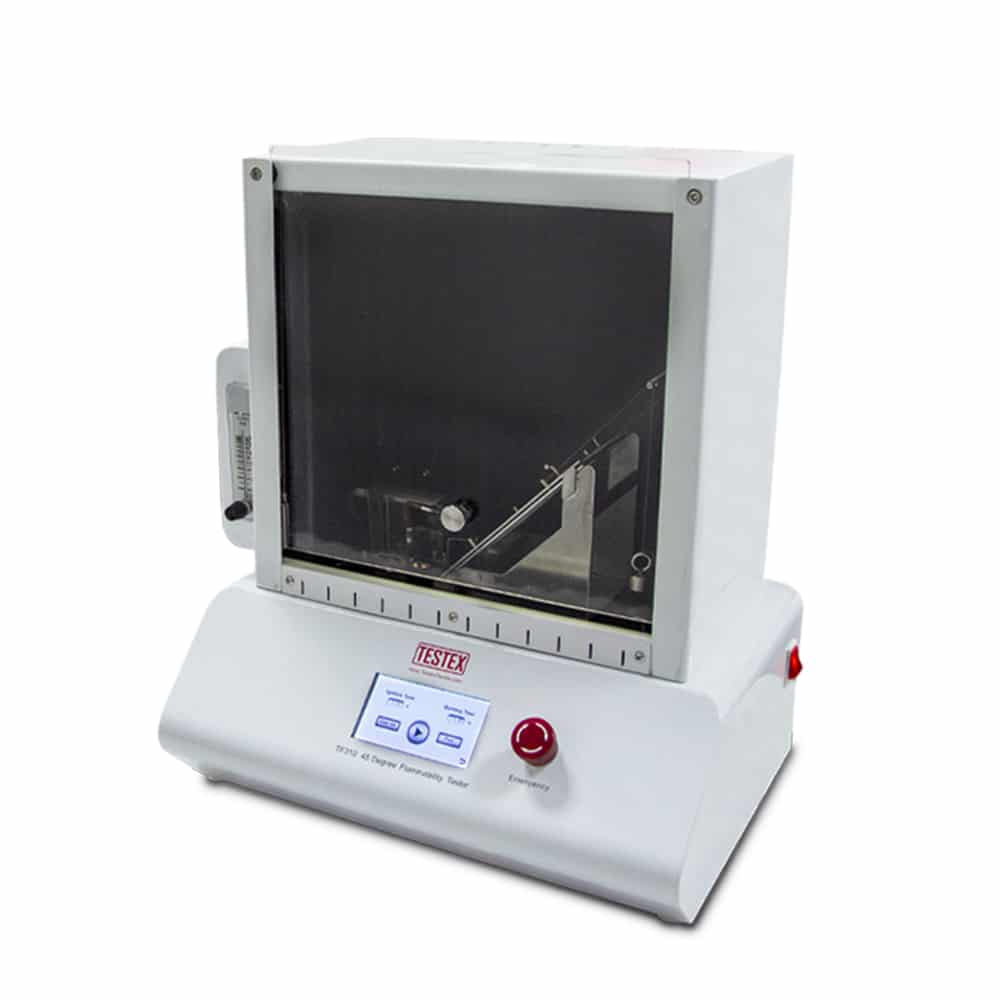

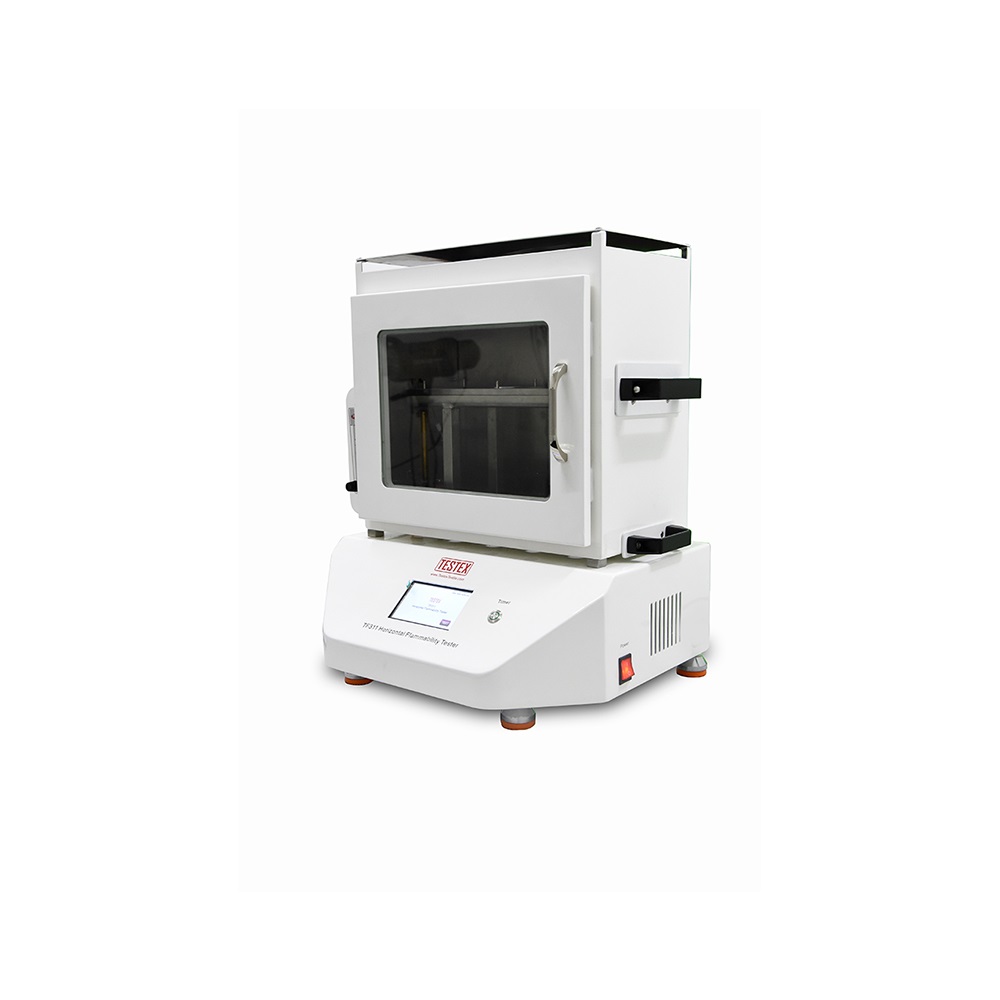

NFPA 701-1 Flammability Tester TF320

NFPA 701-1 Flammability Tester, to determine the ignition resistance properties of draperies and other hanging fabrics according to test method NFPA 701#1. NFPA 701-1 Flammability Tester complies with NFPA 701-2004 Test Method 1, etc. NFPA 701-1 Flammability Tester can give you a hand when you do NFPA 701 test.

Description

Application

NFPA 701-1 Flammability Tester, to determine the ignition resistance properties of draperies and other hanging fabrics according to test method NFPA 701#1, and it is suitable for single-layer or multi-layer fabrics, but not suitable for fabrics with density larger than 700g/m2 (21oz/yd2).

Specifications

- Open-type burning chamber structure;

- Chamber body in calcium silicate board, and wrapped by stainless steel external;

- Standard Meker laboratory burner;

- Record burning time automatically;

- Auto-ignition mode to avoid operative error;

- Timer accuracy up to 0.1second;

- Provide with a standard specimen holder.

Weight

| 100 kg |

Power

| 220/110 V | 50/60 Hz |

Dimensions

| Length: 900 mm | Width: 510 mm | Height: 720 mm |

Standards

| NFPA 701-2004 Test Method 1 |

4 reviews for NFPA 701-1 Flammability Tester TF320

You must be logged in to post a review.

Test Range

Test method 1: suitable for table skirt, all kinds of curtains (curtain, stage curtain, shade cloth), tablecloth, decorative curtain, etc., it is suitable for testing single-layer fabric and multi-layer curtain, not suitable for samples with local density greater than 700g/m², for example, ethylene coated fabrics shall be tested with test method 2.

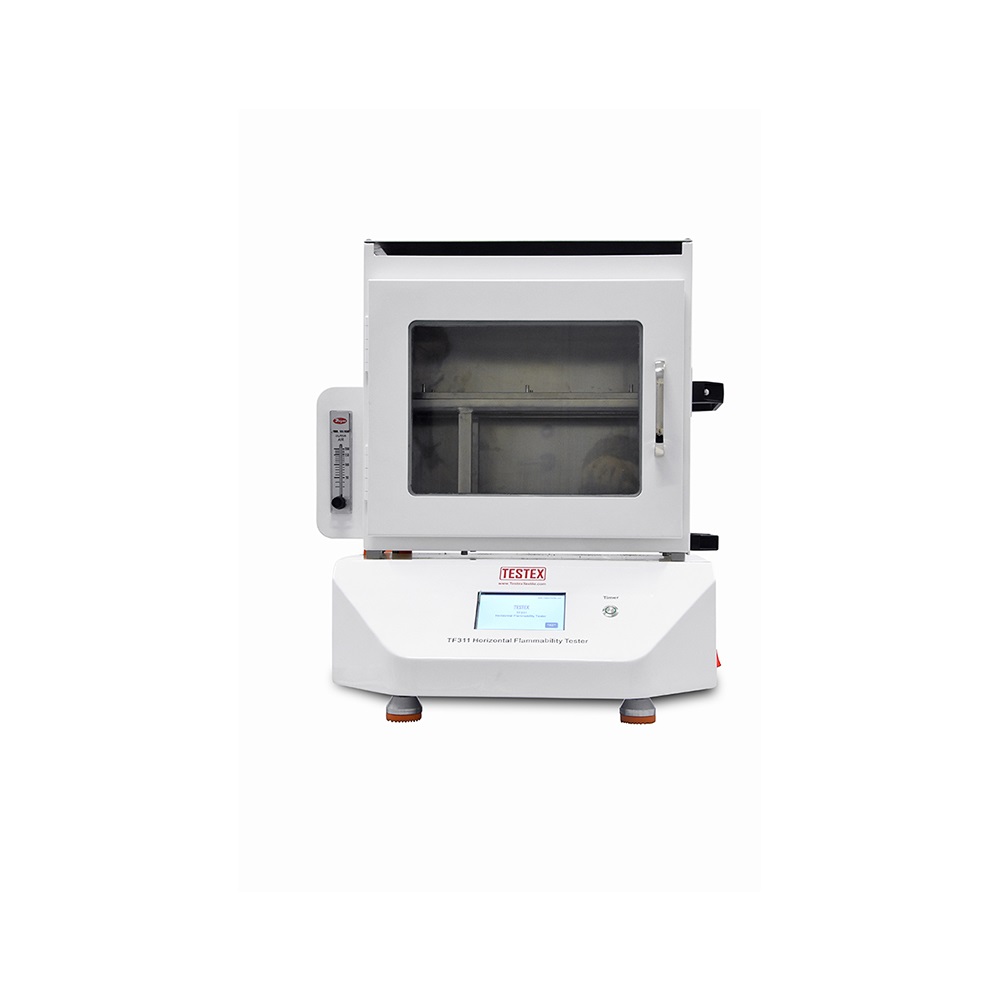

Test method 2: suitable for fabric with flat surface and area density greater than 700g/m², including multi-layer fabric, film, plastic curtain, etc., suitable for ethylene coated fabric, suitable for shade, tent, waterproof cloth and similar building fabric banner.

Test Requirements

Test method 1

1 After removing the ignition source, the combustion time of the specimen shall not exceed 2 seconds.

2 The average mass loss of the sample burning shall not exceed 40 percent.

Test method 2

1 After removing the ignition source, the combustion time of any single sample shall not exceed 2 seconds.

2 The burning time of any single sample shall not exceed 2 seconds after dropping to the bottom of the test box when burning test.

3 The standard for the scorching length of the folded specimen depends on the type of specimen.

The NFPA 701-1 flammability tester is designed according to the requirements of test method 1, the general requirements and test steps of the test method are as follows.

General Requirements for Testing

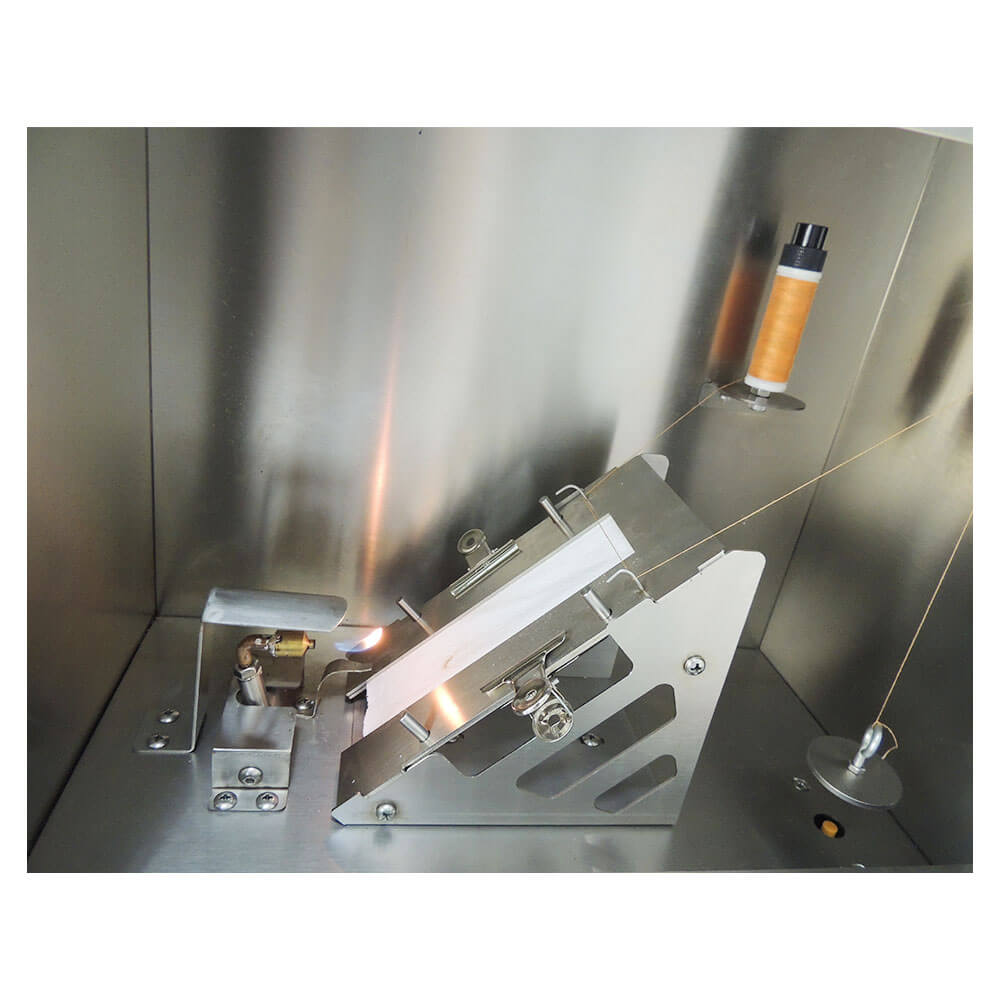

1 The test sample consists of one or more layers of fabric that need to be suspended vertically from the bar near the rear of the open test cabinet.

2 Apply a specific flame to the center of the bottom edge of the sample for 45 seconds and remove it.

3 The sample needs to burn until the flame extinguishes itself, and the sample is no longer damaged to ensure that the quality does not change.

4 Remove the sample from the bar, adjust the room environment, and weigh again.

Test Step

1 Instrument adjustment and sample preparation: before testing, adjust the air ventilation open of the burner base and adjust the air velocity and methane velocity according to the test requirements. Adjust the pressure gauge so that makes the flame height meets the requirements. Cut 10 samples according to the standard size, if multilayer fabric needs to be tested, stitched together.

2 Sample fixing: fix the short edge of the sample to the rod, make the sample naturally perpendicular with a clip, and let the surface of the fabric face the wall or window in normal use face the rear of the test box.

3 Burner placement and preparation: the burner should be located at the position where the distance from the sample surface 25±2mm. Make the central axis horizontally perpendicular to the bottom of the central line of the sample by moving the base and adjusting the angle of the burner, and open the exhaust fan.

4 Test: the test shall be conducted within 2 minutes after the sample is taken out of the forced ventilation box. The sample was exposed to the combustion flame for 45±1s, and then close the airflow by using the control valve on the burner. The exhaust fan remained open throughout the test.

5 Record the test results: record the combustion time of the sample after the airflow is closed and the burning time of the material falling to the bottom of the test box, observe the burning intensity of the sample, the odor produced, and so on. Brush the ash and charred parts of the sample lightly with the wire brush, remove the sample from the clamp bar and weighed, calculate the result according to the formula.

[contact-form-7 id="16355" title="Inquiry"]

Alvin Price –

Good. Price is reasonable.

Boris Malthus –

Easy to use. Seems accurate. Nice price. I like it.

Malcolm Katharine –

Awesome flammability tester! Awesome manufacturer!

testextextile –

Thanks for your satisfaction.

Alfred –

Gran producto.