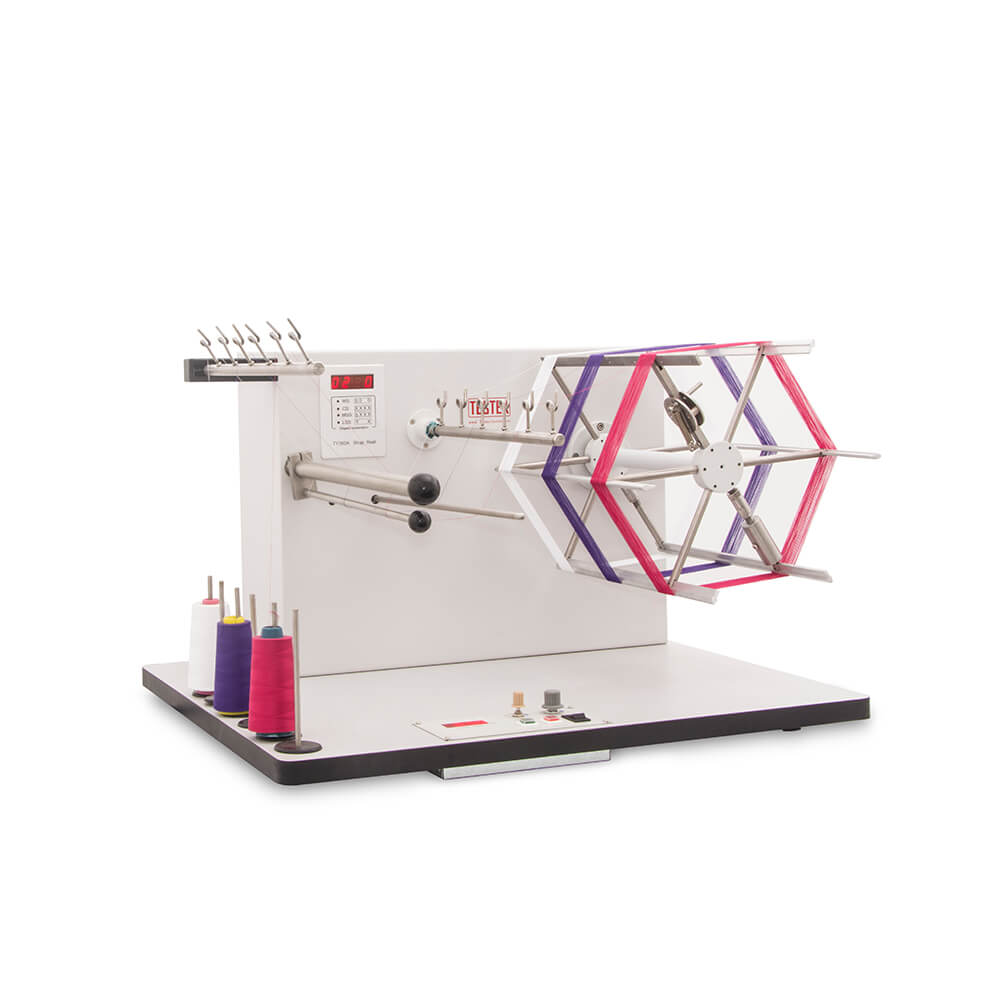

Fiber Fineness & Composition & Content Analyser TB300

Fineness & Content Analysis System, or fibre analyzer, to determine the fineness of fiber and analyze the content and surface feature of textile fiber. The fineness Analysis System complies with AATCC20, ISO 137, ISO 17751, etc. Fiber testing&analysis are very important for textile factories or companies.

Description

Fiber Fineness & Composition & Content Analyser TB300 for determining the fiber fineness and analyzing fiber content, fiber composition, such as cotton, wool, man-made fiber, etc. It is based on digital image technology, which means that the operator selects the fibre object and then the fibre analysis system automatically measures the fibers and obtains statistical results. It is more advanced than the crude fiber analysis machines in the market.

Fiber Fineness Test

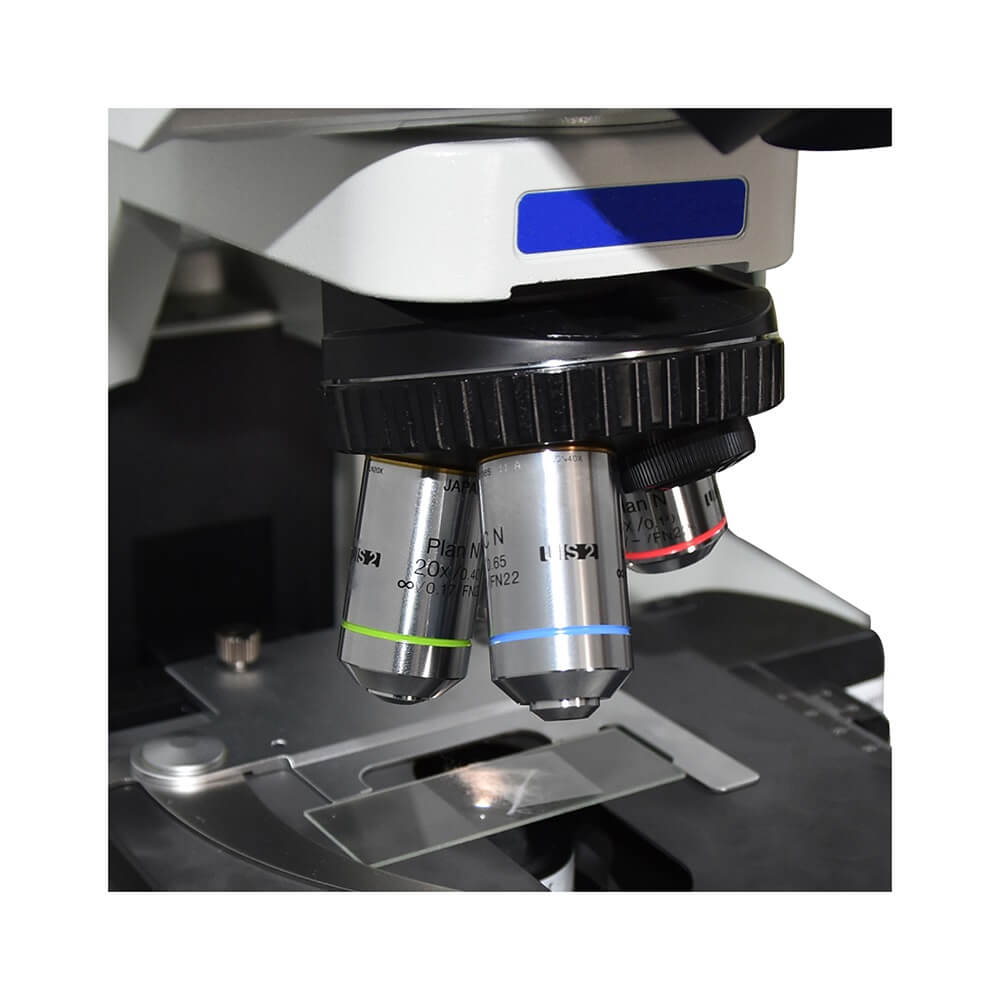

Use the fiber fineness tester to magnify the fibers and project them onto the screen. Then select the fiber object and the system will automatically calculate the fiber fineness. It is a kind of high efficient fiber fineness measurement.

Fiber Composition Test

Use the microscope to magnify the fibers and project them onto a screen, then observe the morphology of the fibers. As different fibers have different morphological characteristics, it is possible to determine the composition of the fibers simply by comparing them with standard fiber photographs.

Fibre Content Test

Test the fiber composition first, then test the fiber diameter or cross-sectional area, as well as the number of fibers. Finally, the software calculates the fiber content automatically.

Note: This system needs a customized PC.

| Model | Standards | Function | Standard configuration | Power, Weight, Dimensions |

| TB300A Fiber Fineness Analyser | ISO 137 | Fiber Fineness Test | Fiber fineness software microscope Camera Computer | 220/110V, 50/60Hz 70 kg 600 x 400 x 600 mm (L x W x H) |

| TB300B Fiber Fineness & Composition & Content Analyser | ISO 137 ISO 17751-1 | Fiber Fineness Test Fiber Composition Test Fiber Content Test: By checking the fiber longitudinal to test the fiber content. | Fiber fineness & content software microscope Camera Computer | 220/110V, 50/60Hz 70 kg 600 x 400 x 600 mm (L x W x H) |

| TB300C Fiber Fineness & Composition & Content Analyser | AATCC 20/20A ISO 137 ISO 17751-1 | Fiber Fineness Test Fiber Composition Test Fiber Content Test: By checking the fiber longitudinal and cross section to test the fiber content. | Fiber fineness & content software microscope camera Computer | 220/110V, 50/60Hz 70 kg 600 x 400 x 600 mm (L x W x H) |

Fiber Analysis – Principle of Microscopic Observation Method

Microscopic observation is a common method of analyzing fibers. Analysis of fibers by magnifying them using a microscope and observing their longitudinal and transverse morphology at certain magnifications.

Natural fibers have their own unique morphological characteristics, such as the natural curl of cotton fibers, the scales of wool, the transverse knots and vertical patterns of hemp fibres, the triangular cross-section of silk, etc. Natural fibres are therefore relatively easy to distinguish. Among the chemical fibres, viscose fibres have a circular cross-section with serrated edges and a skin-core structure, which makes them easy to distinguish from other fibres. However, chemical fibres such as polyester, acrylic, and nylon are easily confused under the microscope and can only be tested using other methods.

Why is Fiber Fineness Important?

Effect of fiber fineness on fiber, yarn, and fabric

Uneven fineness can lead to uneven yarns and yarn defects, but on the other hand, having a certain density of foreign threads is beneficial for the formation of certain qualities of the yarn.

①For the fiber itself

The thickness of the fiber will affect its specific surface area SS, the adsorption properties of the fiber, and the dyeing properties.

(b) Coarsening of the fibers, which increases the bending stiffness of the fibers, increases the point contact area, and the fibers become stiff and sticky to the touch and cold.

Uneven fineness between fibers causes differences in the mechanical properties of the fibers.

Differences in fineness within the fiber can lead to mechanical weakness of the fiber knots.

② Influence on yarn quality and spinning process

Relationship with yarn strength The finer the fiber, the higher the yarn strength, all other conditions being equal.

The finer the fiber, the more uniform the yarn is, all other conditions being equal; the finer and more uniform the fiber, the finer the yarn can be, provided that the yarn quality is maintained.

Relationship with the spinning process The finer the fiber, the easier it is to twist and break during processing and produce cotton knots and short fibers.

③The effect on the fabric

The different fineness of the fiber will greatly affect the feel and performance of the fabric. Such as underwear fabrics require soft, comfortable, and can be used finer; outerwear fabrics require stiff, generally available thicker fibers.

Welcome to TESTEX – a professional textile testing instrument supplier – Fiber Fineness & Composition & Content Analyser is on sale, contact us to get a detailed price quote.

5 reviews for Fiber Fineness & Composition & Content Analyser TB300

You must be logged in to post a review.

Brief Introduction of Fiber Fineness and Content

Fineness is an important index of textile fiber and yarn. The finer the fiber, the higher the yarn strength. The fabric made of fine fiber is softer and softer. In the spinning process, spinning with fine fiber can reduce the broken rate, but the fiber is too thin and easily entangled into a knot.

Fiber and yarn fineness have two kinds, direct index, and indirect index. The direct index is the diameter and cross-sectional area, however, because the cross-section of most fibers and yarns is irregular and accompanied by cavities, gaps, and holes, it is difficult to measure the diameter and cross-sectional area. So the fineness of textile fiber and yarn is expressed by indirect index, it is customary to use a unit length of mass or unit mass to denote the fineness of the fiber.

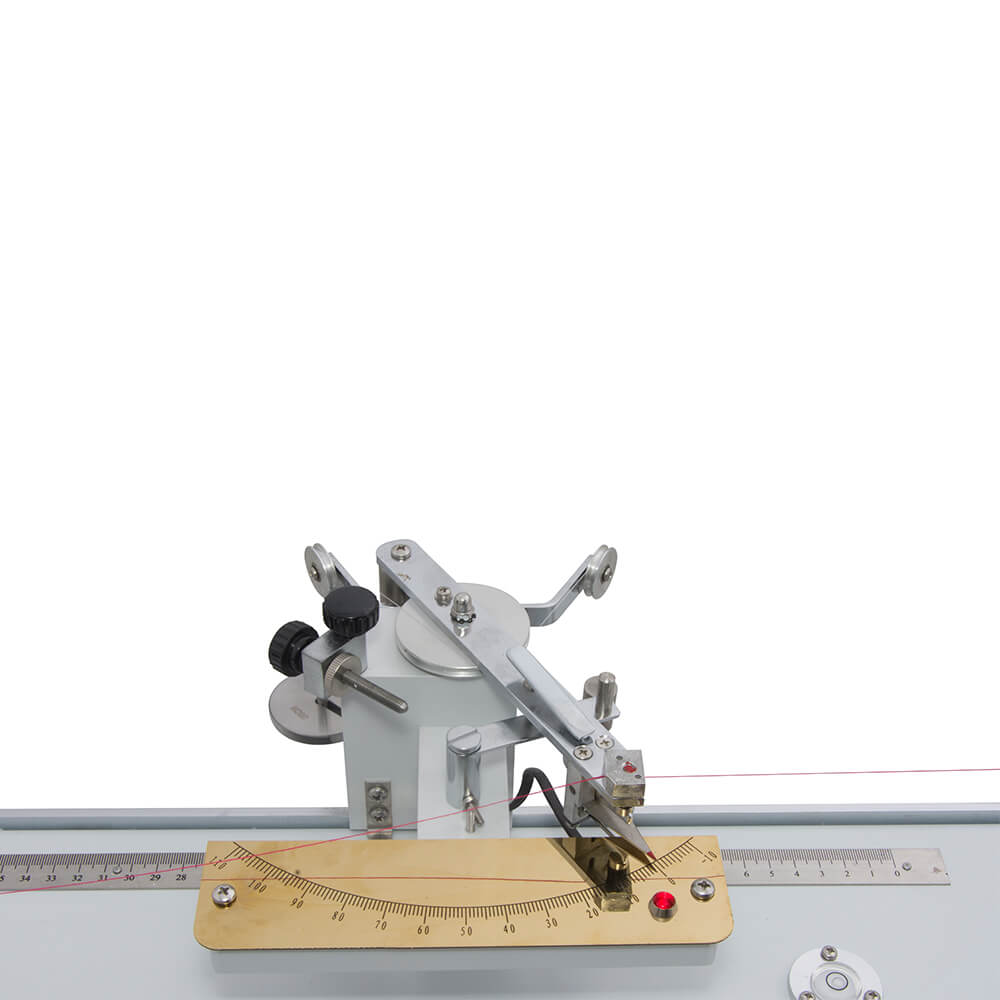

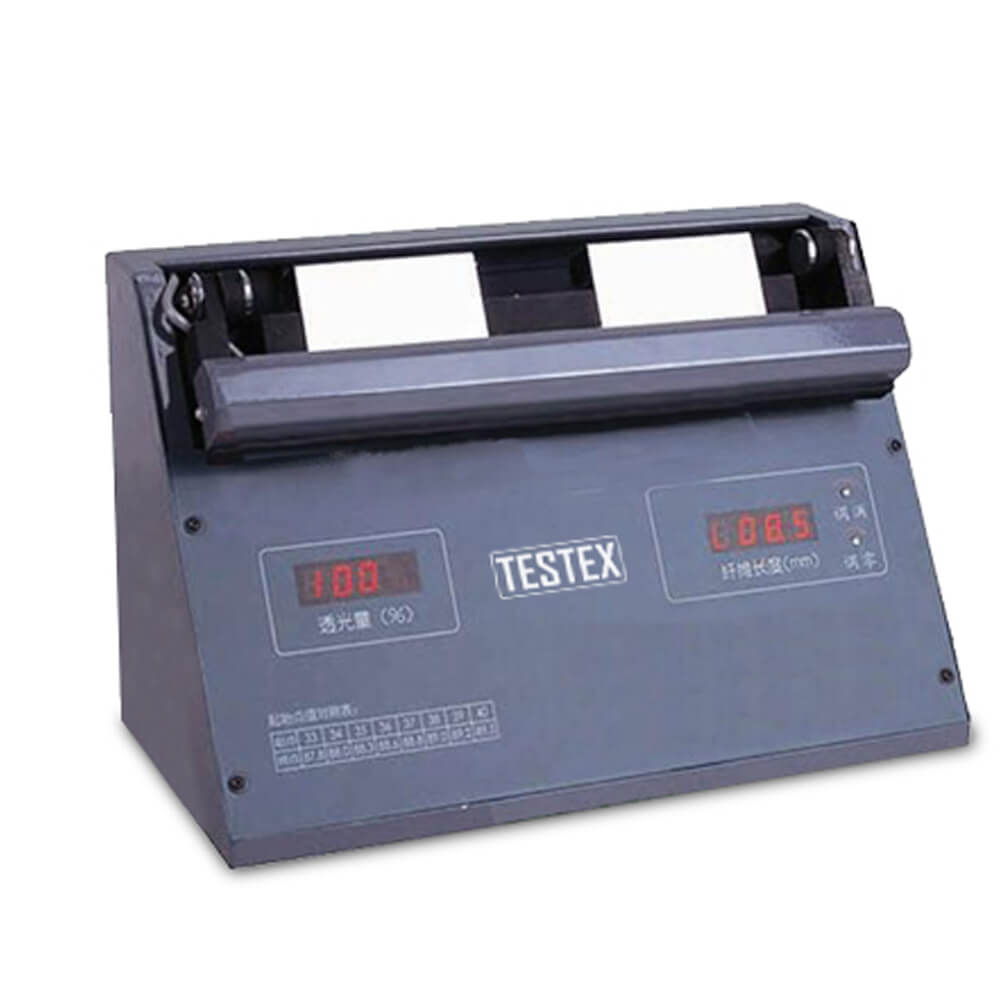

The methods of measuring fiber fineness mainly include weighing method, air meter method, projection diameter method, and single fiber vibration method. In this paper, the fiber fineness content analyzer is used to evaluate the fiber fineness and content by observing the fiber section, measuring the fiber diameter and analyzing the fiber content.

Fiber Cross-section Experiment by Fiber Fineness Analyzer

1 It is used to observe the heterogeneity and cross-section shape of all kinds of chemical fiber, special-shaped fiber, and hollow fiber, and to measure the cross-section area at the same time.

2 The fiber content of all kinds of blended products can be obtained by analyzing the transverse shape of a single fiber and measuring the area of each fiber.

3 It uses professional analysis software, output data, and provide report forms, statistical methods can be changed according to user requirements (standard to be provided)

Automatic Diameter Measurement by Fiber Fineness & Content Analysis System

1 It used for measuring the diameter of the animal fiber, chemical fiber, cotton fiber, and hemp fiber, etc., the measurement speed is fast and the operation is a simple, and less human error.

2 Increases the dynamic measurement at the diameter experiment and the content experiment, it can retain the current measurement mark.

3 It uses professional analysis software, output data, and provide report forms, statistical methods can be changed according to user requirements (standard to be provided)

Fibre Content Analysis by Fiber Fineness &Content Analyzer

1 The fiber content of various blended products can be obtained by analyzing the morphology of single fiber and measuring the diameter.

2 Provide the samples gallery of special animal fibers, chemical fiber and cotton, and hemp fibers. It is propitious for the experimenter to compare and improve their resolving power.

3 It uses professional analysis software, output data, and provide report forms, statistical methods can be changed according to user requirements (standard to be provided)

Among them, fiber content analysis, to a huge extent, the experimenter’s experience will provide the final judgment. Therefore, to ensure the repeatability of the test results, inspectors must observe more at work. Intensify the exchange of testing techniques, and frequent experimenting will help improve the accuracy of test results.

[contact-form-7 id="16355" title="Inquiry"]

Arif –

Require microscope quotation

Chris –

It works well, very good.

Hunter Wordsworth –

Goods Received. It looks perfect!

Bergen –

Eine glückliche Verhandlung!

Carter Adolph –

This machine has great performance in analyzing the content and surface feature of blended fiber. Soooo NICE!