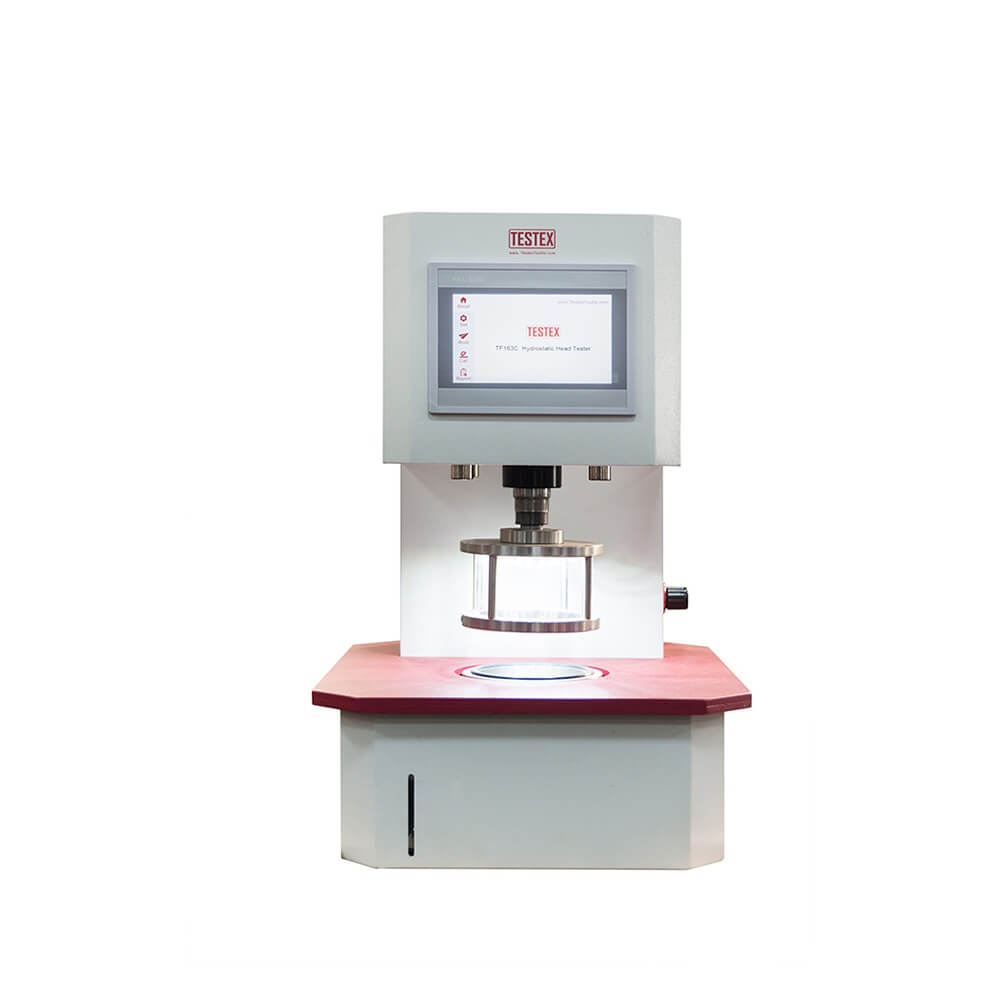

Sweating Guarded Hotplate TF129

Sweating Guarded Hotplate TF129 is used to test the thermal resistance and water-vapor resistance of textiles. The thermal resistance of textiles is a garment comfort indicator, representing the warmth of textiles, which can also be interpreted as the resistance to heat, the greater the thermal resistance, the better the warmth. Textile water-vapor resistance is also a clothing comfort index, representing the resistance of textiles to moisture, the greater the water-vapor resistance, the worse the clothing-wearing comfort will be.

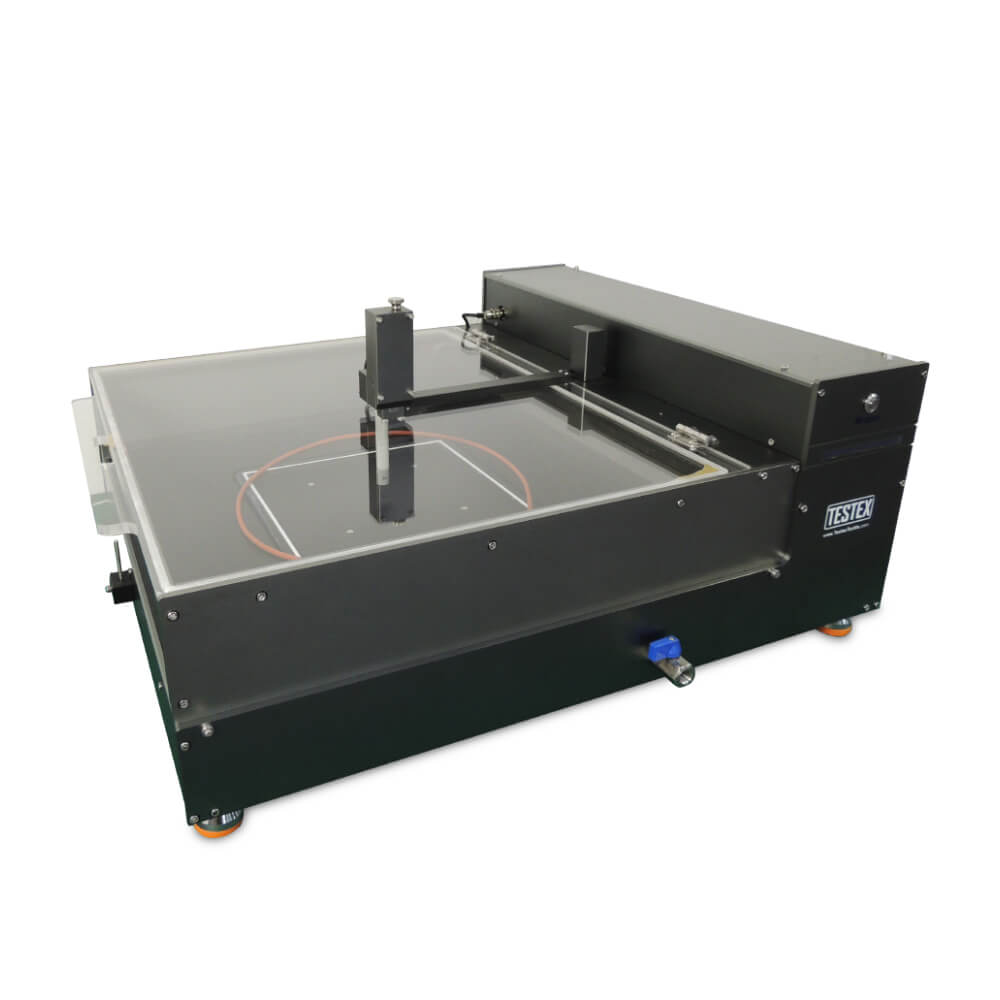

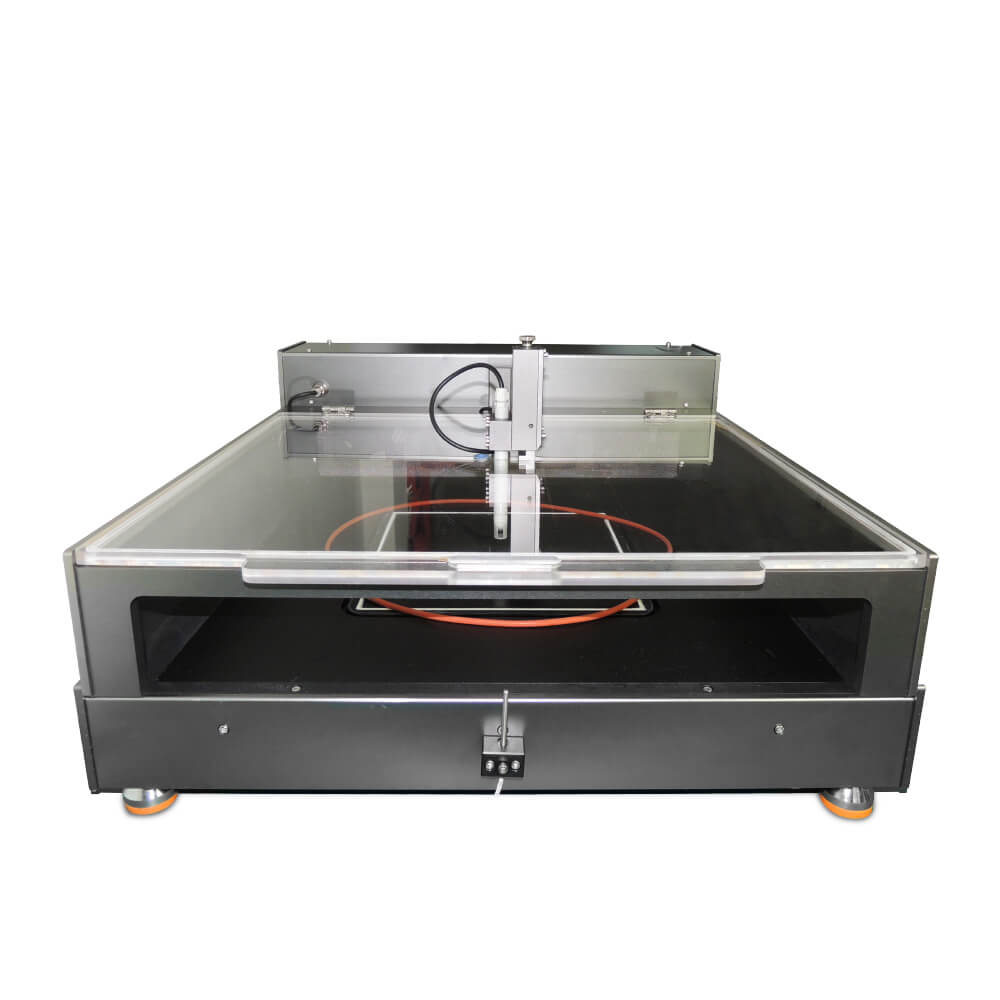

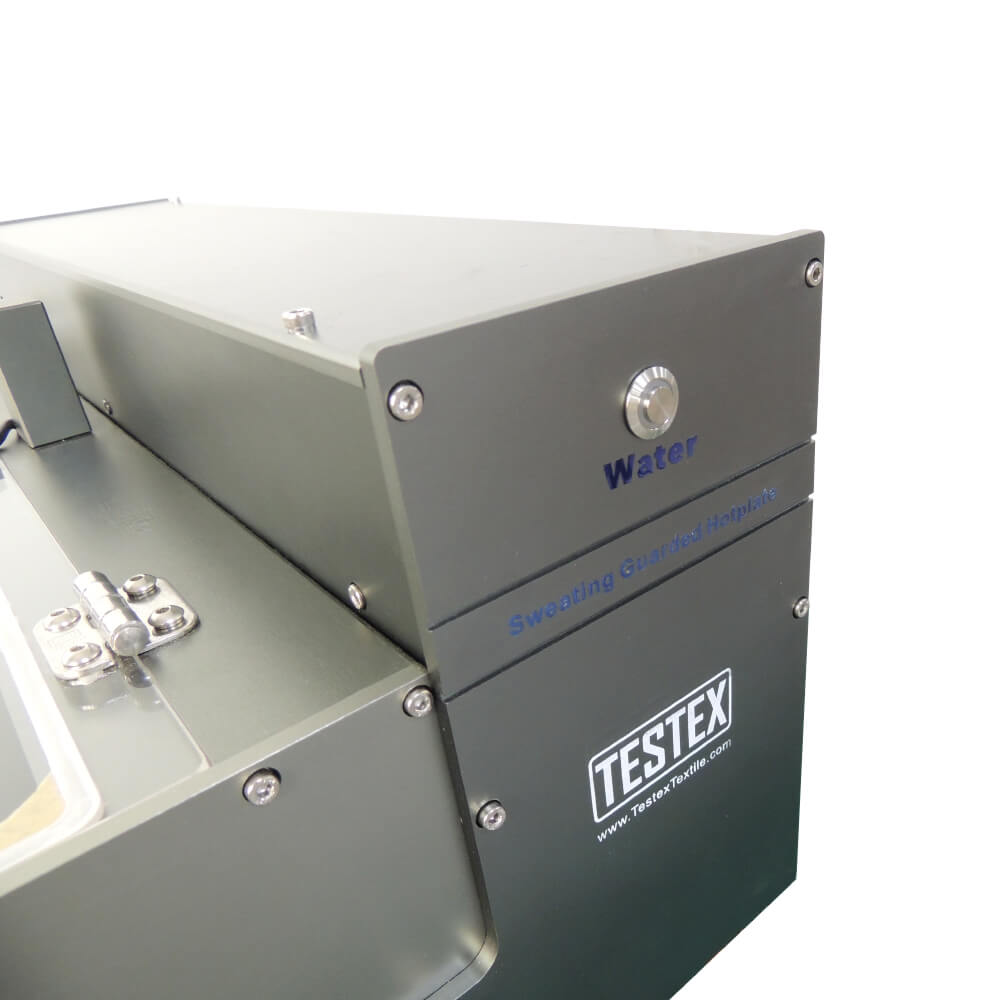

Sweating Guarded Hotplate TF129 consists of a human skin simulation test board, automatic water supply system, wind speed stabilization system, test host, etc. At the same time, an environmental chamber needs to be configured, because the test board is placed in the environmental chamber in order to meet the requirement for the test.

TESTEX Sweating Guarded Hotplate TF129 is currently sold to 42 countries and complies with ISO 11092, ASTM F1868, GB/T 11048, etc. We also offer a range of textile testing instruments, please contact us today for a special offer.

Description

Parameter

| Thermal resistance range: 0.001-2 .0 m²·K/W, Resolution: 0.0001 m²·K/W |

| Evaporative Resistance range: 1-1000 m²·Pa/W, Resolution: 0.001m²·Pa/W |

| Repeatability: ≤ ±2% |

| Test plate temperature range: 30℃ ~ 40℃, adjustable, accuracy: ±0.2℃ |

| Air velocity: 0 ~ 1 m/s, adjustable, accuracy: ±1% |

| Sample thickness: 0~50 mm |

| Test plate area: 254 mm x 254 mm |

Specification

| Model | TF129 |

| Standards | ISO 11092, ASTM F1868, GB/T 11048 |

| Power | 110/220 V, 50 Hz |

| Weight | 62 Kg |

| Dimensions | 770 mm x 670 mm x 430 mm |

TESTEX – a professional textile testing instrument supplier – Sweating Guarded Hotplate TF129 is on sale, contact us to get a detailed price quote.

Features of Sweating Guarded Hotplate TF129

More advanced testing method

A method of hot plate method, processed with special materials, replacing the previous porous plate form, high simulation of skin sweating effect. And name sweating guarded hot plate test method too.

You can use our sweating-guarded hot plate instrument to do sweating-guarded-hot plate tests. We manufacture high-quality sweating-guarded hot plates.

More reliable test results

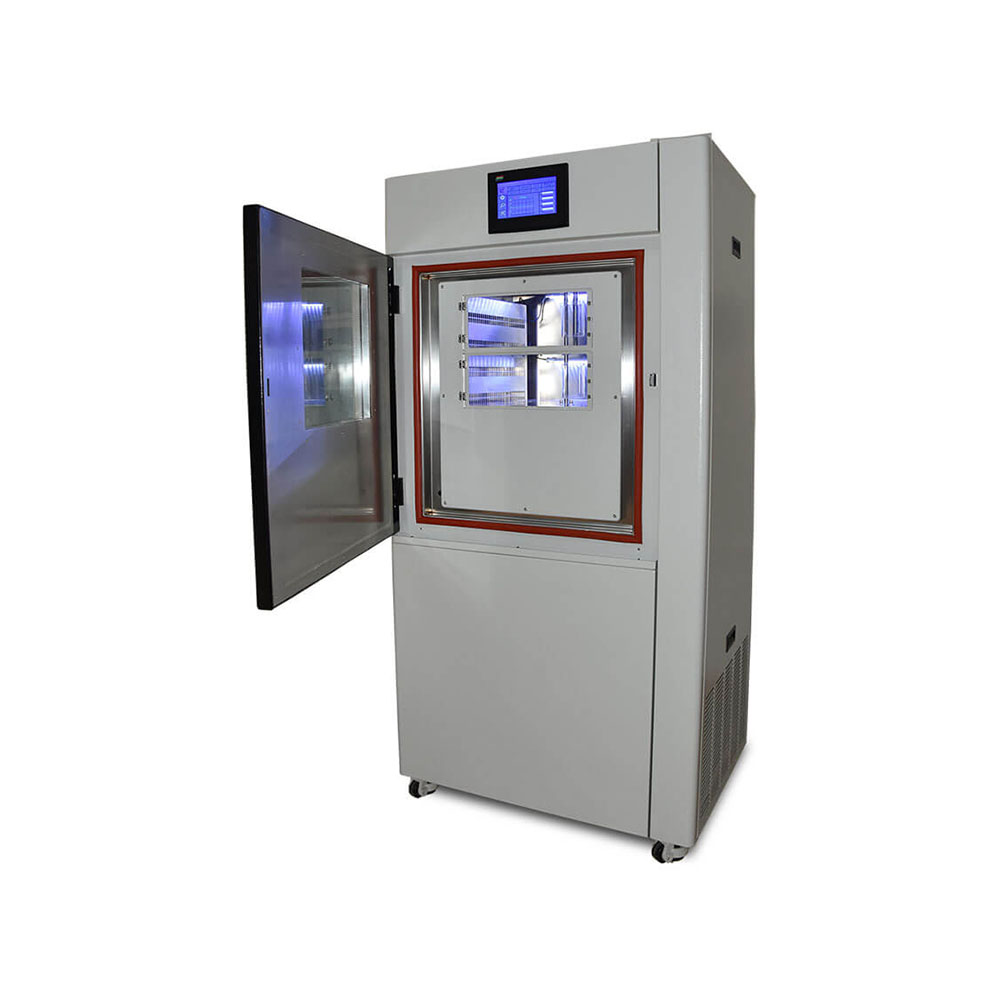

Equipped with an environmental chamber to ensure the most stringent control and monitoring of air temperature, air velocity, relative humidity, etc. Can do more objective testing on test samples.

A variety of automated systems make the test more intelligent and scientific.

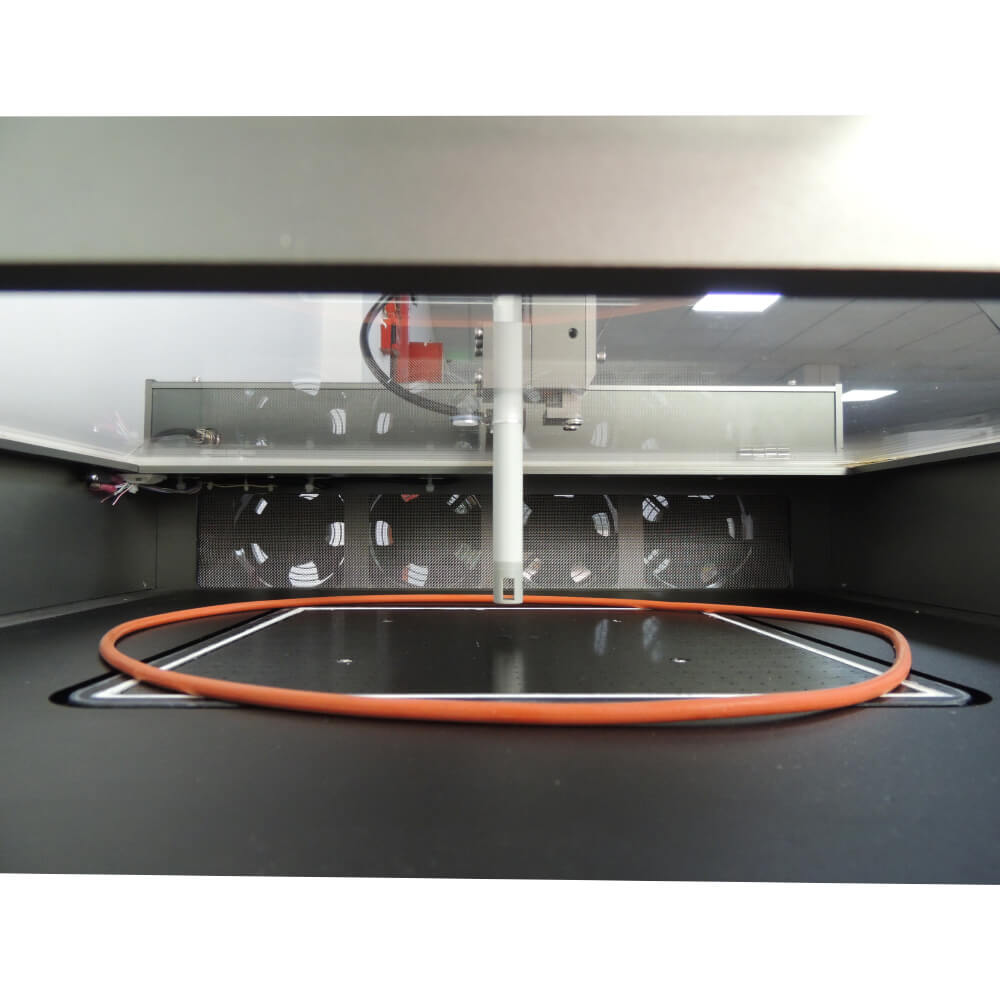

Automatic water supply, automatic drainage system, powerful water filling system, high-precision automatic platform movement system, and input test sample thickness, the test platform can automatically rise to meet the required position. Wind speed parallels the stabilization system so that the wind speed is uniform and stable so that the test results are more stable.

Friendly and convenient test software, which can directly determine and calculate each index of the specimen.

Automatic calculation of thermal resistance, water vapor resistance (evaporation resistance), water vapor permeability index, insulation value, heat loss, and display of measurement results and dynamic curves on the computer side are available.

An advanced Temperature and humidity Chamber is offered with the machine.

Note: this instrument needs a customized PC.

Application of Sweating Guarded Hotplate TF129

What kind of textiles need thermal resistance and water-vapor resistance test?

Products with general requirements for thermal performance, such as knitted underwear, cotton garments, quilts, and various kinds of wadding as padding, etc. Some coated fabrics will require water-vapor resistance testing because the resistance of coated fabrics is generally higher than that of ordinary fabrics, which affects the comfort of wearing clothes.

Thermal resistance test and water-vapor resistance test can present the ability of fabric heat and moisture exchange, can visually express the textile warmth performance, sweaty hot, and moisture comfort performance, so useful for the enterprise for fabric selection, and product positioning.

Test Principle of Sweating Guarded Hotplate TF129

The test principle of thermal resistance is to cover the specimen on the test plate, the test plate, and its surrounding thermal protection ring, the bottom of the protection plate can maintain a constant temperature so that the heat of the test plate can only be dissipated through the specimen, air can flow parallel to the upper surface of the specimen when the test conditions achieve, determine the heat flow through the specimen to calculate the thermal resistance value of the specimen.

The test principle of water-vapor resistance is to cover the test plate with a breathable but impermeable film, and after the water enters the test plate, evaporates and passes through the film in the form of water vapor, so there is no liquid water contacting the specimen. After the specimen is placed on the film, the heat flow required to keep the test plate at a constant temperature under a certain water evaporation rate is measured, and considering the water vapor pressure through the specimen, the water-vapor resistance of the specimen is calculated.

Know More about Thermal Resistance and Water-vapor Resistance

Textile – Test standards for thermal resistance and water-vapor resistance

- GB/T 11048: Testing of thermal resistance and water-vapor resistance under steady-state conditions – sweating guarded hotplate test method

- ISO 11092: Textiles – Physiological effects – Measurement of thermal and water-vapor resistance under steady-state conditions (sweating guarded hotplate test)

- ASTM F1868: Standard test method for thermal and evaporative resistance of clothing materials using a sweating hot plate

This sweating-guarded hotplate (often referred to as the “skin model”) described in this international standard is intended to simulate the heat and mass transfer processes that occur next to human skin. This test method is suitable for all types of textile fabrics, but also for coating, leather, and multi-layer composites. Additionally, we can share the ISO 11092 test methods and ISO 11092 pdfs as well.

Difference BetweenThermal Resistance (RCT) and Water-vapor Resistance (RET)

- RCT: Thermal resistance determines if the fabric holds in heat. The higher the value obtained, the better the insulation. Rct (m²·K/W)

- RET: Water-vapor resistance determines a fabric’s ability to allow water vapor (perspiration) to pass through it. The lower the value obtained, the more breathable the fabric. Ret (m²·Pa/W)

Rct0 test, sample Rct test, Ret0 test, and sample Ret test can be performed on TESTEX Sweating Guarded Hotplate TF129.

Why Choose TESTEX Sweating Guarded Hotplate TF129

Strictly meet standards:

All data for TF129 meet the standard parameters, for example, ISO 11092 and ASTM F1868.

Consistency with international third-party laboratories:

The test data are comparable to the test results obtained by well-known international third-party laboratories.

High reproducibility:

Whether is the same set of samples, or different machines of the same model, after multiple tests, the results are consistent.

Longer service life:

TESTEX makes prototypes and then subjects them to rigorous reliability testing in a variety of environments to ensure achieve the expected service life.

Longer service life

For all the Sweating Guarded Hotplates manufactured by TESTEX, before mass production, prototypes are made and required to pass the strict Reliability Test. This means testing under challenging conditions such as high and low temperatures, high speeds, and high loads to ensure an expected service life of no less than 8 years.

User-friendly transparent warranty policy

Textile testing machines, 14 months free warranty (12 months normal warranty time + 2 months shipping time). Besides, all spare parts, have 3 months free warranty.

We provide full life-cycle support for sweating guarded hotplate TF129, as well as a series of thermal resistance test equipment and thermal resistance test service, please feel free to contact our service team with any questions you may have. The thermal resistance and moisture resistance test of fabric is very important to identify the comforts of textiles.

5 reviews for Sweating Guarded Hotplate TF129

You must be logged in to post a review.

Why We Need the Thermal Resistance Test?

When people wearing clothes in cold or hot climates, the temperature of clothing, especially close-fitting, varies with the temperature of the skin. People should choose suitable clothes to ensure comfort, or at least in adverse weather conditions to protect the human body. The heat transfer property of fabric can ensure the comfort of clothing, for example, the clothing with high thermal resistance has a better function of preventing cold, while the clothes with low thermal resistance can give a cool feeling. Therefore, testing the thermal resistance of fabrics has an important reference for improving people's clothing comfort.

Thermal Resistance Test Principle

The sweating guarded hot plate instrument produced by our company adopts the constant temperature method. Place the sample to be tested on an electric hot plate which has good thermal insulation at all the other surfaces. Transfer heat to an electric heating plate so that it reaches constant temperature state, and test the heat needed to maintain the constant temperature of the electric heating plate. This method has been adopted by ASTM as the standard number ASTM D1518.

Sweating Guarded Hot Plate Test Method(Thermal Resistance Test Method)

Assemble the instrument, install SGHP software according to instructions, connect with thermal resistance instrument through network signal, and prepare for the test.

The RCT0 test is used to express the basic parameter of a machine. The value of Rct0 will be used to calculate the final RCT value of a sample. Rct0 test should be done when the machine stopped for a long time or the environment changed great.

Cut the sample as 50 cm x 50 cm, and pretreat it according to the standard requirements. Place the treated sample on the surface of the test area. If the thickness of the sample is more than 1 mm, then adjust the height of the wind speed sensor so that the height between the sample and the sensor is about 15 mm. According to the standard requirements to set the temp and humidity and then start the test until the testing environment is stable. Record the test results and calculate the final RCT values of the sample.

Daily Maintenance

1 Keep the machine clean: Clean the surface of the test plate and the dust of the air of exhaust grid by using the towel.

2 If the Ret test is finished and another Ret test will be run in next day, then open the safety cover and open the door of the conditioning chamber, the water will be evaporated from inside of the machine, and prolong the service life of the machine.

3 If the conditioning chamber will not be used for a long time, please drain off the water of the conditioning chamber.

The working principle of the Sweating Guarded Hotplate

The Sweating Guarded Hotplate is to evaluate the thermal resistance and water-vapor resistance of textiles. A waterproof and breathable film is placed on top of the hot plate, and a sample measuring 0.3m x 0.3m is placed on the film. Distilled water is fed from the bottom of the hot plate, and the surface temperature of the hot plate is stabilized at 35℃ to simulate sweating in the human body. The Sweating Guarded Hotplate is placed in an environmental chamber with a temperature of 35°C, humidity of 40%, and air flow rate of lm/s. When the system is in a steady state, the evaporative resistance of the fabric is calculated by equation (3): Ret = A(Pm - Pa)/(H - ΔHe)

Where Ret is the total evaporative resistance in m2·Pa/W; Pm is the saturated water vapor pressure on the surface of the test plate at the temperature of the test plate, Pa; P is the water vapor pressure of the air in the chamber, Pa; H is the heating power, W; and ΔH is the heating power correction term, W.

A: No, it is not equipped with this option.

Q: At what humidity ranges is the machine able to run?

A: The machine is not equipped with control humidity, but Temperature & Humidity Chamber can meet your needs, with its humidity range of 25%~85% R.H.

Q: What advantages does the machine have?

A: 1. It can contact with WIFI.

- The thermal resistance and Temperature & Humidity Chamber can be used separately. And other suppliers combine the two machines into one. They must be used together.

<start="3"> - Our Temperature & Humidity Chamber is made by a professional factory, which is more accurate. The ITS (Intertek testing service) bought this machine from a famous company, whose price is triple than ours. The test results from this machine are not precise because the machine is made by the company himself. Finally, he turned to us and bought a new one. We only do what we are good at.

jack ding –

This is the big investment for our lab, but it worth it, make our testing smooth and efficient

Adelaide Graham –

It’s worthy.

Mabel Electra –

Works perfectly, instruction manual was easy to read and understand.

Kyle Thompson –

That is very stable, and I like to communicate with professional staff like Lily.

testextextile –

Thanks. All staffs in TESTEX are professional.

Fanny Windsor –

The guarded hot plate apparatus price is reasonable and help us a lot.Recommend !