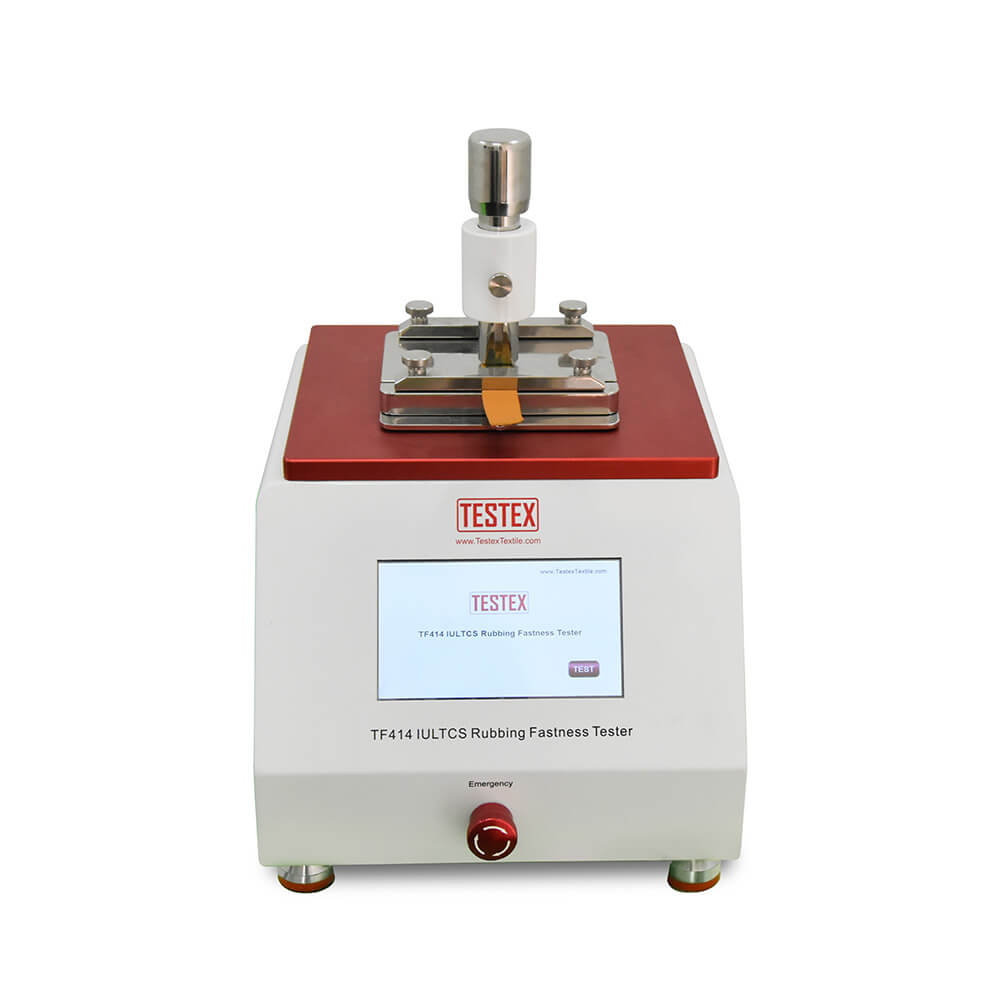

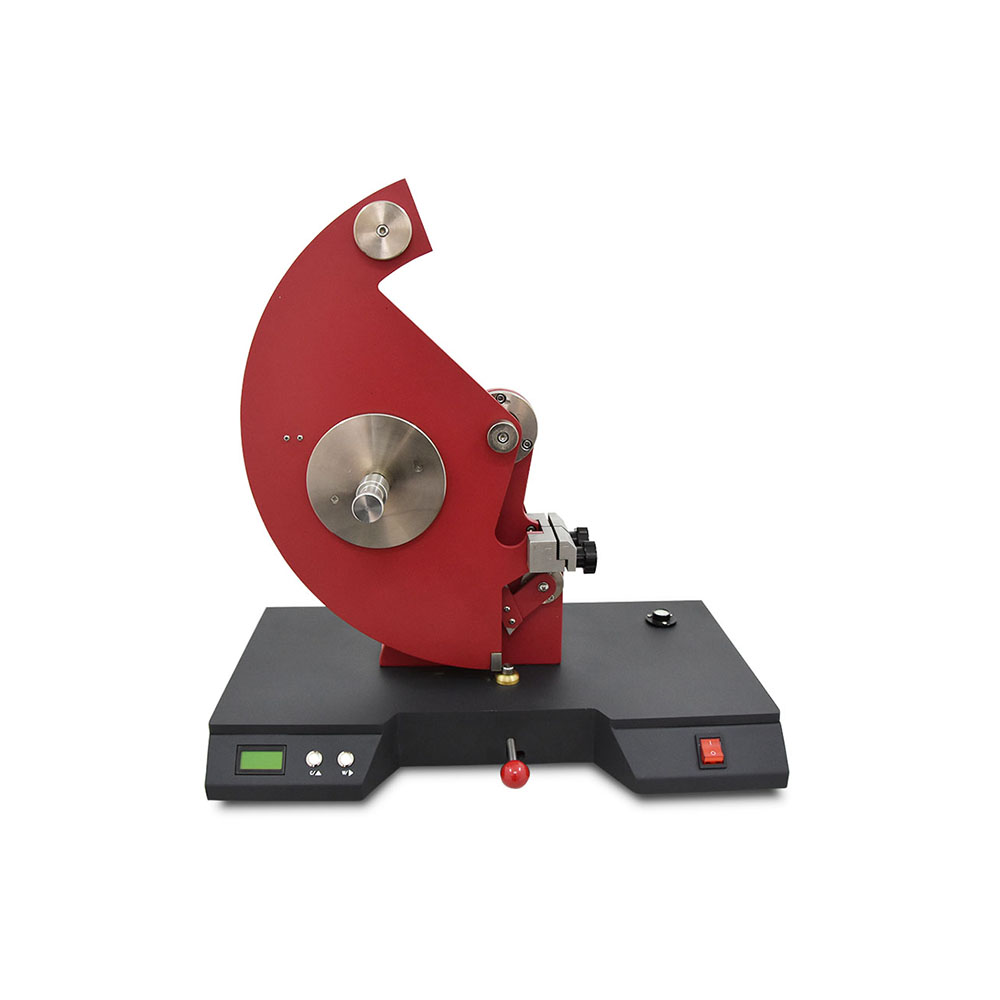

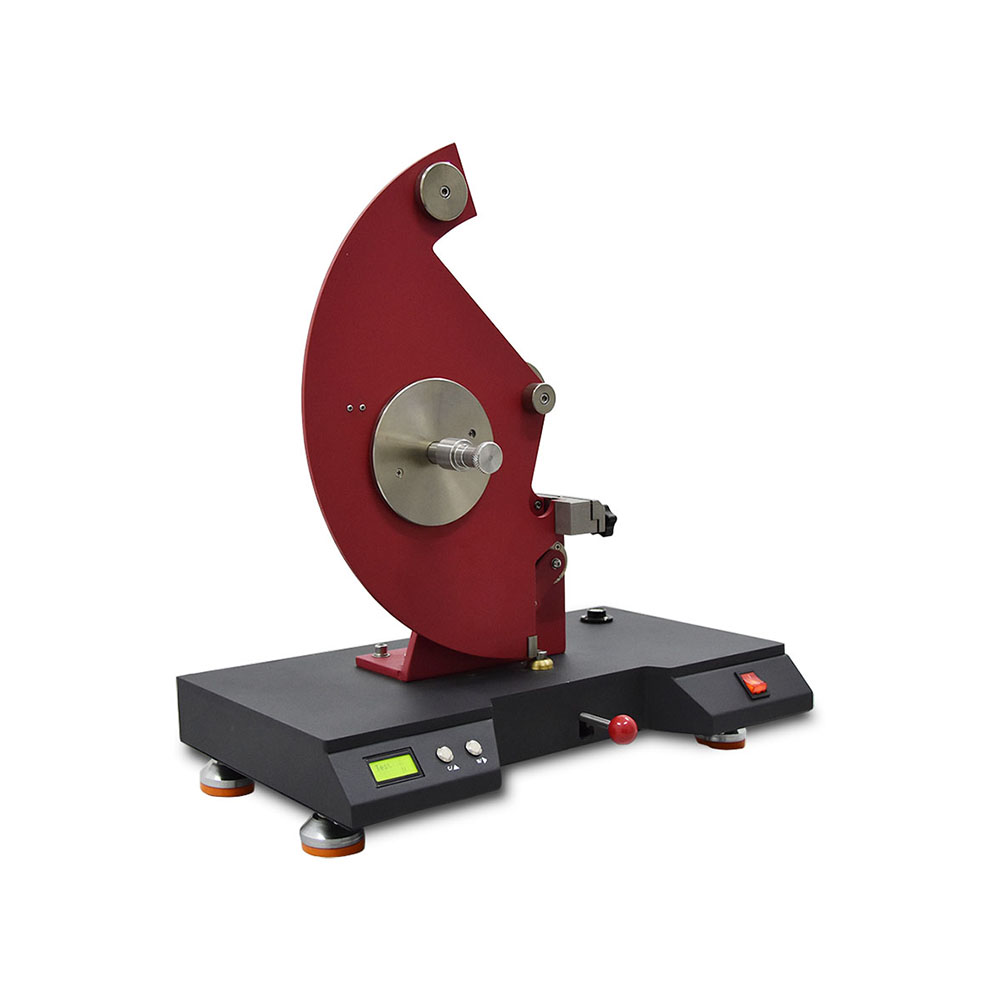

IULTCS Rubbing Fastness Tester TF414

Rubbing Fastness Tester, to determine the color fastness to rubbing. IULTCS Rubbing fastness Tester complies with ISO11640, EN 344, SATRA PM 173, etc. You can contact us if you have any problems when you do rubbing fastness test.

Description

Application

IULTCS Rubbing Fastness Tester, designed to carry out a rub fastness test on the surface of leather to determine the amount of ‘marring’ of the leather surface or the finish and to assess the amount of colour transferring from the sample to the rubbing pad under dry or wet conditions.

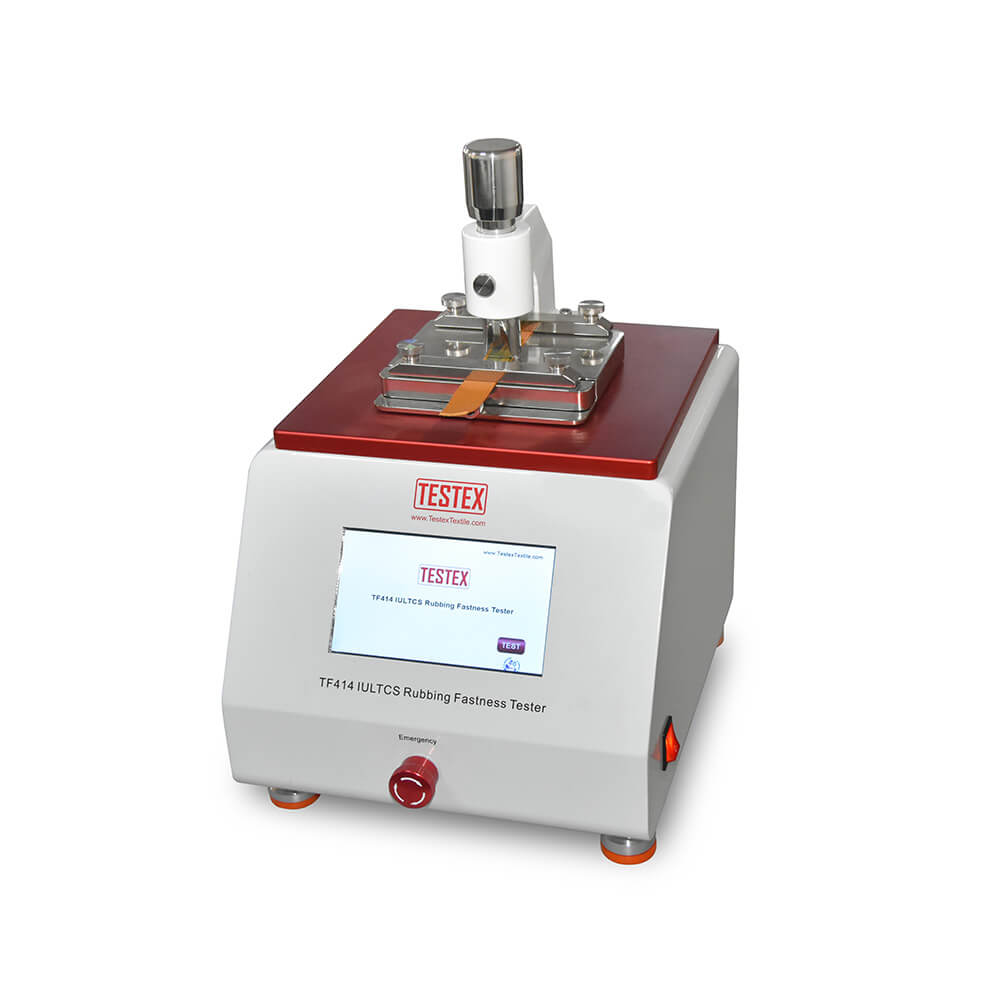

The unique design of IULTCS Rubbing Fastness Tester allows reliable and stable test result.

Impact appearance and construction design offers a good shape and convenient operation, also allows a long life time without repairing.

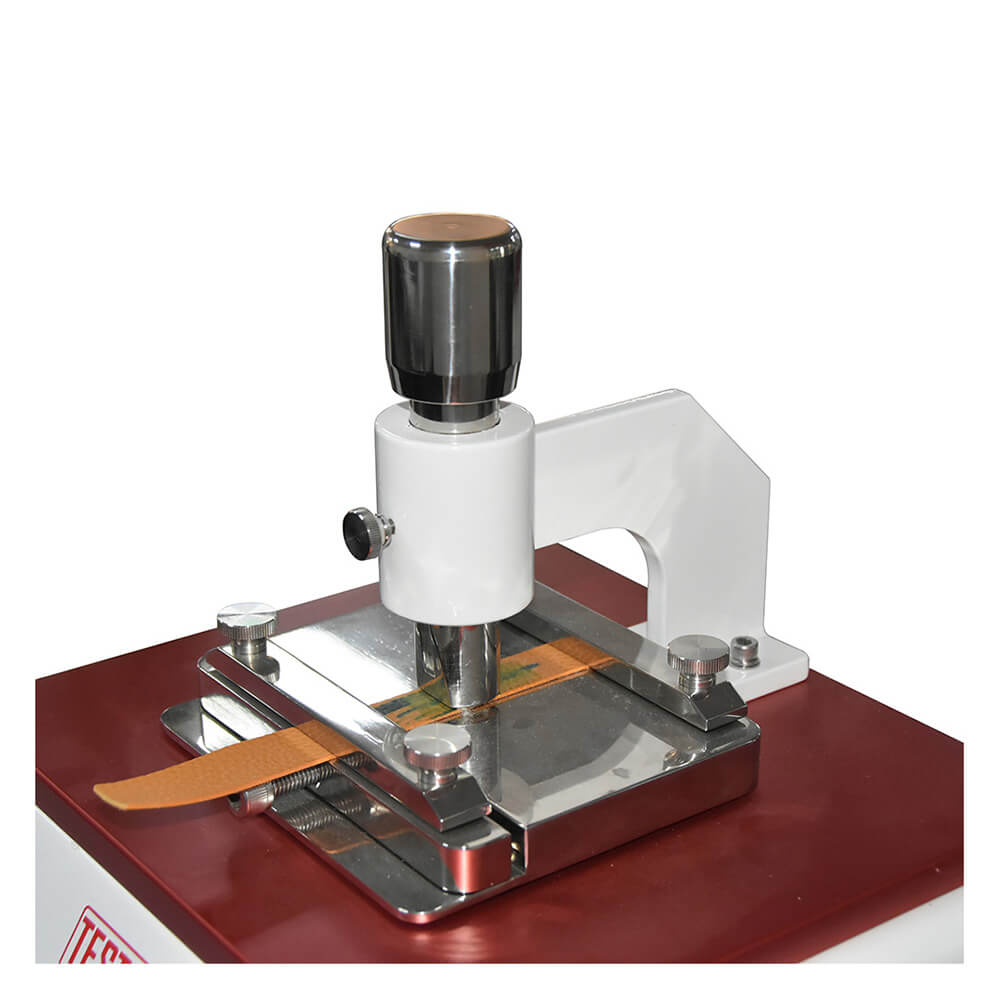

Available with a piece of 500g loading weight, thus allows a test with 500g or 1000g loading.

Equipped with an extension device so samples can be extended at a required rate.

Two models of single and double test position are offered.

Specifications

- Rubbing finger: 500 +/- 25 g(or 1000g by adding a load mass)

- Loading weight: 500 +/- 10 g

- Dimension of base of finger: 15 x 15 mm

- Specimen: 120x20mm

- Rubbing stroke: 35 ~ 40 mm

- Speed of rubbing: 40 +/- 2 cycles/min

- Counter: 1-999,999 times, automatically stops

Optional order

White Rubbing wool felts 1000pcs / pack

Black Rubbing wool felts 1000pcs / pack

Weight

| 25 kg |

Power

| 220/110 V | 50/60 Hz | 3 A |

Dimensions

| Length: 320 mm | Width: 380 mm | Height: 500 mm |

Standards

| ISO 11640 | ISO 17700 Method A | QB/T 2537 |

10 reviews for IULTCS Rubbing Fastness Tester TF414

You must be logged in to post a review.

Test Principle

Use a prescribed felt to perform a reciprocating friction test on one surface of the leather under the specified pressure, and test the specified number of times. Compare the color changes of felt surface and leather surface with gray sample card to determine the grade and record any visible change or damage to the leather surface. The instrument is suitable for all kinds of leather.

Test Steps (Standard QB / T 2537)

1 Cut the sample according to the standard, and adjust it.

2 Fix the air-conditioned specimen on the test table and draw 10% along the friction direction. If the specimen cannot stretch 10%, stretch the specimen to the maximum allowable elongation. If the sample is not stable during friction after 10% elongation, continue to stretch the specimen until the specimen cannot be elongated. Record the above two cases in the test report.

3 Test the general leather sample, loading load, so that the total weight of the test head is 1000g. Suede leather and similar leather, due to the effect of larger friction, the test load is not loaded, the total weight of the test head is 500g.

4 Fasten the prepared test felt to the test head so that the test head is in horizontal contact with the leather sample. Then set the friction times and start the friction test.

5 After the test, remove the sample and felt, evaluate the color change of the friction part of the sample and the contamination of the felt. Record the test results.

How to Ensure the Accuracy of the Test Results of the Color Fastness to Rubbing?

1 Before testing, we should carefully check whether the friction surface of the friction head is smooth, otherwise, the stain on the friction cloth will appear abnormal phenomena of different colors inside and outside.

2 It must be reliable and cannot be loosened when the friction cloth is fixed on the friction head, otherwise, the color spot of the friction will not be round.

3 The surface of the friction head should always be in relatively parallel contact with the surface of the specimen. When the friction head is improperly installed or the thickness of the specimen varies greatly, both contact surface will be changed. At this time, the grommets on the friction head should be appropriately increased or decreased to adjust the position of the friction head.

4 When the friction cloth is fixed on the friction head, the friction head should be carefully placed on the specimen so as not to increase the stain degree accidentally. This is especially true for wet friction tests.

How to test the rub fastness of the leather surface? Through this article, I think you might have got some information. If you want to know more, please contact us. As a professional supplier of textile instruments, we are committed to continually improve the user experience, TESTEX Textile Testing Equipment is a reliable choice for testing textile quality.

[contact-form-7 id="16355" title="Inquiry"]

A: Yes, we do. The IULTCS Rubbing Fastness Tester TF414 is exactly what you want.

Q: Do you have a device for testing the resistance of a material (leather) to wet friction (Russian GOST 13869-74 standard)?

A: No, we haven't this standard.

Victorf –

Efficient rubbing fastness tester, stable and easy to use

Karen Chapman –

Timely delivery, everything one needs in one neat package. Recommend!!

Kenneth Gibson –

Works great and it’s reliable. Thanks manufacturer.

Veronica Keats –

The tester works well

Theobald Dewar –

The rubbing fastness tester is really help.Will return to buy.

Malcolm Conrad –

Geart rubbing tester. Recommend this manufacturer.

Rosalind Veblen –

Good price, good service. Recommend this suppiler of IULTCS Rubbing Fastness Tester.

Tony –

pedido recibido ,bien embalado, sin problemas

Allen Edward –

Perfect fast shipping thank you

Rachel Franklin –

Thanks for fast delivery