Influence of conventional finishing on fabric color Post-finishing is the last process of the…

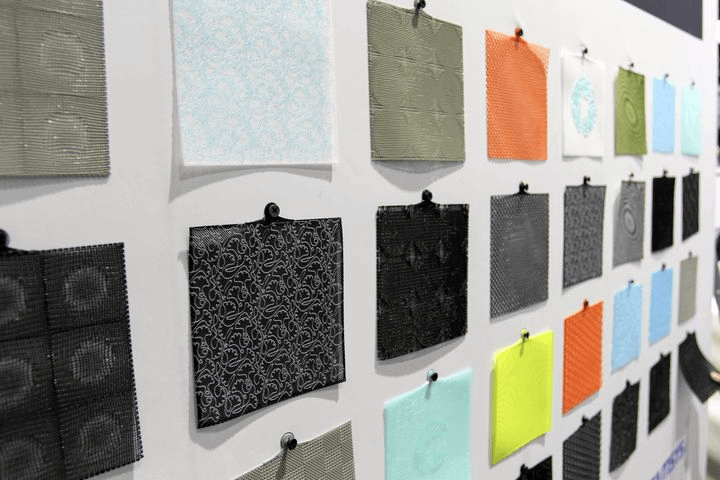

What is a non-woven fabric?

Non-woven fabric is not woven by a single yarn and knot together, but directly through the physical method of bonding together, so when you get your clothes sticky, you will find it is not a root of the thread. Non-woven fabric broke through the traditional textile principles, and it has a shorter process, faster production speed, high yield, low cost, wide use, more raw materials sources, and other features.

Its main purpose can be divided into:

1) Medical and health cloth: surgical clothing, protective clothing, disinfection cloth, masks, diapers, women’s sanitary napkins, etc .;

2) Home decoration with cloth: posted wall cloth, tablecloths, bed sheets, bedspreads, etc .;

3) With fitted cloth: lining, interlining, flakes, stereotypes cotton, synthetic leather base cloth, etc. all kinds;

4) Industrial fabrics: filter materials, insulation materials, cement bags, geotextiles, covering cloth, etc .;

5) Agricultural cloth: crop protection cloth, nursery cloth, irrigation cloth, insulation curtains, etc.

6) Other: space cotton, insulation materials, suction felt, smoke filter, tea bags and etc.

Classification of non-woven fabric:

1) Spun-lace non-woven fabrics

Spun-lace technology is the high-pressure fine water spray to one or more layers of a fiber network so that the fibers are tangled together and can be reinforced with certain strength.

2) Heat non-woven fabrics

The heat-bonded nonwoven fabric is a fiber-like structure added to a web or powder hot melt adhesive reinforcement material, then heated and melted and cooled to a cloth.

3) Pulp air-laid non-woven fabric

Air laid nonwoven fabrics can be called air laid dry papermaking nonwoven fabric. It uses air laid technology open wood pulp fiber board into a single fiber state, and then use the air flow method to make the fiber in the curtain, then reinforced fiber into cloth.

4) Wet non-woven fabrics

The wet nonwoven fabric is a fiber material that is placed in an aqueous medium and is opened into a single fiber, while mixing different fiber raw materials, made into fiber suspension slurry, suspended pulp transported into the body, the fibers are re-laid into cloth in the wet state.

5) Spun-bond non-woven fabrics

Spun-bond non-woven fabrics are formed after the polymer has been extruded and stretched to form a continuous filament, filament laying into a net, the web is passed through its own bonding, thermal bonding, chemical bonding, or mechanical reinforcement, So that the fiber can be made into a non-woven fabric.

6) Melt blown non-woven fabrics

Melt blown non-woven fabrics process: Polymer feed — melt extrusion — fiber formation — fiber cooling — into the network — reinforced into cloth.

7) Acupuncture non-woven fabrics

Acupuncture non-woven fabric is a dry non-woven fabric, Acupuncture non-woven fabric use puncture needle puncture; the fluffy web is reinforced into cloth.

8) Stitching non-woven fabric

Stitching non-woven fabric is a dry non-woven fabric; the stitching method is the use of warp knitting structure on the network, yarn layer, and non-woven materials (such as plastic sheet, plastic thin metal foil, etc.), or a combination thereof, to produce a nonwoven fabric.

This Post Has 16 Comments

Leave a Reply

You must be logged in to post a comment.

you are just amazing best article I found till date

Thank you for the blog article.Really looking forward to read more. Can read on.

A huge thankyou for the weblog article.Thanks all over again. Want longer.

Super-Duper blog! I am loving it!! Will be back later to read some more. I am taking your feeds also

Hiya very cool site!! Guy .. Excellent .. Wonderful .. I will bookmark your site and take the feeds also…I’m glad to find so many useful information right here within the put up, we’d like develop extra strategies on this regard, thanks for sharing.

Nice read, I just passed this onto a colleague who was doing a little research on that. And he actually bought me lunch because I found it for him smile Thus let me rephrase that: Thank you for lunch! “Whenever you have an efficient government you have a dictatorship.” by Harry S Truman.

Great ¡V I should certainly pronounce, impressed with your website. I had no trouble navigating through all tabs as well as related information ended up being truly simple to do to access. I recently found what I hoped for before you know it at all. Quite unusual. Is likely to appreciate it for those who add forums or something, website theme . a tones way for your customer to communicate. Nice task..

My brother suggested I may like this website. He used to be totally right. This submit truly made my day. You cann’t believe simply how so much time I had spent for this info! Thanks!

Really informative blog post.Really looking forward to read more. Cool.

Hey there just wanted to give you a quick heads up. The text in your content seem to be running off the screen in Chrome. I’m not sure if this is a format issue or something to do with web browser compatibility but I thought I’d post to let you know. The style and design look great though! Hope you get the issue solved soon. Many thanks

Im thankful for the article post.Really thank you! Much obliged.

Thanks for sharing, this is a fantastic article post.Really thank you! Will read on…

I really like and appreciate your article post. Really Cool.

Major thankies for the article.Thanks Again. Really Cool.

Say, you got a nice post.Thanks Again. Great.

Great post.Thanks Again. Will read on…