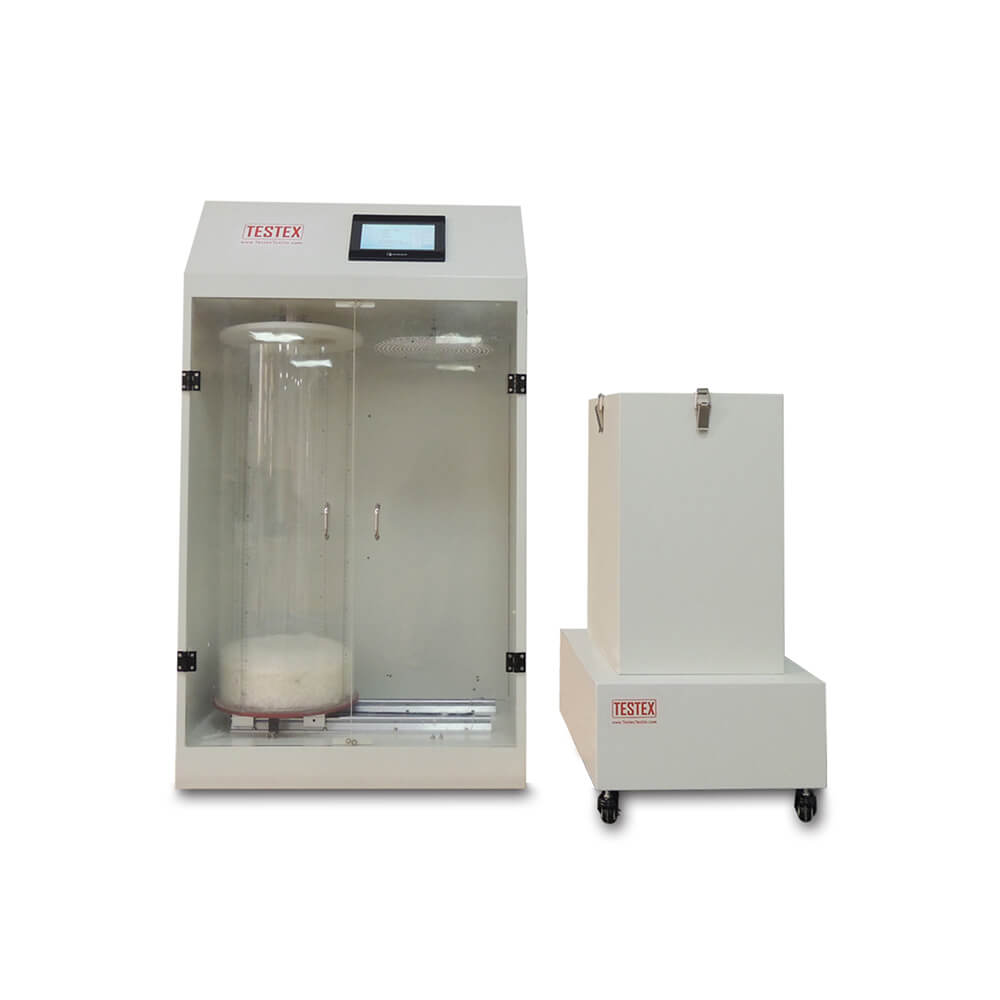

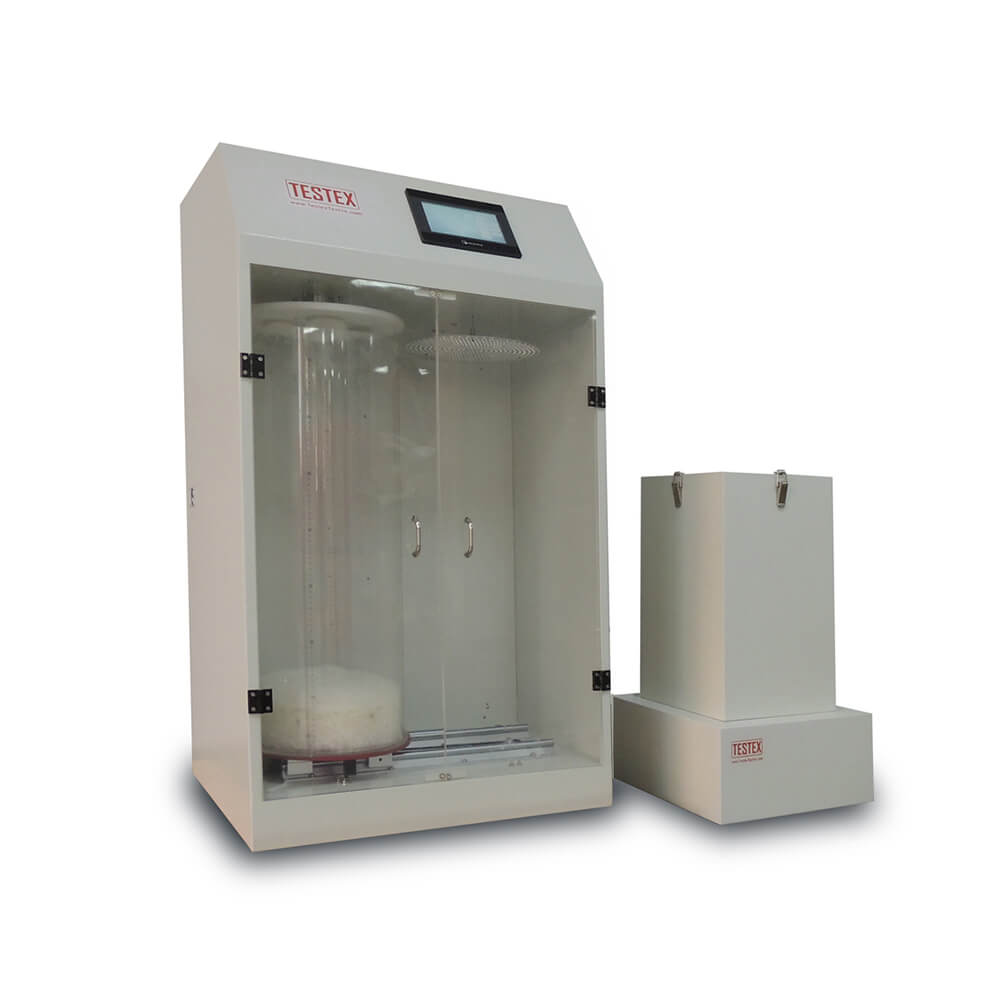

Feather & Down Filling Power Tester TF135

Feather & Down Filling Power Tester, to determine the filling power (massic volume) of feather and down.

Filling power as one of the important indicators of feather down quality, is the elasticity of down products, the concentration of warmth performance, the greater the filling power , the better the warmth performance of feather&down products.

Feather & Down Filling Power Tester complies with BS EN 12130, GB/T 14272, GB/T 10288, etc.

Description

Features of Feather & Down Filling Power Tester TF135

1. Quick and convenient: a single-chip controller for automatic control of the testing process, just put the sample into the test cylinder and start the instrument, and after about 10 minutes directly get the test results.

2. Accurate testing: DC reducer motor drive is decisive in accurately measuring the volume of feathers.

3. Reliable results: automatic blowing system is used to guarantee that the feather feathers are in a uniform state so that the data of each measurement has good reproducibility.

4. Environment-friendly: Independent filter system design ensures that feathers do not fly around and avoid polluting the environment.

What is the Down Filling Power Test?

Filling power is one of the most important indicators of down feathers and is the main expression of elasticity and warmth. The filling poser test is expressed as the volume of a certain number of down samples passed through a specified container under a certain pressure. The greater the filling power, the greater the amount of still air in the container. The layer of still air is a good insulating layer, so the greater the filling power of the down, the better the warmth of the down product.

Application of Feather & Down Filling Power Tester TF135

Fill power testing is an important element of down testing and is applied to feather and down products.

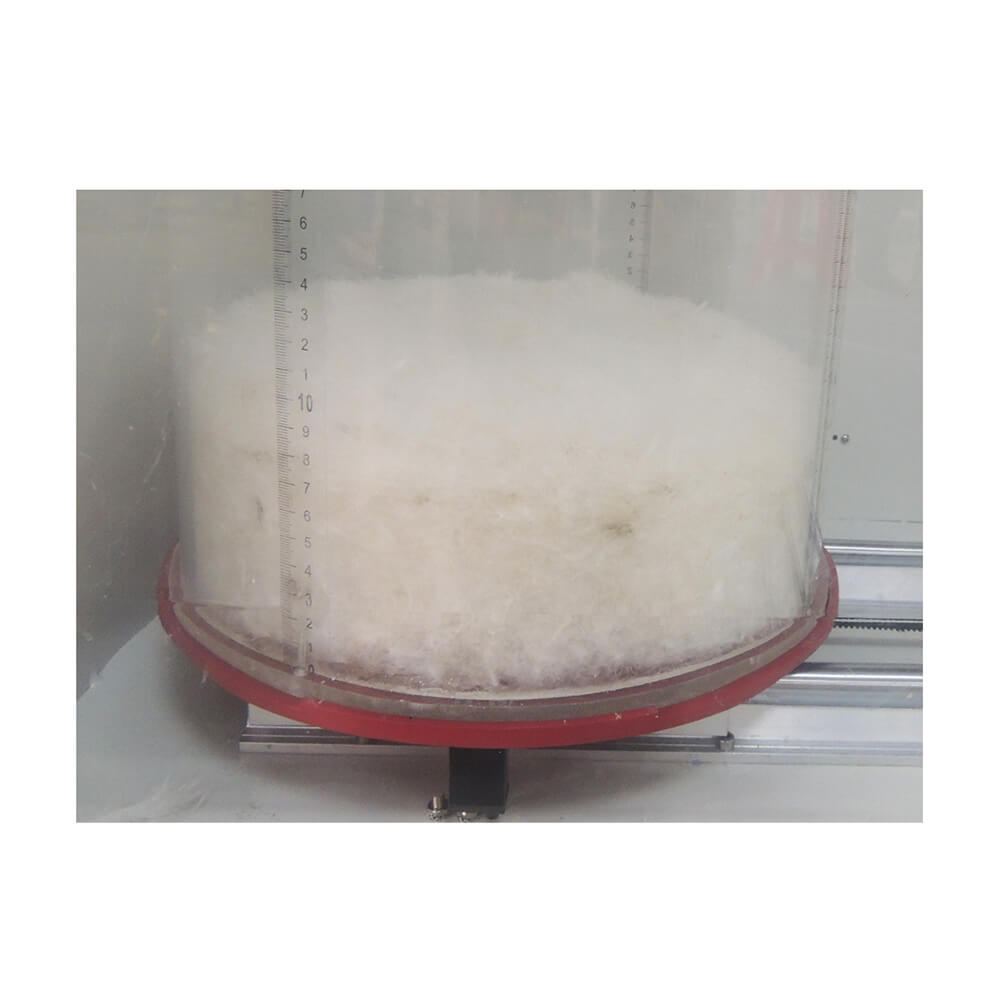

The test results are obtained by measuring the volume occupied by a certain amount of sample down feathers in a container of a certain diameter under constant weight pressure. When the start button is pressed, the weight plate moves down at a predetermined speed (eg.0.54m/min). When the platen touches the sample in the measuring cylinder, the speed of descent is reduced to less than 0.3 m/min due to the reaction force of the sample. At the same time, the loading time (1 min) starts and the test value (volume value) is continuously displayed. After the loading time countdown is over, the volume value tested is the final filling force value.

Functions of Feather & Down Filling Power Tester TF135

- Automatic blowing system

- Individual filter system design

- DC gear motor driving

- SCM controlling

- Touch screen operation

- Automatically lower the platen and display the height

Specifications

- Measuring speed: 520±20mm/min

- Measuring height: 750mm

- Measuring accuracy: 0.1mm

- Graduated cylinder internal diameter: 289±1mm

- Plunger and Measuring Rod: diameter: 285mm, weight: 94.3g

- Air velocity: (310±50)L/min

- Equipped with printer

Weight

| 50 kg |

Power

| 220 V | 50 Hz | 750 W |

Dimensions

| Length: 880 mm | Width: 740 mm | Height: 1460 mm |

| Length: 500 mm | Width: 550 mm | Height: 1200 mm |

Standards

| GB/T 14272 | GB/T 10288 | ||

| Optional Standards: | BS EN 12130 |

Welcome to TESTEX – a professional down-filling machine supplier – Feather & Down Filling Power Tester is on sale, contact us to get a detailed price quote for a series fill power meters.

2 reviews for Feather & Down Filling Power Tester TF135

You must be logged in to post a review.

Influencing Factors of the Feather & Down Filling Power

Whether feather down can return to its best initial state is directly related to the final test results of filling power during the testing process. All of the following factors affect the final test results:

Sampling methods for testing tests, initial state reduction methods for feather and down (oven reduction method, steam reduction method, etc.), the effects of temperature and humidity in a laboratory, test method and evaluation standard for filling power of down, and the effect of test equipment and personnel operation.

Feather and Down Filling Power Tester

Automatic feather & down filling power tester produced by our company is suitable for the filling power test of feather down and other fillers. It meets a variety of test standards. The main features are as follows:

1 The machine uses color touch-screen display and is easy to operate.

2 Unique filtration ventilation design, automatic switching of pile down and suction position to ensure that feathers will not fly in disorder and prevent operators from being harming.

3 The test speed can be set up, suitable for different standards, and the transmission structure adopts servo motor system, so that the height accuracy of bulkiness is more precise.

4 The original zero position system ensures the correctness of the data.

5 Using high precision sensor, ARM32 bit microprocessor, 16 bit A/D of AD company to collect Xingping, accurately sensing the position of pressure plate, accurate calculation of the test results, can apply a number of standards.

6 The automatic wind speed design system ensures that the down feather is in a state of natural fluffy, so that each measurement data has good authenticity and reproducibility.

7 The test process is completed by one button, and the test bucket is not replaced manually.

8 Automatic test, no need to manually replace the test bucket.

Test Method for Filling power of Down

At present, The existing test standards for bulkiness are: GB/T10288 (feather and down test method), FZ/T80001 (washed feather & down test method), BSEN12130 (feather down test method-fluffiness measurement), JISL1903 (feather down test method), and IDFB (official analysis method of international feather down bureau).

Here take the IDFB (official analysis method of international feather down bureau) as an example, introduce the brief operation process.

Treat the samples with oven reduction method, steam reduction method. After treatment, put 30g samples into the measuring barrel and blown loose for 5s with the blast equipment. It needs to be blown twice before the first test, and one blow before the next four tests. When press the start button, the weight plate moves down at a predetermined speed (0.54m/min). When the pressure plate comes into contact with the sample in the measuring tube, the decreasing speed of the pressure plate is reduced to less than 0.3m/min due to the reaction force of the sample. At the same time, the test values are continuously displayed after the loading time 1min and the test values are printed out. Test the samples five times and calculate the final results.

If you want to know more about feather down filling power tester, please contact us.

Roxanne Bedford –

Received it, very fast.

Ives Lancelot –

This is a perfect filling power tester. Thanks manufacturer.