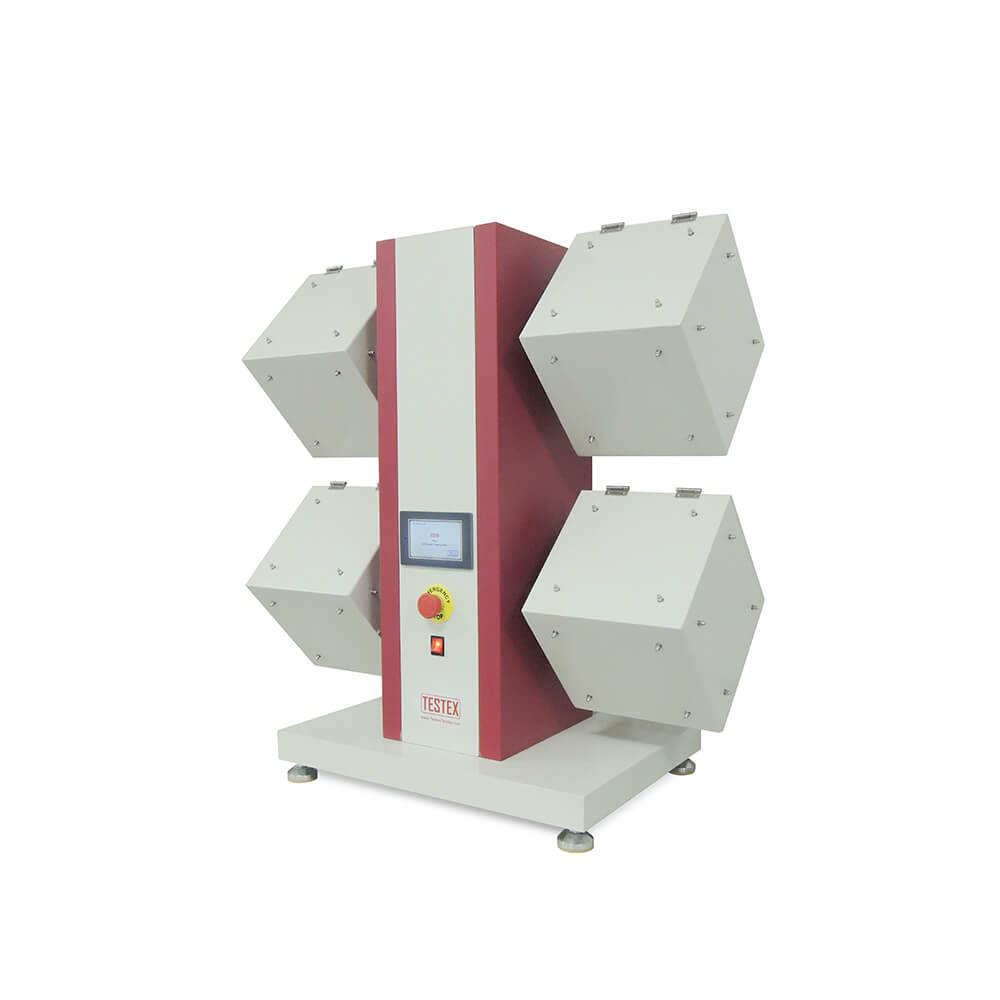

Fabric Pneumatic Bursting Tester TF142C

Fabric Pneumatic Bursting Tester is applied to determine the bursting pressure of fabrics using pneumatic test method, including knits, woven fabric, non-woven fabric, laminated fabric, and other craft-made fabric. Fabric Pneumatic Bursting Tester complies with ISO 13938-2, GB/T 7742.2, etc. Our Burst Strength Tester is accurate and efficient when you do bursting testing. We are dependable bursting strength tester manufacturers. Welcome to contact us for the Bursting Strength Tester price.

Description

Parameter

| Burst distension up to 70mm |

| Test Heads 100, 50, 10, 7.3 cm² (112.8, 79.8, 35.7, 30.5 mm Dia.) |

| Bursting pressure up to 800KPa, accuracy ≤ ±0.2%F•S, run rate ≤60Kpa/s |

| A lamp for clear observation, a transparent acrylic cover ensures safe operation |

| Touch screen control, automatic clamping and burst test, automatic calibration, automatic data processing |

| Optional accessories: diaphragms, pack of 10 |

Specification

| Model | TF142C |

| Standards | ISO 13938-2, GB/T 7742.2 |

| Power | 220/110 V, 50/60 Hz, 0.4~0.7 MPa |

| Weight | 180 Kg |

| Dimensions | 470 mm * 490 mm * 780 mm |

TESTEX – a professional textile testing instrument supplier – Fabric Pneumatic Bursting Tester is on sale, contact us to get a detailed price quote.

What is the Fabric Pneumatic Bursting Strength Tester?

The pneumatic Bursting Tester also named the pneumatic Bursting Strength Tester, is to determine the bursting pressure of fabrics, such as knits, woven fabric, non-woven fabric, laminated fabric, and other craft-made fabric. Besides, compared with the Digital Bursting Strength Tester, the pneumatic bursting strength apparatus enjoys a wider market. TESTEX is one of the Pneumatic Bursting Strength Tester Manufacturers, providing them at reasonable prices.

The pneumatic bursting tester controls the bursting return automatically instead of manual control by the mechanical drive. As a result, this bursting tester can avoid accidental damage to the rubber diaphragm. Besides, automatic data storage, processing, display, and printing, bursting distension measurement by the direct method rather than the traditional expansion method. With these improvements, the instrument test accuracy and its data reliability go to a higher level.

It can also measure the specimen extension prior to bursting. When testing, the instrument applies the pneumatic test method. In addition, the instrument can display the test curve in real time via the software during the test. Moreover, there is no worry about operation safety as the device owns a transparent acrylic cover. And the operation is easy since there are four most commonly applied test areas available.

What is fabric bursting strength?

In the process of use, the fabric is constantly subjected to a concentrated load of bursting, which causes the fabric to expand until it is damaged. For example, the elbows, knees and other parts of the clothing, this damage is called bursting strength.

As the fabric is subjected to bursting during use, the fabric extends longitudinally and shrinks horizontally. If only the tensile breaking strength of the fabric is tested, a single directional break does not actually reflect the wearing situation, so it must be tested in three directions: longitudinal, transverse and oblique. This problem can be solved by using a fabric bursting strength tester.

Fabric Bursting Strength Test Standard

- ISO 13938-1: Textiles – Bursting strength testing – Hydraulic method for determination of bursting strength and bursting distension

- ISO 13938-2: Textiles – Bursting strength testing – Pneumatic method for determination of bursting strength and bursting distension

- GB/T 7742: Textiles – Hydraulic method & Pneumatic method for determination of bursting strength and bursting distension

How to test the bursting strength of fabric?

Test principle

Clamp the test specimen to the expanding diaphragm with a circular clamping ring and apply air pressure to the underside of the diaphragm. As the air pressure increases, the fabric expands until it bursts, thus determining the bursting strength and expansion rate of the specimen.

Test process

- Before testing, prepare the fabric bursting strength tester, cut the specimen as required and conditioning it for use.

- Select a suitable test area according to requirements. 50 cm² is suitable for most fabrics.

- Set the test parameters for the fabric bursting strength tester.

- Place the specimen on the diaphragm and clamp the specimen to prevent slippage.

- Apply pressure and start the test. At the end of the test, record the relevant data and write a test report.

14 reviews for Fabric Pneumatic Bursting Tester TF142C

You must be logged in to post a review.

Why Do We Need to Test the Bursting Strength of the Fabric?

When the fabric is worn, it is often subjected to the concentrated load acting perpendicular on the fabric plane (such as knees, elbows, uppers, gloves, socks, etc.), and it bulges and expands until it is damaged, for example, parachute and filter bag have similar force and damage. This phenomenon is called a top break or burst. The ability of the fabric to resist bursting is called resistance to burst strength.

Some knitted fabrics, such as weft-knitted fabrics, have featured longitudinal extension and transverse shrinkage and they have a strong effect on each other. If a tensile test is applied to measuring fabric strength, the test must be made in radical, weft, and diagonal directions. The test of bursting strength is a comprehensive evaluation of fabric strength, only one test, which can provide information on multiple stretch features of the fabrics.

Terminology

Test area

area of the specimen in the circular gripper

Bursting pressure

The maximum pressure applied to the specimen held together with the lower gasket diaphragm until the specimen ruptures

Bursting strength

The pressure obtained by subtracting the diaphragm pressure from the average bursting pressure

Diaphragm pressure

The pressure required to apply to the diaphragm for achieving the average slope expansion of the specimen in the absence of the specimen

Bursting distension

The degree of expansion of the specimen under the bursting pressure, shown in the form of the bursting height

Height at burst

Distance between the upper surface of the specimen before expansion and the top of the specimen under the expansion pressure

Time to burst

Time required for expansion until specimen ruptures

Test report

Including general content and test results

General content

Specimen status

The model number of the bursting tester

The number of valid specimens ruptures close to the gripper, and discarded tests

The number of this part or description of the specimen and sampling procedure if needed

The situation of bursting and breaking performance of the specimen under observation

Test results

Average bursting strength

Average bursting height

A: You can know it from wikipedia of bursting strength.

Q: What is bursting strength tester principle?

A: 1. In this test the fabric sample is clamped over a rubber diaphragm by means of an annular clamping ring.

2. An increasing fluid pressure is applied to the underside of the diaphragm until the specimen bursts.

3. The operating fluid may be a liquid or a gas.

Q: What is bursting strength test procedure?

A: 1.The fabric sample is clamped over the rubber diaphragm.

2.The pressure in the fluid increases at such a rate that the specimen bursts within 20 ± 3 sec. (P1).

3.The height (extension) of the diaphragm is noted

4.Another test is carried out without a specimen.

5.The pressure to do this is noted and then deducted from the earlier reading.

6.(P1 - P2) is the actual bursting strength of the specimen.

Q: How do you calculate the bursting strength?

A: Bursting strength formula:

Bursting Strength (Kg / cm2) = Bursting Factor x GSM (gm / m2) / 1000

The bursting factor is proportionality constant and has the same value. To determine the bursting strength of a sample, a testing machine named bursting strength tester can be used. Once you get the bursting strength, the bursting factor can be derived from that.

Nick –

This is the second time I have bought textile testing equipment from them and they are very professional.

Leo –

We have been using the instrument for a long time and it still works very well and is a very good value deal.

Alan Woker –

so far so good, would consider a hydraulic bursting tester

Michael –

This bursting tester works well so far, would like to have the interface of the software improved

Ricardo –

Yes, just get what I need, highly recommend this bursting tester

Armstrong Walter –

Really good product. Highly recommended.

Ternence Dodd –

So far, so good!

Daniel –

This Fabric Pneumatic Bursting Tester is pretty accurate and the price is very reasonable. But the delivery time needs to be shortened.

Hayden Shakespeare –

The machine is not bad in appearance,with excellent performance in fabric testing.

Otis Kit –

Received it.The appearance of this bursting tester as beautiful as the picture shows.

Norma Timothy –

Price and performance of the fabric pneumatic bursting tester are favourable.

Wanda Lucius –

Satisfied with the manufacturer’s sevice as well as his bursting strength tester!

Esther Harvey –

Very impressed by this bursting strength tester manufacturer!

Curitis Field –

Works Great!!! Great seller, great communication

testextextile –

Thank you!Looking forward to the next cooperation