experience in the testing industry. Just contact and tell us what kind of tensile testing problems you meet and hope to get a solution for your application, we will guide you through to the final step: choose the best testing system for you.

You must be logged in to post a review.

The significance of fabric tensile strength tester

The fabric is often subjected to tensile forces in various directions during wear, which is the main force that causes fabric damage. The ability of the fabric to resist tensile fracture is usually expressed by the index of resistance to single tensile fracture and the index of resistance to multiple tensile fatigue fracture. The tensile fatigue strength of fabric can indirectly reflect the wearability of fabric and occupy an important role in the internal quality evaluation of all kinds of fabrics, therefore, choosing a reliable fabric tensile strength tester will bring you more professional help.

The advantage of fabric tensile strength tester

- Touch screen control, built-in printer, support online communication, easy operation and high test efficiency.

- Single column bracket structure, multi-functional pneumatic gripper, easy to replace.

- High-precision sensor, can do tensile and top break test without replacing the sensor, more practical.

- According to customer needs can provide a variety of standard test functions, can also be customized according to customer requirements.

- The instrument uses a variety of protection measures: fixture anti-collision protection device; sensor overload protection; sample load software protection; over-current, overvoltage protection, etc.

- The instrument can be used with the professional strong machine detection software online, the software has the control instrument; test curve drawing; test data analysis, preservation, management; test report formation, printing and other functions, make the test results more intuitive.

The procedure for fabric tensile test

Adjust the position of the moving beam, the installation fixture, and then adjust the lower limit block position, to ensure that the instrument down to the lower limit to stop, the gap of the breach is not less than 5mm.

Tap the sensor with your finger to see if there is no change, if there is no change, check whether the sensor cable is plugged in, and then calibrate the sensor.

Set specific parameters on the setting interface of the touch screen, start testing, record the corresponding test results.

Daily Maintenance

- Clean after each test and keep the equipment clean.

- The fixture should be coated with anti-rust oil storage after use.

- The power should be turned off before replacing the sensor or plug the cable, if the sensor access side floating, it is easy to cause static damage.

- The instrument should be regularly calibrated to the load cell to ensure that the accuracy of the measured value of the instrument.

- Add lubricant to the moving parts regularly.

As a professional fabric tensile strength tester manufacturer and supplier, we have the right fabric tensile strength tester price. Fabric tensile strength tester is on sale, we will send you a detailed manual and provide you with more professional help if you buy our digital tensile tester.

[contact-form-7 id="16355" title="Inquiry"]

A: Yes. Yarn testing and zipper testing are done according to ASTM D434 and ASTM D 2061 standards respectively, and corresponding clamps will be equipped.

Reviews

There are no reviews yet.